Injection molding technology has some special green properties, such as precision, environmental protection, resource saving, energy saving and low cost of mass production. It has become the first choice of solutions in automobile structural parts molding technology and the basic technology for molding technology innovation. It has been extended from general equipment and general technology to special equipment and special technology for automobile structural parts molding.|

In this article, we will first introduce the innovative technical concept of liquid

metal injection molding. Liquid metal, also known as amorphous alloy, has a low melting point, close to zero shrinkage, ultra rapid cooling and solidification, and there is no time for atoms to arrange and crystallize orderly during solidification. Therefore, it has many unique properties: excellent corrosion resistance, wear resistance, high strength, high ductility, high hardness, light weight and so on. In terms of design, liquid metal alloys can provide greater degrees of freedom than before. Based on the green plastic innovations such as the diversity, precision and life cycle of automotive parts, liquid metal has a broad application space in the automotive field.

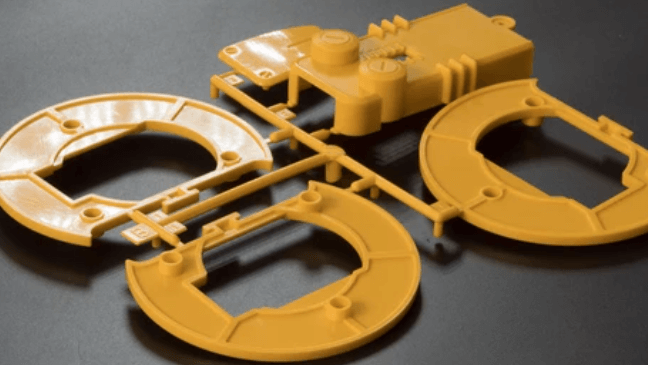

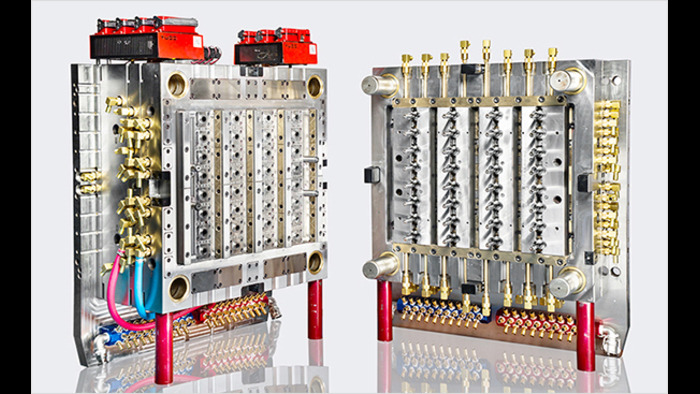

Among them, the liquid metal injection molding technology is an innovative development of injection molding technology. The parts injected from the model can often surpass the most accurate CNC technology, and can achieve near optical surface finish and high precision, which is the most important quality feature of liquid

metal injection molding process. Injection molding processing compared with metal injection molding (MIM) and CNC processing, injection molding of liquid metal creates conditions for realizing manufacturing concepts such as "higher efficiency and higher integration of automation and process". Liquid metal is processed by injection molding, which only needs a short cycle. Its production cycle time is between 2-3min, which is significantly shorter than that of CNC. At the same time, the gate material can be recycled without waste accumulation.

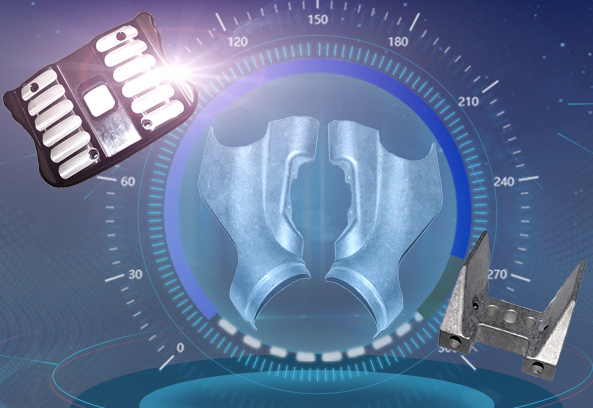

Liquid metal injection molding technology also brings new opportunities for the green development of automobiles. Automobile engine timing system, fuel injection nozzle, interior and exterior parts, safety components, pumps, sensors, heavy-duty connectors and other parts less than 400g can be made of liquid metal injection molded parts, which can not only obtain parts with excellent performance, but also obtain good economic benefits. It is a good choice for automobile parts manufacturing. Using the high hardness and high wear resistance of liquid metal to manufacture wear-resistant parts such as hydraulic cylinder, piston ring and fuel injection nozzle in automobile engine can greatly improve the service life of automobile.

The injection molding process of liquid metal should not only be regarded as a replacement process, but also as a molding process that can obtain unique properties through flexible design. Liquid metal is processed by injection molding to achieve one-step manufacturing of highly complex metal parts. Its precision and surface quality are far better than ordinary casting. Even complex three-dimensional shapes and very fine structures can be molded with excellent reproducibility and efficient material utilization, which has revolutionized the manufacturing of high-quality metal parts.

The technical barrier of liquid metal is very high, especially the problem of "bulk forming" has become the bottleneck restricting its large-scale application. Interior and exterior decoration parts, automobile parts with a weight of more than 400g, etc. belong to bulk forming, which means that if you want to promote liquid metal in a large area, you must master the core technology of bulk forming. Secondly, at present, few manufacturers are involved in liquid metals, and it is difficult to expand their production capacity rapidly. Liquid metal company of the United States has the most core, top and most extensive intellectual property rights (128 patents) related to liquid metal material formula and key processing technology in the world. It is a standard setter in the global liquid metal industry. With three core technologies including bulk forming process, material composition and equipment manufacturing, Yian technology is the only enterprise in the world that has the ability to form large bulk amorphous metals. After taking shares in the American liquid metal company and importing the bulk forming technology know-how to it, Yian technology will fundamentally solve its shortcomings with low-cost raw materials, molds, independently developed forming equipment and processing technology, It is expected to rapidly promote liquid metal products to the world.

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China