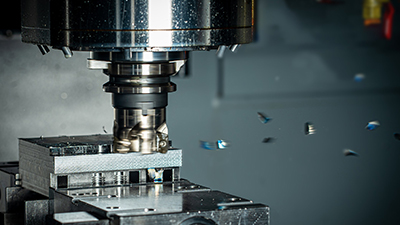

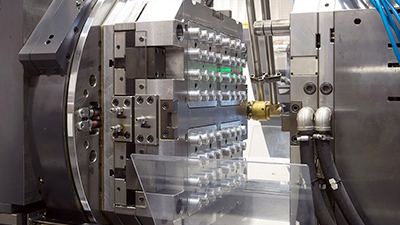

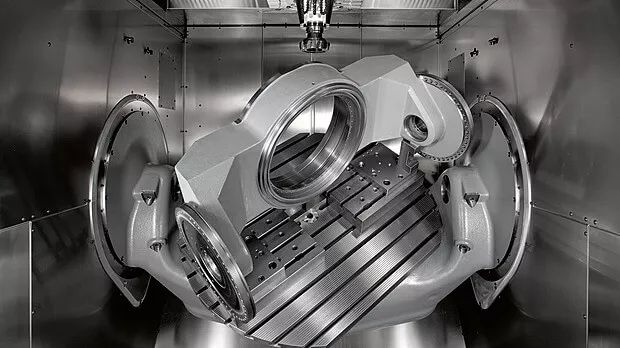

In modern industrial manufacturing, precision machining is becoming increasingly mature, and 5-axis CNC machine tools are more and more widely used in various fields. Whenever people encounter complex parts with irregular shapes, 5-axis machining technology is undoubtedly an important means to solve such problems. Mastars has German HERMLE C22, C42, C62 and other 5-axis machining centers, which have obvious advantages in the manufacture of various precision and complex industrial parts.

5-axis Machining refers to adding two rotary axes on the three common linear axes of X, Y, and Z. The two rotating axes in the three axes A, B and C have different motion modes to meet the technical requirements of various products. Under the control of the computer numerical control system, 5 axes are coordinated for machining at the same time. At present, various types of 5-axis CNC machining machine tools on the market have diverse mechanical structures, but there are mainly the following forms:

1. Two rotation coordinates directly control the direction of the tool axis (double swing head type)

2. The two coordinate axes are at the top of the tool, but the rotation axis is not perpendicular to the linear axis (vertical swing head type)

3. Two rotation coordinates directly control the rotation of the space (double turntable type)

4. The two coordinate axes are on the worktable, but the rotation axis is not perpendicular to the linear axis (vertical worktable type)

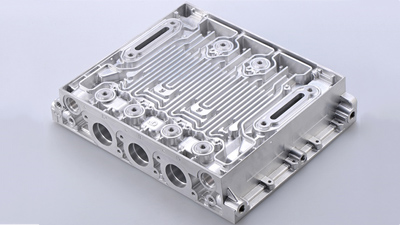

In general, 5-axis CNC is suitable for the parts that need complex processing, many processes, high requirements on products, and many types of processing equipment, and can only be completed by multiple processing. Whether it is box-type parts, complex curved surfaces or special-shaped parts, it can be processed by 5-axis CNC machine tools.

5-axis CNC is the most difficult and widely used technology in CNC technology. It integrates computer control, high-performance servo drive and precision machining technology, and is applied to efficient and precise automatic machining of complex surfaces. Due to its special status, especially its important influence on aviation, aerospace, and military industries, as well as its technical complexity, 5-axis numerical control technology is regarded as a symbol of the automation technology level of a country's production equipment in the world.