Pressure Die Casting: Professional Terminology

|

Term |

Definition & Context |

|

Pressure Die Casting |

A manufacturing process where molten metal

is injected under high pressure into a reusable steel mold (die). |

|

Hot-Chamber Die Casting |

A process where the injection mechanism is

immersed in a bath of molten metal. Ideal for low-melting-point alloys like

zinc and magnesium. |

|

Cold-Chamber Die Casting |

A process where molten metal is ladled into

a "cold" injection cylinder for each cycle. Used for

high-melting-point alloys like aluminum and brass. |

|

Die Casting Machine |

The equipment used to hold the die and

perform the injection and clamping actions. |

|

Clamping Unit |

The part of the machine that opens, closes,

and holds the two die halves together with immense force. |

|

Injection Unit |

The assembly that forces the molten metal

into the die. In a cold-chamber machine, this consists of the shot sleeve and

plunger. |

|

Clamp Force (Locking Force) |

The amount of force (measured in tons) the

machine exerts to keep the die closed against the injection pressure. It

determines the maximum projected area of a part that can be cast. |

|

Cycle Time |

The total time required to complete one

production cycle, from die closing to the next die closing. |

Category 2: The Die (Tooling)

|

Term |

Definition & Context |

|

Die (Tool) |

The reusable, precision-machined steel mold

that forms the casting. It is the most critical and expensive component. |

|

Cover Die (Fixed Die) |

The die half fastened to the stationary

platen of the machine. It usually contains the sprue hole or the shot sleeve

opening. |

|

Ejector Die (Moving Die) |

The die half fastened to the moving platen

of the machine. It contains the ejection system. |

|

Cavity |

The hollow impression or imprint in the die

that forms the external shape of the casting. |

|

Core |

A part of the die that forms the internal

features of the casting. Cores can be fixed or movable (slides). |

|

Parting Line (P/L) |

The plane or surface where the two die

halves meet. |

|

Slide (Angled Core) |

A movable core that moves perpendicular to

the die opening direction to form undercuts. It is actuated by an angle

pin or a hydraulic cylinder. |

|

Insert |

A separate piece of metal, often made of a

more wear-resistant material, inserted into the main die block to form a

specific, high-wear area. |

|

Vent |

A shallow channel or slot cut into the die

to allow air and gases to escape as the molten metal fills the cavity. |

|

Overflow Well |

A small cavity connected to the main part

cavity, designed to trap cold or oxidized metal that flows at the front of

the melt stream, improving the quality of the main casting. |

Category 3: The Injection System & Process

|

Term |

Definition & Context |

|

Shot |

A single cycle of injecting metal into the

die. The term also refers to the total volume of metal injected. |

|

Shot Sleeve (Cold Chamber) |

The horizontal cylinder in a cold-chamber

machine into which molten metal is ladled. The plunger moves through it to

force metal into the die. |

|

Plunger (Piston) |

The piston that pushes the molten metal

through the shot sleeve and into the die. |

|

Gooseneck (Hot-Chamber) |

The metal-filled tube in a hot-chamber

machine that connects the metal pot to the die. |

|

Slow Shot |

The first phase of the injection cycle

where the plunger moves slowly to allow metal to fill the shot sleeve without

trapping air. |

|

Fast Shot |

The second, high-speed phase where the

plunger accelerates to fill the die cavity rapidly before the metal

solidifies. |

|

Intensification (Final Pressure) |

The final phase where an extremely high

pressure is applied to the plunger after the cavity is filled. This pressure

compensates for shrinkage as the metal solidifies, creating a denser part. |

|

Biscuit |

The solidified plug of metal left in the

shot sleeve or gooseneck after the casting has solidified. |

|

Ladling |

The manual or automated process of

transferring molten metal from the holding furnace to the shot sleeve in a

cold-chamber machine. |

Category 4: Gating & Feeding System

|

Term |

Definition & Context |

|

Runner |

The channel system that carries the molten

metal from the sprue or biscuit to the gates of the part cavity. |

|

Gate |

The controlled, often small, entrance point

from the runner into the part cavity. Gate design is critical for controlling

metal flow and solidification. |

|

Sprue |

In a cold-chamber machine, the tapered

entrance from the shot sleeve to the runner system. In a hot-chamber machine,

it's the channel from the gooseneck. |

|

Ingate |

Another term for the gate. |

|

Overflow |

See Overflow Wellabove. |

|

Vent |

See Ventabove. |

Category 5: The Casting & Defects

|

Term |

Definition & Context |

|

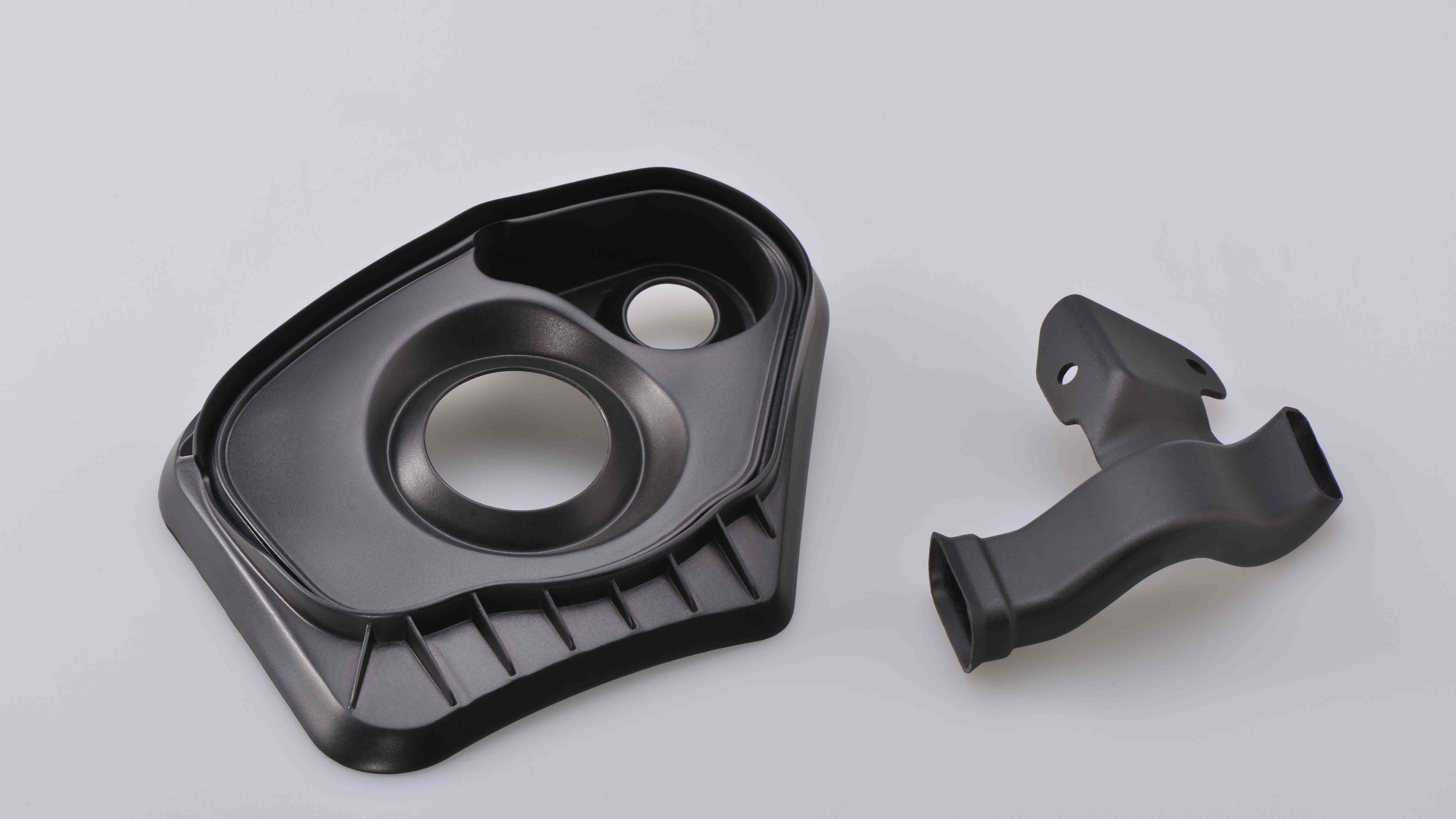

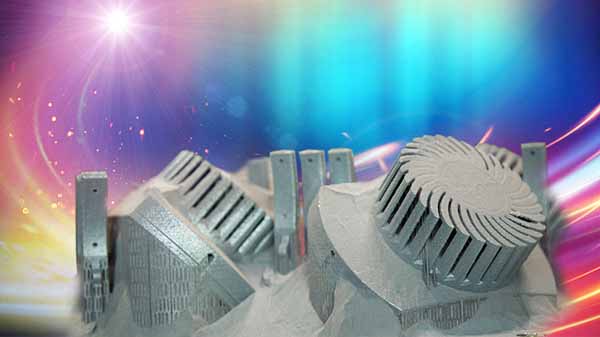

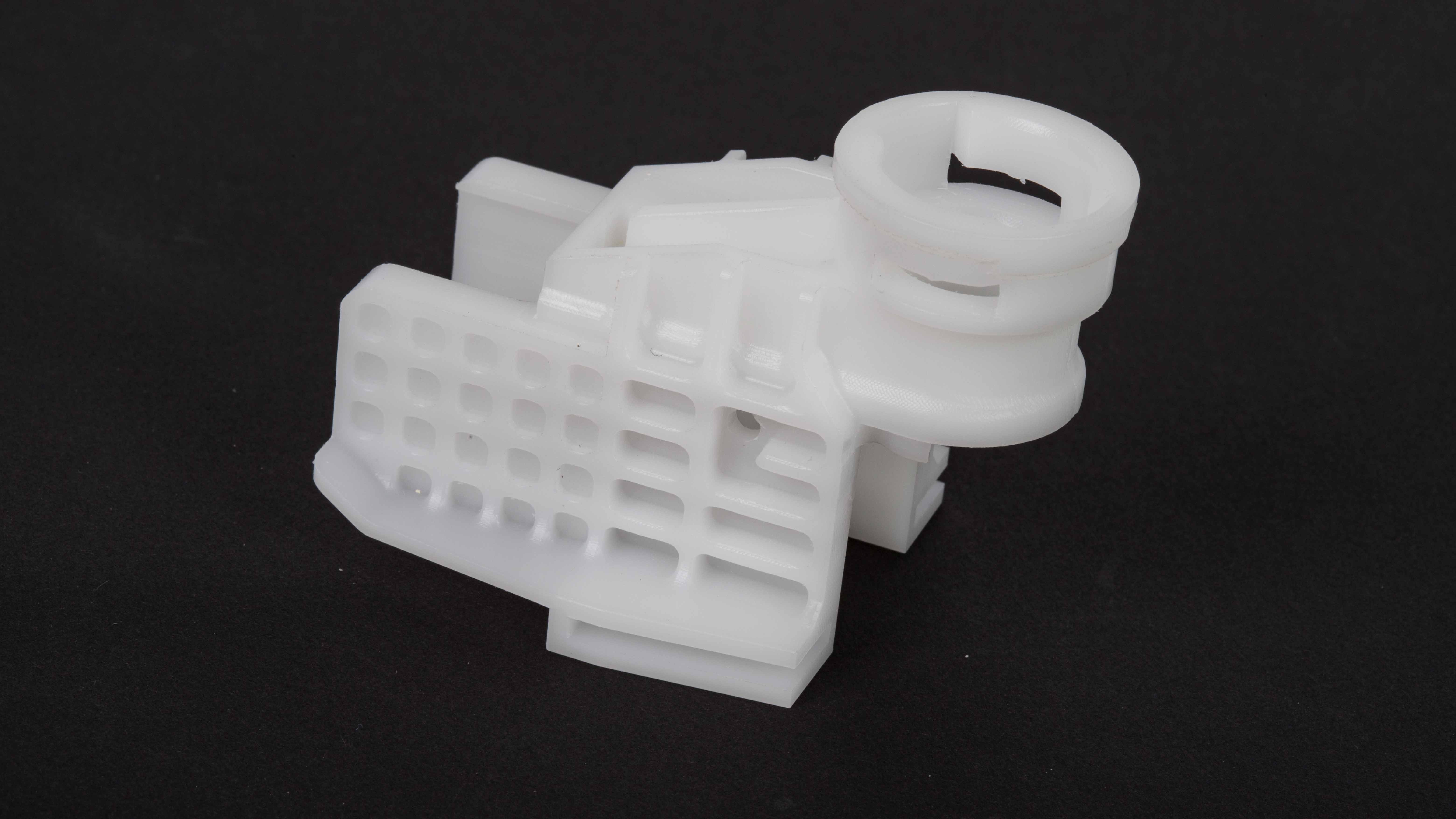

Casting |

The finished part that has been formed by

the die casting process. |

|

Flash (Fin) |

A thin web or fin of metal that escapes

between the die halves (at the parting line) or around cores and ejector

pins. Caused by excessive injection pressure or die wear. |

|

Ejector Pin Mark |

The impression left on the casting by the

ejector pins. |

|

Undercut |

A feature on the casting that prevents its

direct ejection from the die, requiring a slide mechanism. |

|

Porosity |

Voids or pores within the casting, caused

by trapped air or shrinkage during solidification. |

|

Cold Shut (Cold Flaw) |

A surface defect appearing as a line or

crack, caused when two streams of metal meet but do not fuse together

properly. |

|

Soldering |

A defect where the molten metal welds

itself to the die steel, causing severe damage to the die surface and the

casting. |

|

Blister |

A surface bubble or raised area caused by trapped

gas expanding during a subsequent finishing process like painting or powder

coating. |

Category 6: Secondary Operations

|

Term |

Definition & Context |

|

Trimming |

The operation of removing the flash,

runners, and overflows from the casting, typically done in a hydraulic press

with a trim die. |

|

Deburring |

The process of removing small sharp edges

(burrs) left after trimming, often by tumbling or manual grinding. |

|

Shot Blasting (Bead Blasting) |

Propelling a stream of abrasive media

(e.g., steel shot) at the casting to clean the surface and improve its

appearance. |

|

Machining |

Performing secondary operations like

drilling, tapping, or milling on the casting to achieve features that are

impractical to cast directly. |

|

Impregnation |

A sealing process where a polymer or

sealant is vacuum-forced into the porosity of a casting to make it

pressure-tight. |

This vocabulary provides a solid foundation

for communicating effectively with die casters, tooling engineers, and product

designers involved in the pressure die casting process.