Contents

Mastars

3D printing

injection molding

rapid prototype

Injection Molding vs 3D Printing How to Choose?

When you are going to start a new project, you need to consider which manufacturing technology to be used. 3D printing or injection molding? We should fully understand their differences so that we can decide which technology is better for your project. In this article, we will compare the advantages and disadvantages of injection molding and 3D printing in terms of time cost, estimated budget, precision of parts and quantity of products to help you make better decision.

principles of injection Mouding and 3D printing

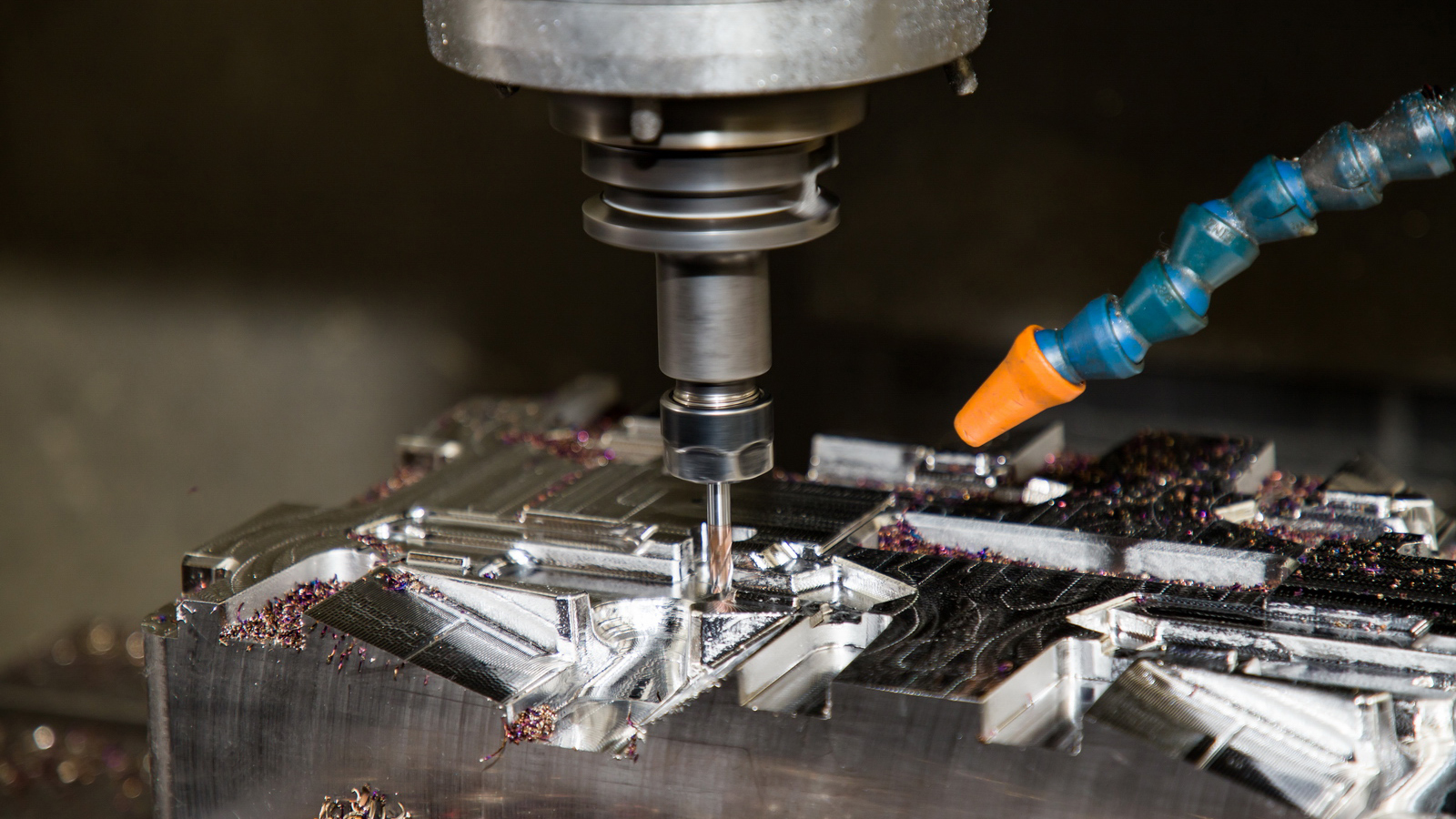

Injection mouding is a manufacturing process for producing parts by injecting molten material into a mold at specific temperature and high pressure. Material for the part is fed into a heated barrel, mixed (using a helical screw), and injected into a mould cavity, where it cools and hardens to the configuration of the cavity.

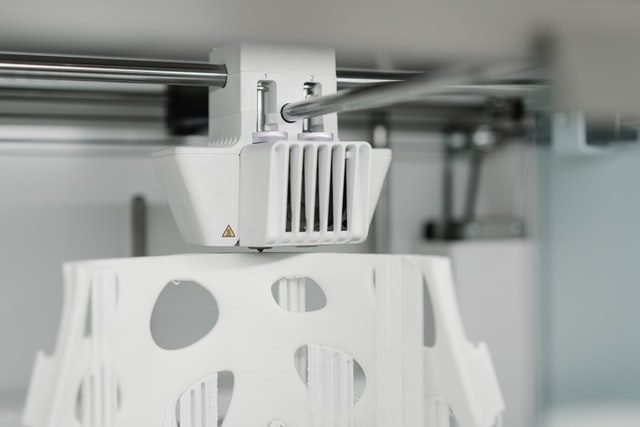

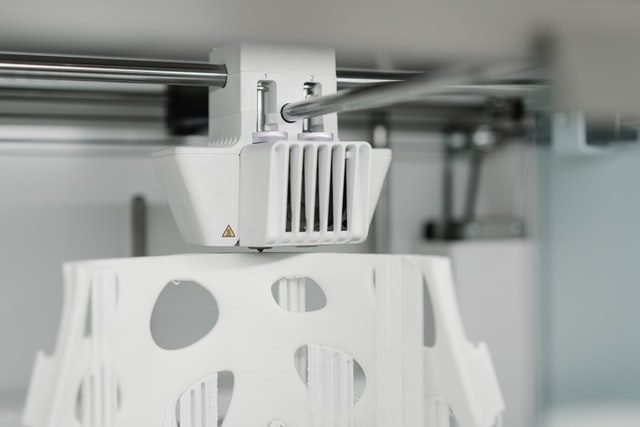

3D printing, or additive manufacturing, is the construction of a three-dimensional object from a CAD model or a digital 3D model. The term “3D printing” can refer to a variety of processes in which material is deposited, joined or solidified under computer control to create a three-dimensional object, with material being added together, typically layer by layer.

Differences between Injection Molding and 3D Printing

Injection molding and 3D printing are two common manufacturing processes, but they have different processing principles. Both of them can help you build

rapid prototype and carry out mass production. Both of them have advantages, which will add more benefits to your manufacturing process. So it is important to understand the differences between them.

Injection molding is a traditional industrial manufacturing technology. With this process, you can create the outline of the part by injecting the material into the cavity. This manufacturing technology allows your product to be rapidly molded by injecting molten material into a mold, and then the material cools down to a final solid shape. The materials for

injection molding is thermoplastic including ABS, PP, PS, PA, PVC, PC, POM, PMMA, etc.. The turnaround time is 5-7 weeks for simple parts, which is longer than 3D printing. The volume production is high with 1,000 parts at least per run. Injection molding is suited for those designs of final parts, which size are from the smallest components to entire body panels of cars.

3D printing means the entire manufacturing process is done by adding layers of material. You don’t need to create a mold to produce parts with a 3D printer. All you need is a 3D printed model file, and there are many different 3D printing technologies and materials available on the market. Materials for

3D printing can be SLA, SLS, SLM, etc.. 3D printing has applied in jewelry, footwear, industrial design, architecture, engineering and construction (AEC), automotive, aerospace, dental and medical industries, education, geographic information systems, civil engineering, firearms, and other fields. The turnaround time is only 1-2 weeks, and the volume production is low with about 100 parts or less per run. 3D printing is suited for those designs with frequent changes and for those relatively small plastic parts or components.

When to Use Injection Molding

To use this manufacturing technology you must have large production facilities. These

injection moulding machines contain a hopper, an injection plunger and a heating unit. Using the injection molding process to make molds is a bit expensive, and if your product requires multiple iterations, it can be very expensive to redo the molds each time. Because these molds are usually made of steel, making the changes is a bit complicated and not suitable for your prototyping development. However, if you plan to produce in large quantities, this is a great way to save time.

When to Use 3D Printing

Since the development of 3D printing, there have been dozens of printing technologies to choose from. If you need to 3D-print filaments, you can purchase a 3D printer, such as an FDM(Melt Deposition Modeling) printer. If there are higher requirements for materials and production process, we can also expand investment to buy more professional industrial-grade 3D printers, such as SLS(selective laser sintering) 3D printers. The purchase cost of a 3D printer depends on the specific needs of your company’s project and the budget situation. If you develop new products quickly, it will be more cost-effective.

Advantages of Injection Molding

Injection molding has great advantages as it can produce parts in large quantities with high precision and perfect repeatability. When using plastic injection molding, you can choose from a variety of materials, and each material can undergo thousands of changes by mixing with additives, which will lead to different properties. Based on plasticity and possibilities, it seems endless on weight, cost and flexibility.

As mentioned before, injection molding not only conduct mass-production, but also create very good details. Due to its repeatability, it is really easy to add details to an injection molded part. Injection molding makes it very easy to make parts with higher strength. In fact, the injection molding process can use fillers in the injection mold.

Advantages of 3D Printing

3D printing with variety of advantages that make it a true complement to traditional manufacturing techniques. The most important is that 3D printing is best suited for product iteration. 3D printing had been considered a

rapid prototyping technology for a long time, but now it is different, it has also become a reliable manufacturing technique. And build prototyping rapidly and easily is still one of the best advantages of 3D printing. With 3D printing, you can print the item for testing, and use 3D printing modeling software to make all these changes, then print again to confirm these changes. The flexibility of this process will help you improve your product design with less time and money.

To summarize, 3D printing and injection molding are complementary rather than competing technologies, and combining these two technologies appropriately can ultimately help to reduce the pre-production iteration cycle and produce better products.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210689

Fax: +86 755-8821 0685

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China