Mastars provides high-quality rapid prototype services to customers through advanced 3D printing technology, CNC machining and mold production.

Previous: the principles of SLS and SLA in 3D printing technology.

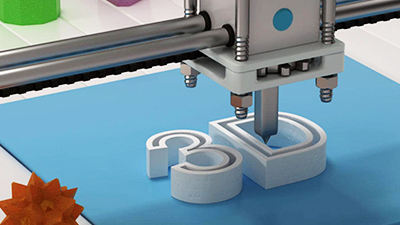

3D printing is becoming more and more widely used in all walks of life. 3D printing services create parts by layering materials one layer at a time, a form of additive manufacturing. The printer's print head moves along a path and applies molten material, building the part layer by layer, and as the material hardens, they stick together to form the final product.

This method can produce parts of almost any geometry. Plastics and metals are the main materials, especially plastics are more popular and are used in almost all industries. There are many types of plastics with different properties and characteristics. Metal materials are more often used in medicine and mechanical engineering. In addition, materials with new properties are released every year.

Like any other type of manufacturing, 3D printing has its advantages and limitations.

Advantages:

1. Any complex product can be created without gluing, assembly. Moreover, the complexity of the product does not significantly increase the manufacturing cost, which will change the traditional way of calculating the manufacturing cost.

2. A large number of printing materials are available. There are more than 500 materials that can be used for printing, including plastics, resins, plaster, ceramics and sand. You can also print with titanium, aluminum, steel powder and even precious metals.

3. Rapid production, rapid design verification, greatly shortening the customer's turnover cycle.

4. Low production cost. Compared with CNC machining, mold machining, etc., 3D printing technology does not require machining or any molds, and can directly generate parts of any shape from computer graphics data. This can greatly shorten the product development cycle, improve productivity and reduce production costs. Compared with traditional technologies, 3D printing technology reduces costs by eliminating the production line.

5. Save materials. Since it is additive manufacturing, there is no need to remove leftover material , which improves the utilization rate of materials.

6. 3D printing does not require a centralized and fixed manufacturing workshop, and has the characteristics of distributed production.

7. It is suitable for customized design and production of single piece or small batch.

Disadvantages:

1. Material limitations. Although a wide variety of materials have been developed for printing, the available materials are still very limited compared to traditional manufacturing processes.

2. Low practicality. Due to the limitations of material properties and processing technology, the products are deficient in strength, stiffness, toughness, heat resistance, fatigue resistance and chemical properties. 3D printing is more suitable for validating design prototypes and less suitable for actual mass production products. Since 3D printing adopts the additive manufacturing process of "layered manufacturing, layer-by-layer superposition", no matter how close the combination of layers is, it cannot be compared with the parts cast as a whole by traditional molds, because the microstructure and the structure of the part material determine the performance of the part.

3. The precision of the product is limited. Due to the limitation of materials and stacking process, the precision of the product is difficult to reach the precision of machining.

4. The printing speed is still very slow. For a single product, the overall cycle of 3D printing from R&D, design to production is greatly shortened, but for mass production, the use of traditional mold manufacturing methods has obvious advantages in the speed of production.

5, The product is difficult to do post-processing. 3D printed products are difficult to carry out post-processing, such as polishing, oil spraying, etc.

As a single-piece and small-batch application, 3D printing is more and more widely used. The important application of 3D printing in industrial manufacturing is to make prototypes to verify the design when some products do not need high performance requirements.

Mastars' industrial prototype service, with products and services that exceed customer expectations, is well-known in Europe and the United States, and has a high customer reputation. The industry covers a wide range of fields, including automobiles, motorcycles, health care, outdoor sports, home appliances, household goods, 3C Electronics, agriculture, stage lighting and outdoor sports, etc.

Mastars has a professional team of engineers and service teams, adhering to the spirit of craftsman in industry, to provide comprehensive solutions for your product development and production. At the same time, our company meets the customized order requirements of customers in various industries with the tenet of multi-variety, small batch and fast delivery.

So if you have any needs for prototype parts or mass production, please feel free to contact us, we are the most suitable partner that you have been looking for.

Mastars Industries CO., LTD

Website: www.mastars.com

• Email: marketing@mastars.com

• Tel: +86 755-88210689

• Fax: +86 755-8821 0685

• Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China(518104)