Contents

A Full Guide To 5 Axis CNC Machining

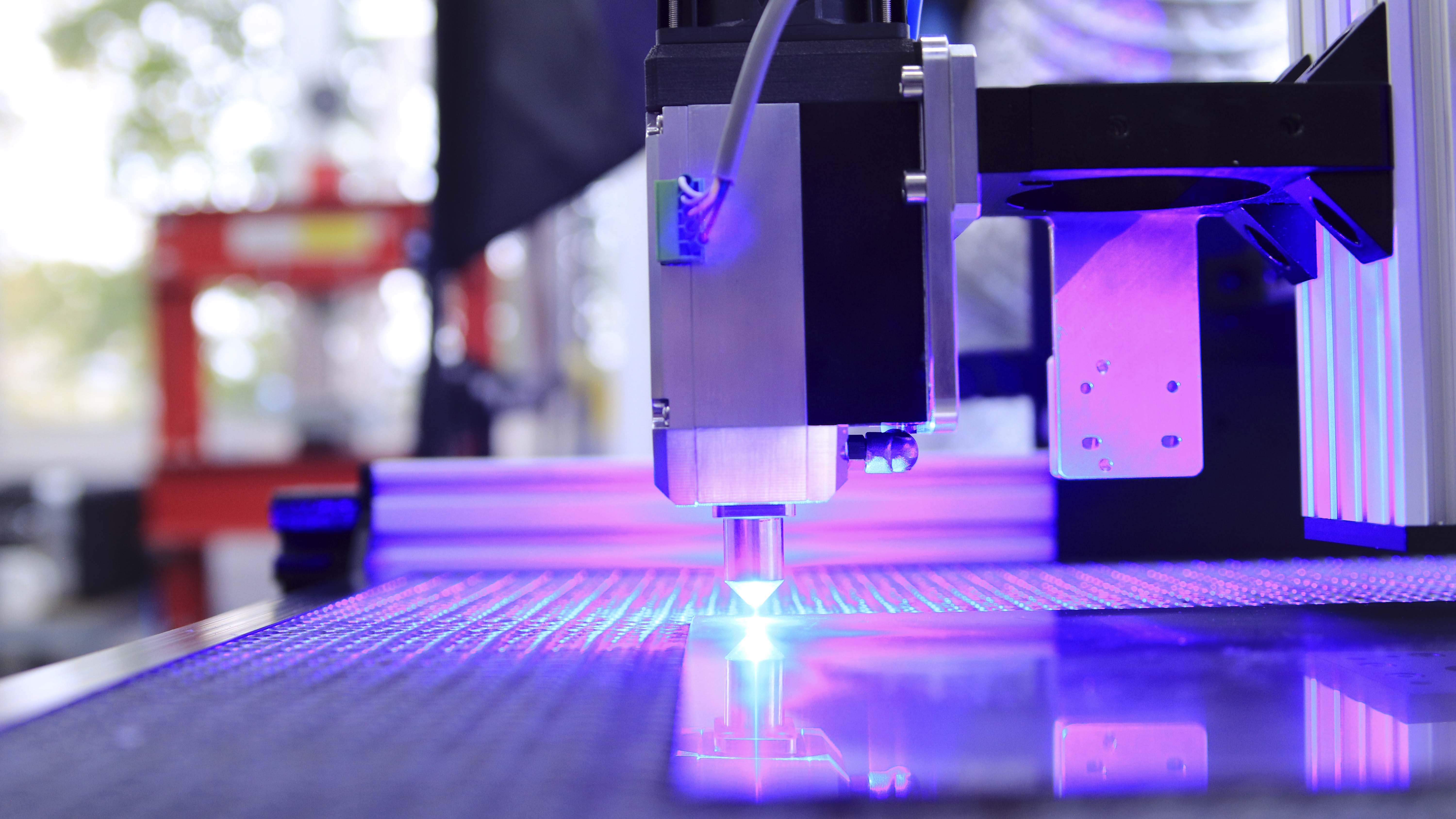

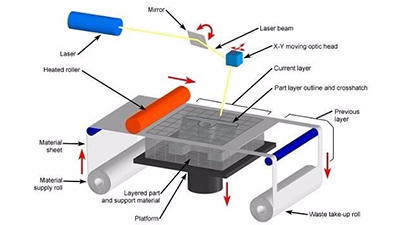

When it comes to CNC machining services, you will think of 5-axis CNC machining. Choosing the right processing solution will lead to the success of production.Likely while 3D Printing technologies are advancing at a fast rate, not all materials can be printed with a traditional setup. CNC machining is a program used in most manufacturing operations and is widely used in most industries. CNC stands for computer digital control, which deals with the use of one or more computers to manage the operation of different machine tools, such as lathes, routers and milling machines.

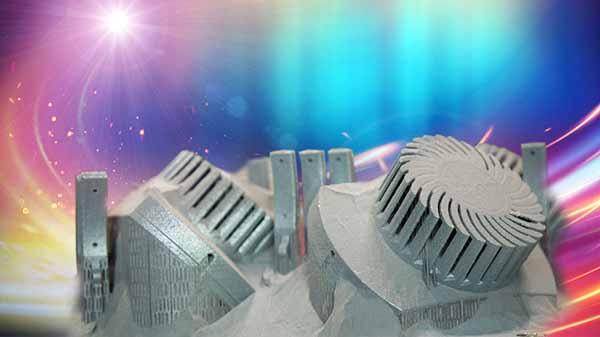

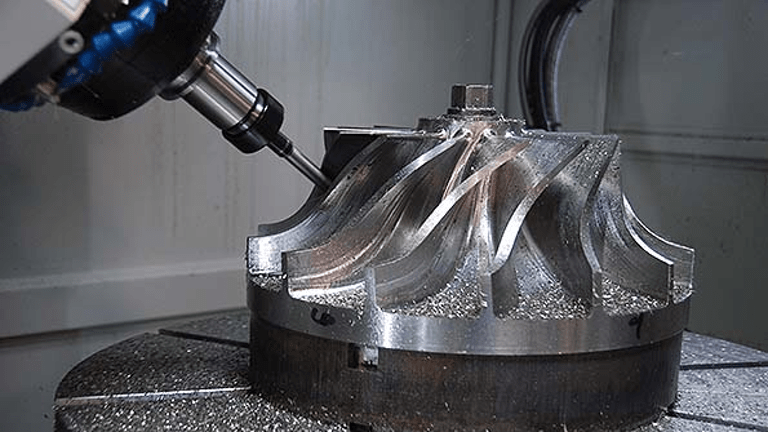

5-axis CNC machining is an absolutely excellent CNC machining, which can be used to produce parts and final products from a variety of materials such as plastic and metal.

However, sometimes when referring to specific 5-axis CNC processing, most people's first impression is: high technology, expensive price and difficult operation, but is 5-axis processing really like this? The following paragraphs will introduce you to 5-axis CNC machining from three important aspects.

What Is 5 Axis CNC Machining?

To properly understand what 5 Axis CNC Machining is we first need to go over the different elements that make it name. The most important aspect to understand upfront is what exactly is CNC Machining.

This is a program that involves using CNC to move cutting equipment or different parts on five different axes at the same time. This provides space for the production of very complex parts, which is why 5-axis CNC milling is very common in aerospace operations. It is a factor to reduce the time required to use the CNC axis to complete the actual production process.

The ability to avoid collision with parts of fixed equipment by rotating worktable or cutting tool provides space for rapid access to part geometry is another influencing factor. Finally, rotate the workbench or cutting equipment to maintain the best cutting position and consistent chip load, so as to improve the service life or service life of the equipment.

"5" for 5-axis machining

Five axis machining is a way of NC machining. The machining center we usually use is a three-axis machining center. Axis 3 refers to the X axis, Y axis and Z axis of the machining center. The five axis machining center adds two rotation axes to the three common linear axes of X, y and Z, which are also called the fourth axis and the fifth axis. A. Two of the three shafts B and C have different movement modes in the vertical machine to meet the technical requirements of various products.

Five main forms of five axis machine

There are many kinds of five axis machine tools in horizontal machining center, mainly in the following five forms: one is the form of double rotary head, and the two rotation coordinates directly control the direction of cutter axis; 2. In the form of drooping rotating head, the two coordinate axes are at the top of the tool, but the rotating axis is not perpendicular to the linear axis; The third is the form of double turntable, and the two rotation coordinates directly control the spatial rotation; 4. The two axes are on the worktable, but the rotation axis is not perpendicular to the axis; The fifth is a swing and a rotation. There are two rotation coordinates, one on the tool and one on the workpiece.

Mastars

Industries CO., LTD

Email:

marketing@mastars.com

Tel: +86

755-88210689

Fax: +86

755-8821 0685

Add: Building

6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City,

Guangdong, China