Mastars often selects aluminum alloy as the material in the manufacture of rapid prototypings, molds, etc., and then completes it through CNC machining, casting, extrusion, die casting and other processes.

Aluminum is one of the most commonly used machining materials because of its excellent mechanical properties, including softness, economy, durability and resistance to corrosion. At the same time, aluminum alloy precision parts and products are very popular because of their light weight and exquisite appearance, and they are more and more widely used in industrial fields and daily necessities. With the continuous advancement of science and technology, people's demand for product diversity is getting stronger and stronger. Therefore, the process requirements of aluminum alloy products are getting higher and higher, and the market demand is also greater and greater.

Aluminum parts are generally cheaper because it can be machined in a short time compared to other metals such as steel, and no additional finishes are required. Small amounts of zinc, magnesium, copper, and other materials are typically added to increase strength, since pure aluminum metal is usually very soft. When exposed to the atmosphere, aluminum parts form a thin protective layer that makes them resistant to corrosion and reduces the chance of rusting on their surfaces. It is resistant to chemicals, easy to process, and has great strength relative to its weight.

Compared with other metal materials, aluminum alloy has lower hardness and good cutting performance. The material nature of aluminum determines that it is easy to process and parts can be easily manufactured by stamping, bending and drilling. You can make parts of various shapes according to your needs. Aluminum is much easier to process than steel.

However, due to its low melting point and high ductility, it is easy to fuse on the finished surface or tool, and it is easy to produce burrs and other defects. Generally, the hardness of aluminum plate is below HRC40 degrees, of course, heat-treated aluminum alloy or die-cast aluminum alloy also has higher hardness. Therefore, in the case of machining aluminum alloys, the load on the tool is small. In addition, the aluminum alloy has excellent thermal conductivity, so the cutting temperature of aluminum alloy milling is low, which can increase the milling speed.

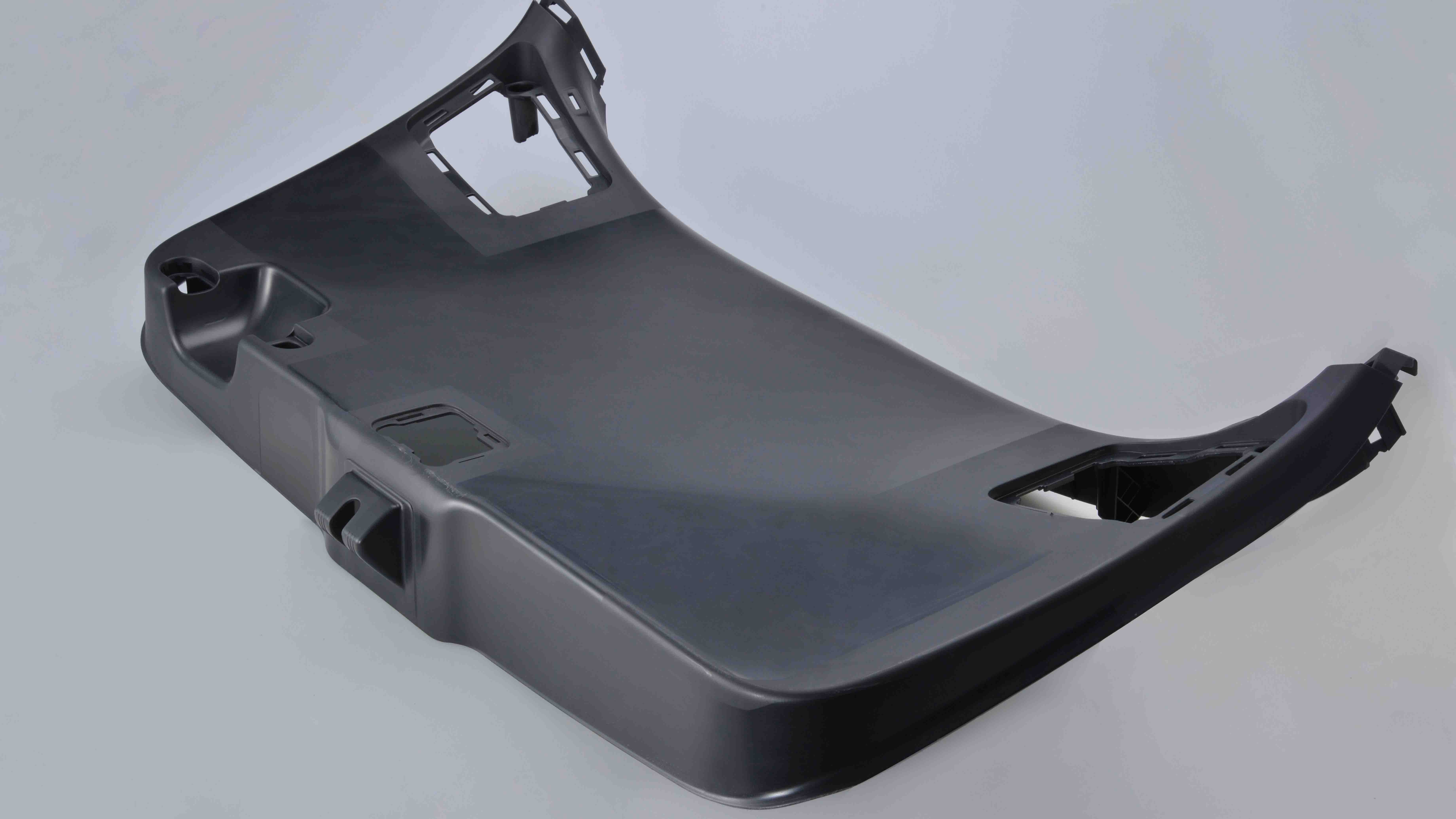

One of the advantages of using a CNC machining process to make aluminum parts is that they can be easily bent. Unlike steel, aluminum materials can be easily turned during machining and can be appropriately molded using a variety of methods. It is best to achieve various shapes of aluminum parts by CNC pressing and machining.

Aluminum is resistant to low temperature. We all know how fragile steel can be, especially in welded sections or in low temperature environments. Compared to other steel materials, aluminum materials can be easily processed at low temperatures.

Aluminum can be customized according to customer's requirements after finishing. Some complex shapes can be processed, and various colors can be plated according to customer's requirements.