A few years ago, 3D printing with metal was only used in industry. Now all this has changed.

Metal 3D printing can be realized on desktop FDM 3D printers and more professional machines. It can not only produce high-quality parts, but also make the price more acceptable. In this article, let's take a look at all the technologies for 3D printing metal parts, and what technology you should choose to use to print metal parts.

At present, there are about 10 methods available for 3D printing of metal parts. These methods are roughly divided according to the form of raw materials and energy sources used, such as whether the material is metal wire, metal powder or metal wire. Some even use metal resins, metal rods and metal particles as raw materials, and each method can produce components with different properties. In the global

3D printing product library, more than a dozen Metal 3D printing technology devices have been included.

Choosing which metal technology to use requires consideration of factors such as part details, shape, size, strength, metal type, cost, printing speed and quantity. If we analyze from these aspects, each technology has its advantages and disadvantages. Unfortunately, there is no way to quickly, cheaply and perfectly 3D print super strong parts, so we should choose which technology to use according to the application needs.

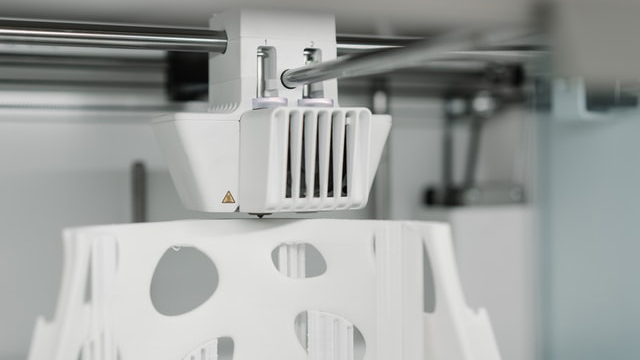

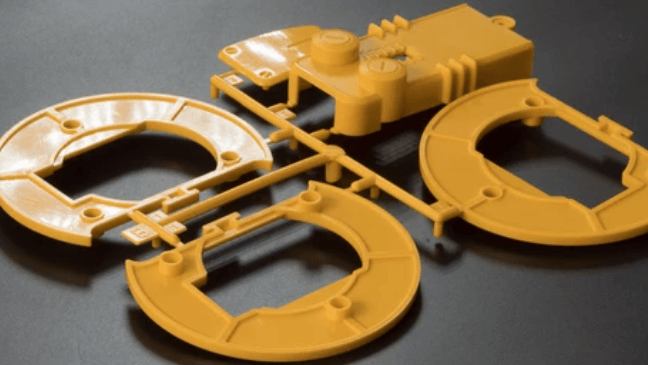

1. FDM and extrusion molding

2. selective laser melting (SLM)

3. electron beam melting (EBM)

4. metal binder spraying

5. arc wire feeding additive manufacturing (waam)

6. laser based directional energy deposition (DED)

7. electron beam oriented energy deposition (DED)

8. metal stereolithography Technology

9. cold spraying

10. micro nano metal 3D printing

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China