Full Guide for Selective Laser Sintering

Mastars' rapid prototyping service can provide various prototyping services according to customers' needs, verify your designed, provide fast, efficient and cost-effective services, and lay the foundation for future mass production of your products.

SLS is selective laser sintering. The metal materials used are treated mixed powders with low melting point metals or polymer materials. In the process of processing, the materials with low melting point melt, but the metal powders with high melting point do not melt. The bonding molding is realized by using the melted material, so the entity has pores and poor mechanical properties. If it needs to be used, it needs to be remelted at high temperature.

SLM is selective laser melting. As the name suggests, that is, in the process of processing, the powder is completely melted by laser without adhesive. The forming accuracy and mechanical properties are better than SLS. Compared with SLS, SLM is a new technology and an extension of SLS technology. The processes of these two methods are basically the same. The difference is that SLM uses metal powder instead of polymer in SLS as adhesive to directly form finished products with low porosity in one step, and there is no need to penetrate like SLS Technology.

Advantages:

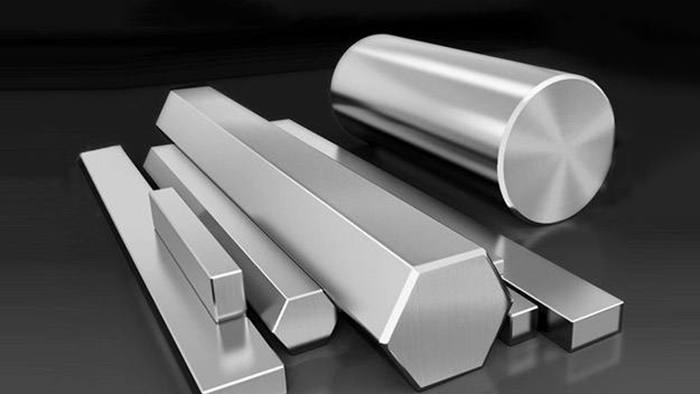

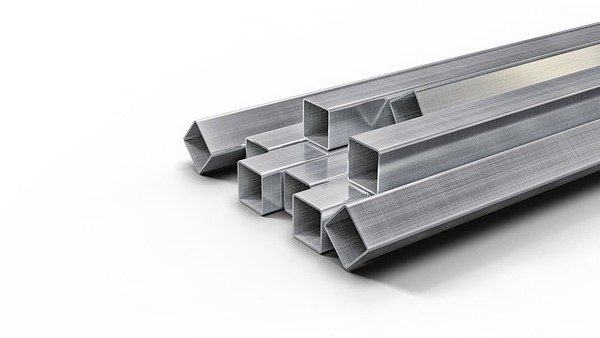

1. There are many materials that can be used in SLS. The materials that can be used include polymer, metal, ceramic, gypsum, nylon and other powders. However, due to the refinement of the market, metal materials will now be called SLM. At the same time, since nylon materials should account for 90% of the materials used in SLS in the market, we usually default that SLS is printed nylon materials.

2. Accuracy. Now the accuracy is normal, which is to achieve a tolerance of plus or minus 0.2mm.

3. It does not need support. It does not need support structure. The suspended layer in the lamination process can be directly supported by unsintered powder, which should be one of the biggest advantages of SLS.

4. High utilization rate of materials. Because there is no need to support and add a base, it has the highest material utilization among several common

3D printing technologies, and the price is relatively cheap, but it is more expensive than SLA.

Disadvantages:

1. Since the raw materials are powdery and the prototype is manufactured by heating and melting the material powder layer to realize layer by layer bonding, the prototype surface is strictly powdery, so the surface quality is not high. If you have high requirements for surface quality, you can choose SLA or a spraying treatment for SLS surface.

2. There is peculiar smell during sintering. In SLS process, the powder layer needs to be heated by laser to reach the melting state, and the polymer materials or powder particles will volatilize odor gas during laser sintering.

3. The processing time is relatively long. If SLS and SLA are printed for the same part, the delivery time of SLS will be relatively long. In fact, it is determined by the forming principle of SLS. SLS is sintering molding, and there should be 2 hours of preheating time before processing; After the part model is printed, it takes 5 to 10 hours to cool before it can be taken out of the powder cylinder.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210689

Fax: +86 755-8821 0685

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China