apid CNC Machining: A Detailed Overview

1. Executive Summary

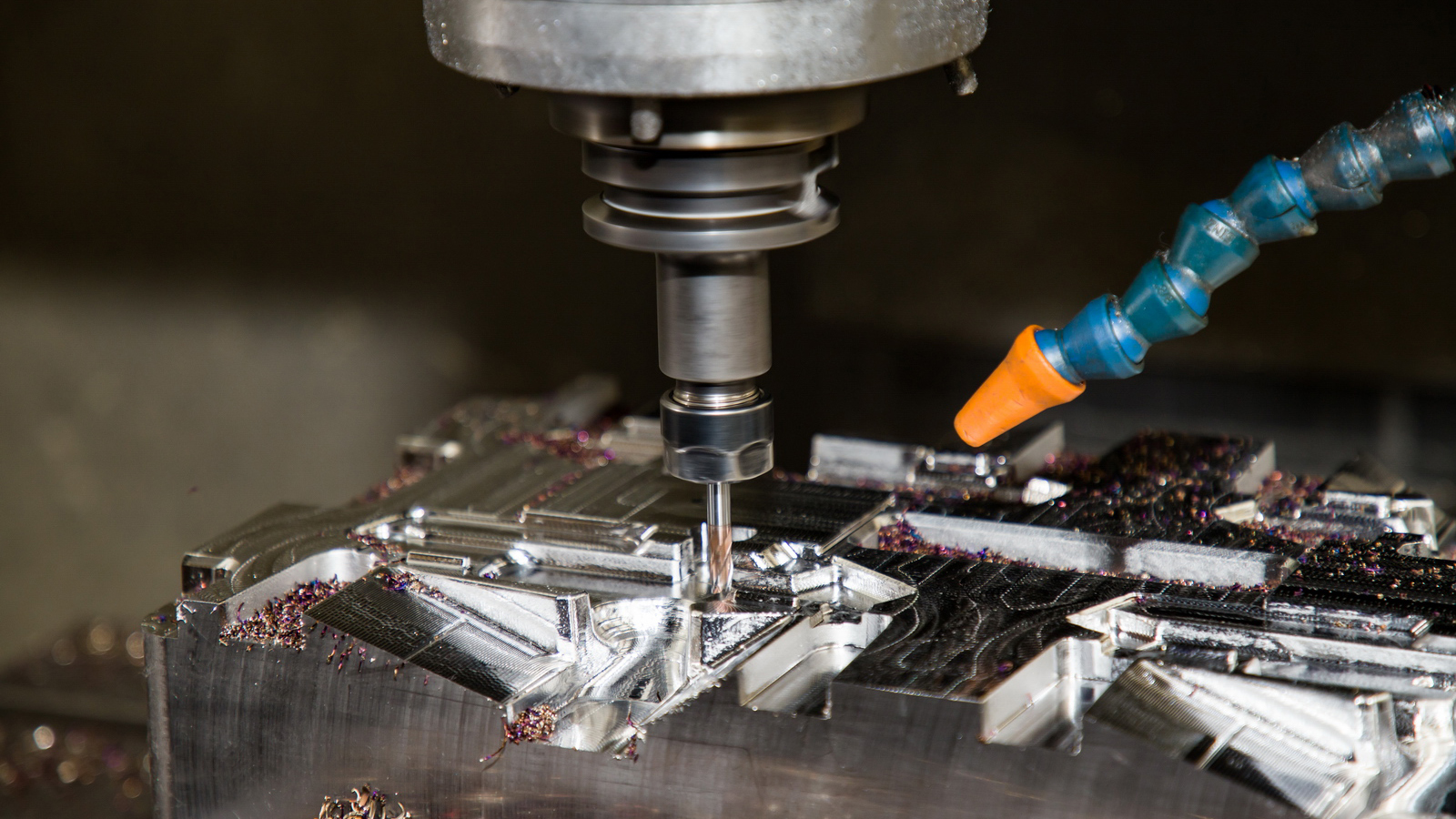

Rapid CNC Machining refers to the

use of Computer Numerical Control (CNC) machining technologies—specifically milling and turning—in an

accelerated, highly efficient manner to produce functional prototypes, tooling

components, and low-volume production parts in the shortest possible lead time.

It prioritizes speed-to-market over ultimate

per-part cost-efficiency, making it a cornerstone of agile manufacturing and

rapid prototyping.

While based on

traditional CNC processes, it is distinguished by optimized workflows,

strategic machining approaches, and a focus on eliminating bottlenecks.

2. Core Principles & Key Characteristics

The philosophy of Rapid CNC Machining is

built on several key principles:

3. The Rapid CNC Machining Workflow

The speed is

achieved by streamlining every stage of the process:

1. Digital Preparation

(CAD/CAM)

2. Machine Setup

3. Machining Execution

4. Post-Processing &

Finishing

4. Key Technologies & Equipment

5. Materials for Rapid CNC Machining

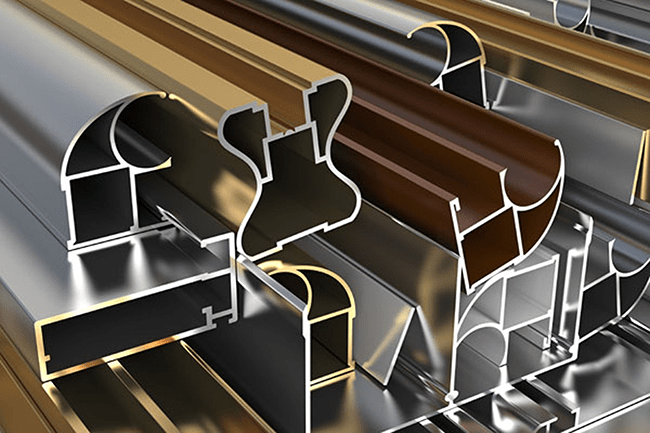

Material choice is a key speed factor. Softer

materials machine faster.

|

Material |

Machinability |

Typical Use Case |

|

Machining Wax / RenShape |

Excellent (Very Fast) |

Prototype Masters for silicone

molding (Vacuum Casting) or for visual models. |

|

Aluminum (6061, 7075) |

Excellent |

The most common material for

functional prototypes. Good strength-to-weight ratio, fast to machine. |

|

Plastics (POM/Delrin, Nylon, PC, ABS) |

Good |

For prototypes requiring electrical

insulation, low friction, or specific chemical resistance. |

|

Brass & Copper |

Good |

For aesthetic models, electrical

components, and parts requiring high thermal conductivity. |

|

Stainless Steel (304, 316) |

Fair (Slower) |

For high-strength, corrosion-resistant

functional prototypes that must mimic final part performance. |

|

Titanium (Ti-6Al-4V) |

Difficult (Slow) |

For aerospace, medical, and

high-performance applications where strength-to-weight ratio is critical. |

6. Advantages of Rapid CNC Machining

7. Limitations & Considerations

8. Comparison with Additive Manufacturing (3D Printing)

|

Feature |

Rapid CNC Machining |

Additive Manufacturing (e.g., SLA, SLS,

DMLS) |

|

Best For |

High-strength, functional parts. Precision

components. Parts that must be made from a specific metal/plastic. |

Highly complex geometries. Lattice

structures. Consolidating assemblies. Low-strength visual prototypes. |

|

Speed |

Very fast for lead time

(1-3 days). |

Fast for complex parts, but can be slow for

dense, large parts. |

|

Material Strength |

Excellent, isotropic (same

in all directions). |

Can be good, but often anisotropic (weaker in one

direction) and/or porous. |

|

Surface Finish |

Smooth directly from

the machine. |

Layered surface; often requires

post-processing to be smooth. |

|

Cost Driver |

Part complexity, material cost, machine

time. |

Part volume, support structures, and

post-processing. |

Conclusion

Rapid CNC Machining is an indispensable

technology in the product development toolkit. It fills the critical need for high-quality, durable, and material-accurate parts within a timeframe that supports iterative design and rapid market entry. When

performance, precision, and timing are paramount, Rapid CNC is often the

optimal manufacturing solution.