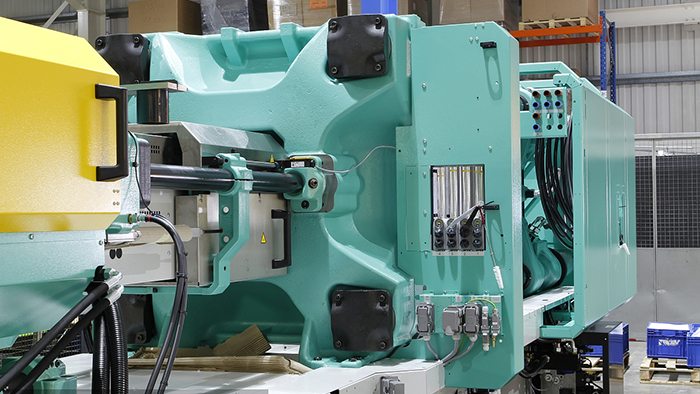

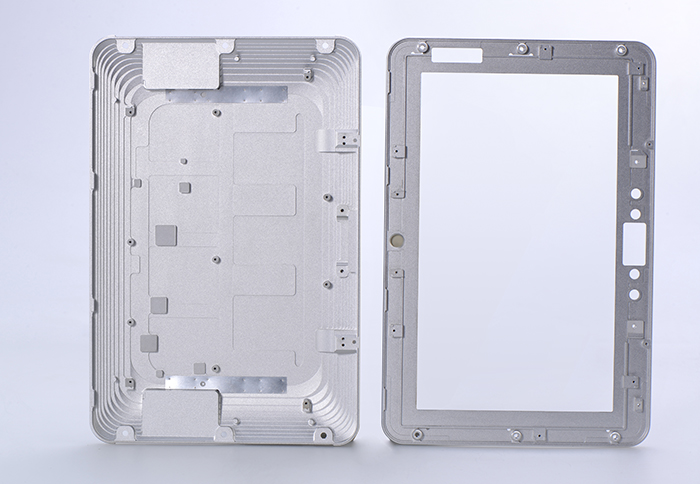

From the previous chapter, we have known that CNC machining processing plays a very important role in modern industrial manufacturing. Mastars uses CNC technology to make prototypings and functional parts, providing customers with rapid prototyping services and high-precision parts production.Mastars has the world's leading CNC machine tools and leads the industry in CNC processing industry.

Now let's analyze the advantages and disadvantages of CNC machining.

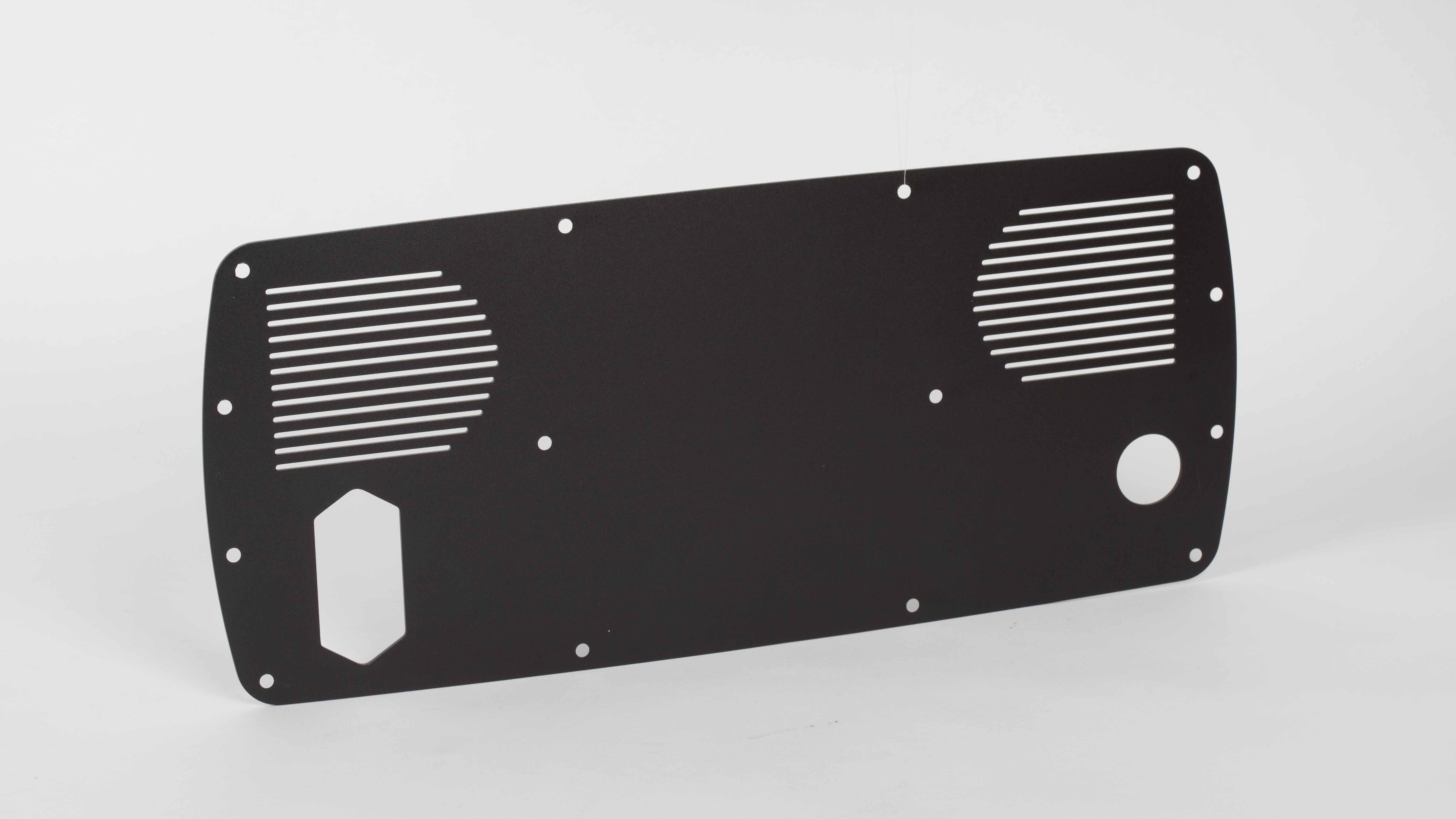

1. There are many high-performance materials that can be used, and the choice of materials is large. The products produced have good physical and chemical properties.

2. High degree of automation and high production efficiency. Except for manual clamping of blanks, the rest of the machining processes can be automatically completed by CNC. CNC machining reduces the labor intensity of the operator and improves the labor conditions; it eliminates the processes and auxiliary operations such as scribing, multiple clamping and positioning, and inspecting, and effectively improves the production efficiency.

3. CNC has strong adaptability to machining objects. When changing the processing object, in addition to changing the tool and solving the blank clamping method, it only needs to be reprogrammed, and no other complex adjustments are required, thus shortening the production preparation cycle of the product, and it is very suitable for new product development and modification.

4. High machining precision and stable quality. The machining dimensional precision is between 0.005 and 0.01 mm, which is not affected by the complexity of the parts. Since most of the operations are done automatically by the machine tool, human error is eliminated and the consistency of the size of batch parts is improved. At the same time, the precision-controlled machine tool also adopts a position detection device, which further improves the precision of CNC machining.

1. Due to the material reduction processing method, there is a lot of waste of materials and high material cost, which is in contrast to 3D printing.

2. The cost of machine tool equipment is expensive, and maintenance personnel are required to have a high level.

3. The processing route is not easy to control and cannot be as intuitive as ordinary machine tools.