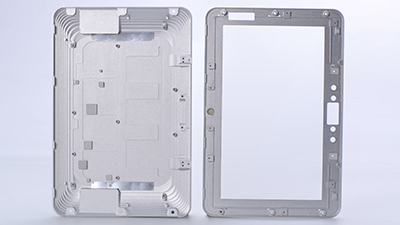

Mastars will use rapid prototyping mold and other techniques in the production of rapid prototyping. CNC is a commonly used processing technology, and it is understandable that the cost of CNC manufacturing prototyping is relatively high. After all, it requires highly qualified experts, specialized equipment, and sometimes the use of expensive alloys. Reasonable planning during the design phase can reduce the total project cost of CNC prototyping design.

1. Large pieces of metal. The basic principle of custom CNC machining is that, you need to cut a lot of metal at first. In the prototyping and small batch industries, the mass often referred to as a "blank" is actually greater (in some cases, up to five times larger) than the total mass of the final part. That's why it's important to choose the right alloy, because you're actually paying 3-4 times the mass of the part.

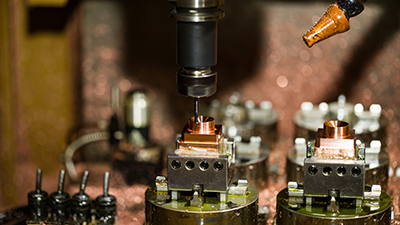

2. Preparation time. Once the technical drawings are in CNC service, there is an inevitable preparation phase when preparing the machining equipment, writing the program and making or assembling the mold.

3. Processing time. Once the preparation is complete, it is machined. The main parameter in CNC rapid prototyping is the total time required for the entire process. It includes the time to perform the actual cut, change the tool, load and unload the part, and to move the parts between the CNC machines if necessary. This fee is by far the largest on the list.

After analyzing the cost of CNC prototyping, we can make some improvements to help you reduce the cost of CNC prototyping for your project.

Many people don't think carefully about the right materials at first. They either use the default construction steel, or use something like titanium or stainless steel to prevent rusting. If you have a large number of workpieces to be machined, aluminum is the best choice as this material can be machined faster and the economic benefits of machining time will make up for the extra machining costs.

Another problem is when you need a certain special material property, for example, you need a material that can withstand high temperatures of 800 degrees Celsius, and you choose a material that can reach 950 degrees Celsius, which is difficult and much more expensive, so it is no need for that extra 150 degrees Celsius.

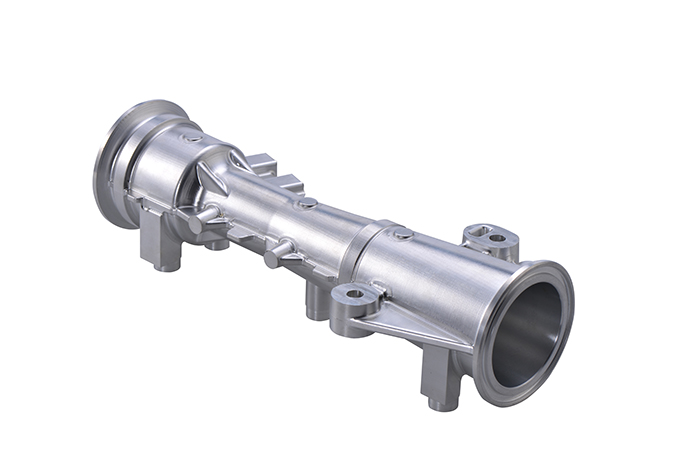

Avoid complex surfaces

If your choice is rapid prototyping, CNC machining of complex surfaces with a high finish is not recommended unless there is a real need for it. The reason for this is that complex surfaces are often finished by small end mills with spherical tips. Its stride is very small (about 0.05-0.1mm) and must abut the entire surface from the same side (there are small ribs if it goes both ways). When the area of the complex surface is large, it will take several hours to complete.