Mastars as a metal prototype maker, provides rapid sheet metal prototyping,rapid CNC service.rapid prototyping.

Sheet metal processing is a common processing method, which is essential in industry; It is a skill that operators should master; It is also an important process of sheet metal forming. Therefore, you must master these 9 terms of sheet metal processing, and then the sheet metal processing company Mastars will popularize them for you.

1. cutting: the technological process of different shapes of workpieces obtained from materials through plate cutting equipment. Generally speaking, CNC shearing machine is used to process the size, etc., and the cost of this method is relatively low.

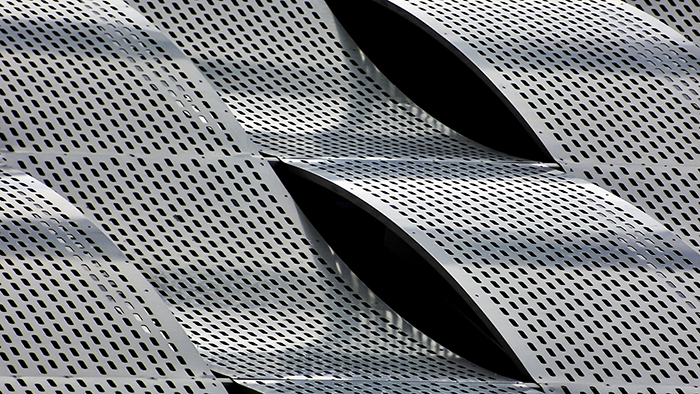

2. digital punching: it refers to a kind of operation of punching with a numerical control punch, which requires programming. It is processed on the front of the part. The important thing is to arrange the materials. If the materials are calculated, you can get the quantity you want at one time.

3. laser cutting: refers to the process of processing the workpiece through laser cutting, and the cost of laser cutting is relatively high.

4. cutting with cutting machine: it refers to the process of cutting with electric cutting machine. The requirements are not high, but there are certain risks.

5. sawing: refers to the process of cutting materials with a sawing machine, mostly profile materials.

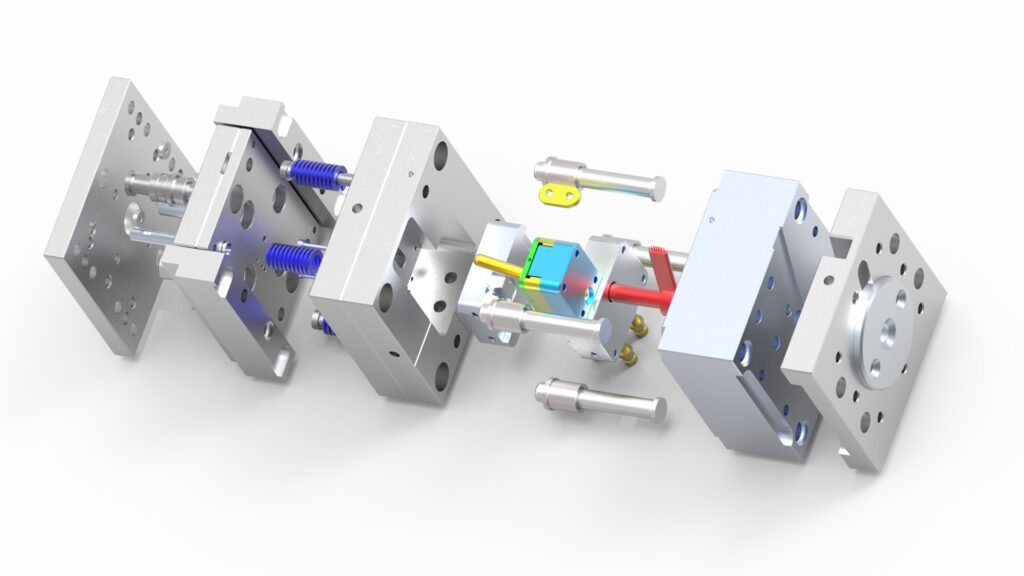

6. blanking: the product shape formed only by ordinary punch or mold processing.

7. punching: the process of processing with ordinary punches and moulds.

8. bending: the technological process of the workpiece formed by the bending machine.

9. punching and bending: it is installed with an ordinary punch and used for bending small and simple workpieces.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China