Injection Tooling: Professional Terminology

Category 1: Fundamental Mold Types & Systems

|

Term |

Definition & Context |

|

Mold (Tool) |

The entire assembly that gives shape to

molten plastic. Called a "tool" in some regions. The core asset in

injection molding. |

|

Two-Plate Mold |

The simplest and most common mold design.

It has one parting line, with the runner system and part(s) on the same

plane. |

|

Three-Plate Mold |

A more complex mold with two parting lines.

One opens to eject the runner system, and a second opens to eject the part.

Allows for gating away from the part edge. |

|

Hot Runner Mold (Runnerless Mold) |

A system where the runners are kept hot and

molten inside a manifold block. No solid runner is ejected,

reducing waste and cycle time. |

|

Cold Runner Mold |

A mold where the entire runner system cools

and is ejected with the part. Includes Two-Plate and Three-Plate molds. |

|

Family Mold |

A single mold that produces multiple

different parts that form a product assembly. |

|

Insert Mold |

A mold designed to form plastic around a

pre-placed metal or other component (an "insert"). |

|

Prototype Mold |

A mold, often made from aluminum or mild steel,

built for speed and low cost to produce prototype parts. Shorter lifespan

than production molds. |

|

Production Mold |

A mold built from hardened

steel (e.g., H13, S7) for high-volume, long-term production. High cost and

long lead time. |

Category 2: Mold Structure & Plates

|

Term |

Definition & Context |

|

Mold Base |

A standardized, pre-manufactured frame that

holds the custom-machined core, cavity, and all other components. |

|

Cavity Plate ("A" Plate) |

The half of the mold usually attached to

the stationary platen of the injection machine. It contains the Cavity. |

|

Core Plate ("B" Plate) |

The half of the mold attached to the moving

platen. It contains the Core and the ejection system. |

|

Support Plate (Backing Plate) |

A thick plate that sits behind the

"B" plate to prevent it from deforming under high injection

pressure. |

|

Sprue Bushing (Sprue Bushing) |

A hardened steel component with a tapered

hole that connects the mold to the injection machine's nozzle. |

|

Leader Pins (Guide Pins) |

Precision pins that ensure the correct

alignment of the "A" and "B" halves as the mold closes. |

|

Leader Pin Bushings |

The hardened sleeves into which the leader

pins slide. |

Category 3: Part Formation & Surfaces

|

Term |

Definition & Context |

|

Cavity |

The hollow portion of the mold that forms

the external shape of the plastic part. |

|

Core |

The male portion of the mold that forms the

internal shape of the part (e.g., the inside of a bucket). |

|

Parting Line (P.L.) |

The line or plane where the two halves of

the mold meet. Often visible as a faint witness line on the finished part. |

|

Shut-off |

A raised land or sealing surface where two

mold components meet tightly to prevent plastic from leaking into another

area. Critical for holes and complex features. |

|

Draft |

A slight taper (typically 1°-3°) applied to

walls parallel to the mold opening direction. Essential for the part

to eject cleanly. |

|

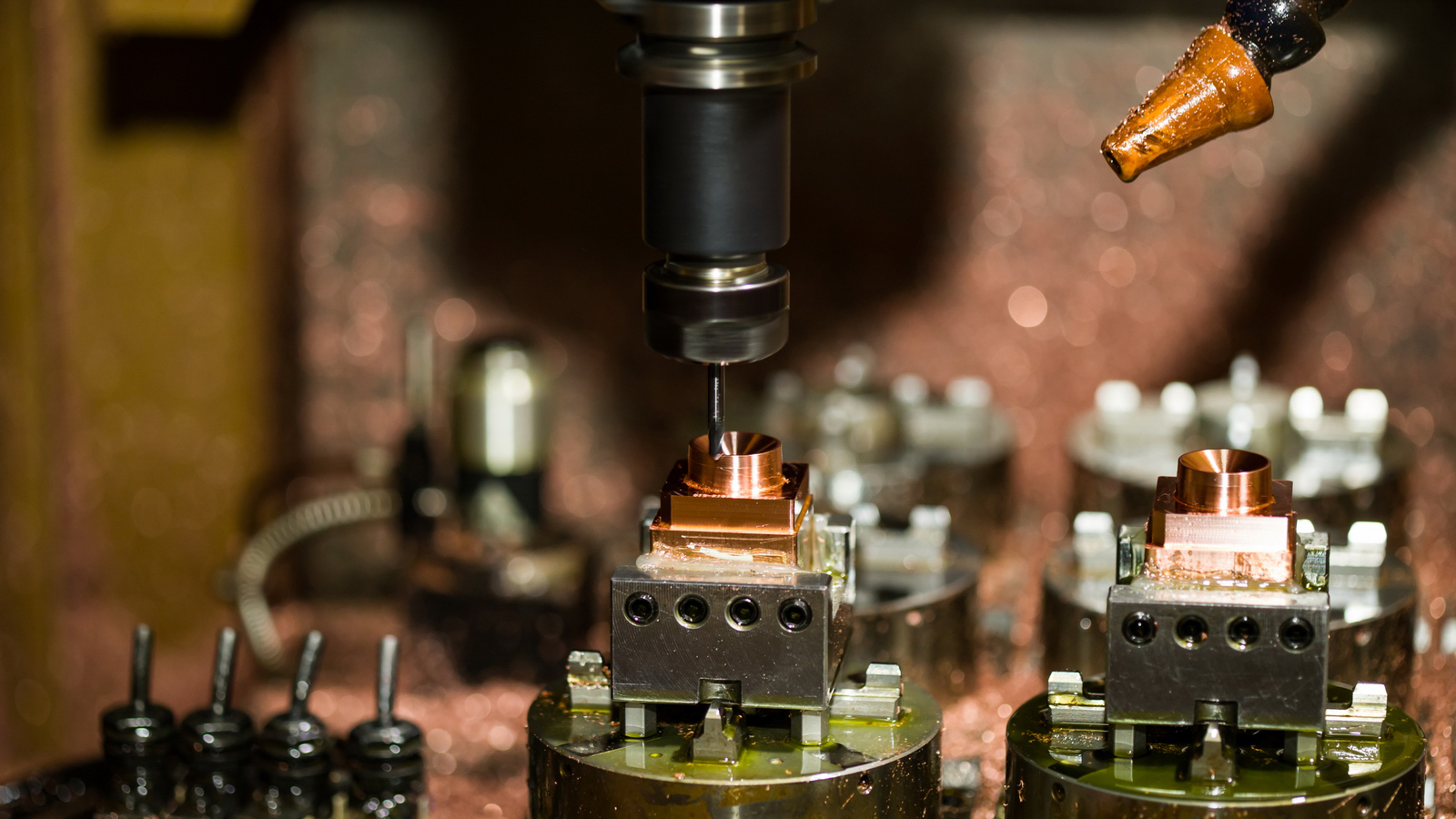

Texture (Mold Texture) |

A surface finish applied to the mold cavity

(e.g., via EDM, laser etching, chemical etching) to produce a desired

appearance on the part (e.g., leather, matte, gloss). |

|

Polishing |

The process of manually finishing the

cavity/core surface to a specific gloss level (e.g., SPI A1 mirror finish)

for part appearance and release. |

Category 4: Feed System (Gating & Runners)

|

Term |

Definition & Context |

|

Sprue |

The primary channel that delivers molten plastic

from the machine nozzle to the mold. |

|

Runner |

The channel system that distributes plastic

from the sprue to the various part cavities. |

|

Gate |

The small, controlled entrance from the

runner into the part cavity. Its design and location are critical. |

|

Cold Slug Well |

A cavity at the end of the sprue to trap

the initial, slightly cooled shot of plastic ("cold slug") before

it enters the part. |

|

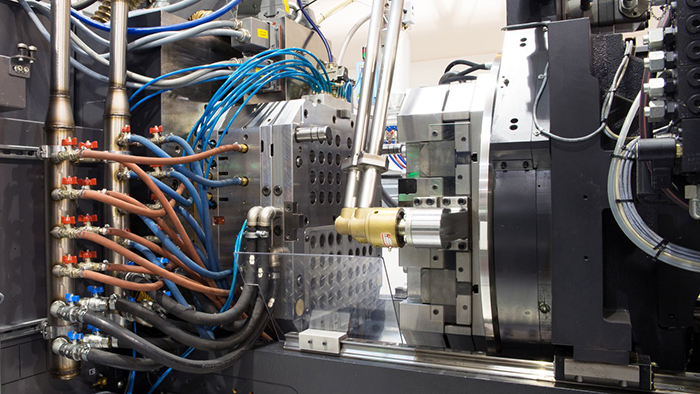

Manifold (Hot Runner) |

A heated block containing internal channels

that distribute molten plastic to the nozzles. |

|

Hot Nozzle (Hot Runner Nozzle) |

The heated tip that directly gates into the

part cavity in a hot runner system. |

|

Gate Vestige |

A small, often raised mark left on the part

after the gate is severed. |

Category 5: Ejection System

|

Term |

Definition & Context |

|

Ejector Housing |

The assembly of plates (ejector

plates) that hold the ejector pins and are pushed forward by the machine's

ejector rod. |

|

Ejector Pins |

The most common ejection component. Steel

pins that push the part off the core. |

|

Ejector Sleeves |

Hollow pins used to eject features that

surround a core pin (e.g., a boss around a hole). |

|

Blade Ejectors |

Thin, blade-like pins used to eject ribs or

other thin features. |

|

Stripper Plate |

A plate that encircles the core, used to

eject large, box-like parts or parts that cannot have pin marks. |

|

Return Pins (Ejector Return Pins) |

Pins that ensure the ejection system is

pushed back to its starting position as the mold closes. |

|

Early Ejector Return (Screw) |

A screw or pin that mechanically ensures

the ejector system is retracted before the mold closes completely. |

Category 6: Complex Features & Actions

|

Term |

Definition & Context |

|

Undercut |

Any part feature that prevents its direct

ejection from the mold, requiring a special mechanism. |

|

Lifter |

An angled component that moves with the

ejection system to form and then release an internal undercut. |

|

Slide (Cambered Slide) |

A component that moves perpendicular to the

mold opening direction to form an external undercut. It is driven by an angle

pin as the mold opens. |

|

Hydraulic Cylinder (for Slides) |

A hydraulic actuator used to power complex

or long-stroke slides instead of an angle pin. |

|

Insert |

A removable piece of steel that forms a

specific, often high-wear, detail in the mold. Allows for easy replacement. |

|

Core Pin |

A small pin used to form holes or standing

features (bosses) in the part. |

Category 7: Cooling & Venting

|

Term |

Definition & Context |

|

Cooling Channels (Water Lines) |

Passages drilled through the mold plates to

circulate a coolant (water or oil) and control the mold temperature. |

|

Baffle |

A deflector inserted into a deep cooling

channel to direct water flow for more efficient cooling. |

|

Bubbler |

A tube that directs coolant deep into a

core pin to cool an area that is difficult to reach. |

|

Heat Exchanger |

A device used to control the temperature of

the coolant. |

|

Vent |

A very shallow channel (0.015-0.03 mm) cut

into the mold to allow trapped air to escape during injection. Prevents burns

and short shots. |

Category 8: General Terminology

|

Term |

Definition & Context |

|

Mold Flow Analysis |

Computer simulation used to predict how

plastic will fill the mold, allowing for optimization of gating, cooling, and

the prevention of defects. |

|

Shot |

One complete cycle of the injection molding

machine, from clamp close to part ejection. |

|

Tool Trial / Sampling |

The initial test run of the mold in an

injection molding machine to debug it and produce first samples (T1

Samples). |

|

Mold Maintenance |

The regular process of cleaning,

inspecting, and repairing the mold to ensure consistent part quality and long

tool life. |

This vocabulary provides a solid foundation

for communicating effectively with mold designers, mold makers (toolmakers), and injection molding engineers.