Automation in CAD/CAM is transforming CNC machining by improving efficiency, accuracy, and reducing costs. Here's what this means for manufacturers:

For industries like automotive and medical devices, these advancements ensure high-quality output, quicker production, and better resource management. Australian manufacturers, in particular, benefit from reduced material costs and staying competitive in global markets.

Automated toolpath generation takes the guesswork out of CNC programming by instantly calculating the best toolpaths. For systems like Siemens NX CAM at GROB, this can reduce programming time by around 30%.

Here’s how it works: the software analyses the geometry of the part and automatically determines the ideal cutting strategies, feed rates, and spindle speeds. This not only saves time but also reduces the chance of human error, ensuring consistently precise toolpaths. Even for intricate designs that would usually demand hours of manual programming, automation handles the task with ease.

And it doesn’t stop there - this streamlined programming process sets the stage for even greater efficiency gains through digital simulation.

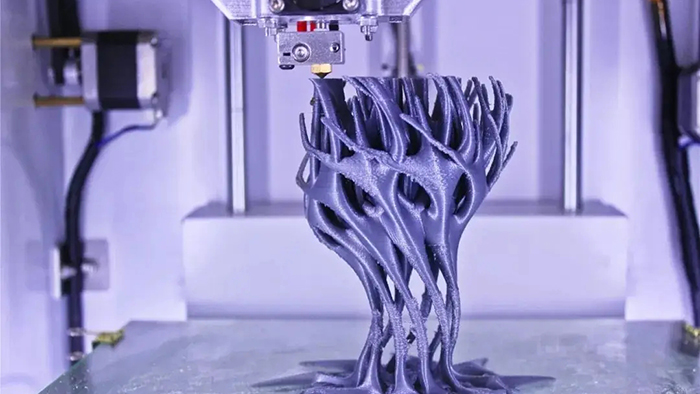

Simulation tools act as a virtual test run, helping manufacturers spot and fix issues before they reach the shop floor. Problems like tool collisions, inefficient cutting paths, or programming mistakes can be identified and resolved early on.

Take D'ANDREA, for example. Using Siemens' integrated CAM solutions, they managed to cut programming times in half and almost completely eliminate material waste through digital twin validation. By predicting potential issues and visualising machine movements, simulations help prevent costly stoppages and scrap material.

This proactive approach keeps production lines running smoothly, with fewer interruptions and wasted resources. The result? A faster, more reliable manufacturing process.

When you combine quicker programming with fewer delays, the outcome is shorter production lead times. This is a game-changer for Australian manufacturers working under tight deadlines.

Automated toolpath generation and simulation don’t just enhance efficiency - they also highlight the broader benefits of CAD/CAM automation in today’s CNC machining landscape.

"By running virtual simulations, manufacturers can identify potential issues, such as collisions or inefficiencies, and refine the toolpaths or manufacturing strategies accordingly. This simulation-driven approach minimises material wastage, reduces production downtime, and optimises overall manufacturing operations."

– Fadal

For businesses juggling global supply chains and strict delivery schedules, these efficiency improvements mean happier customers, more projects, and no need to expand floor space or invest in additional equipment. It’s a win-win for productivity and profitability.

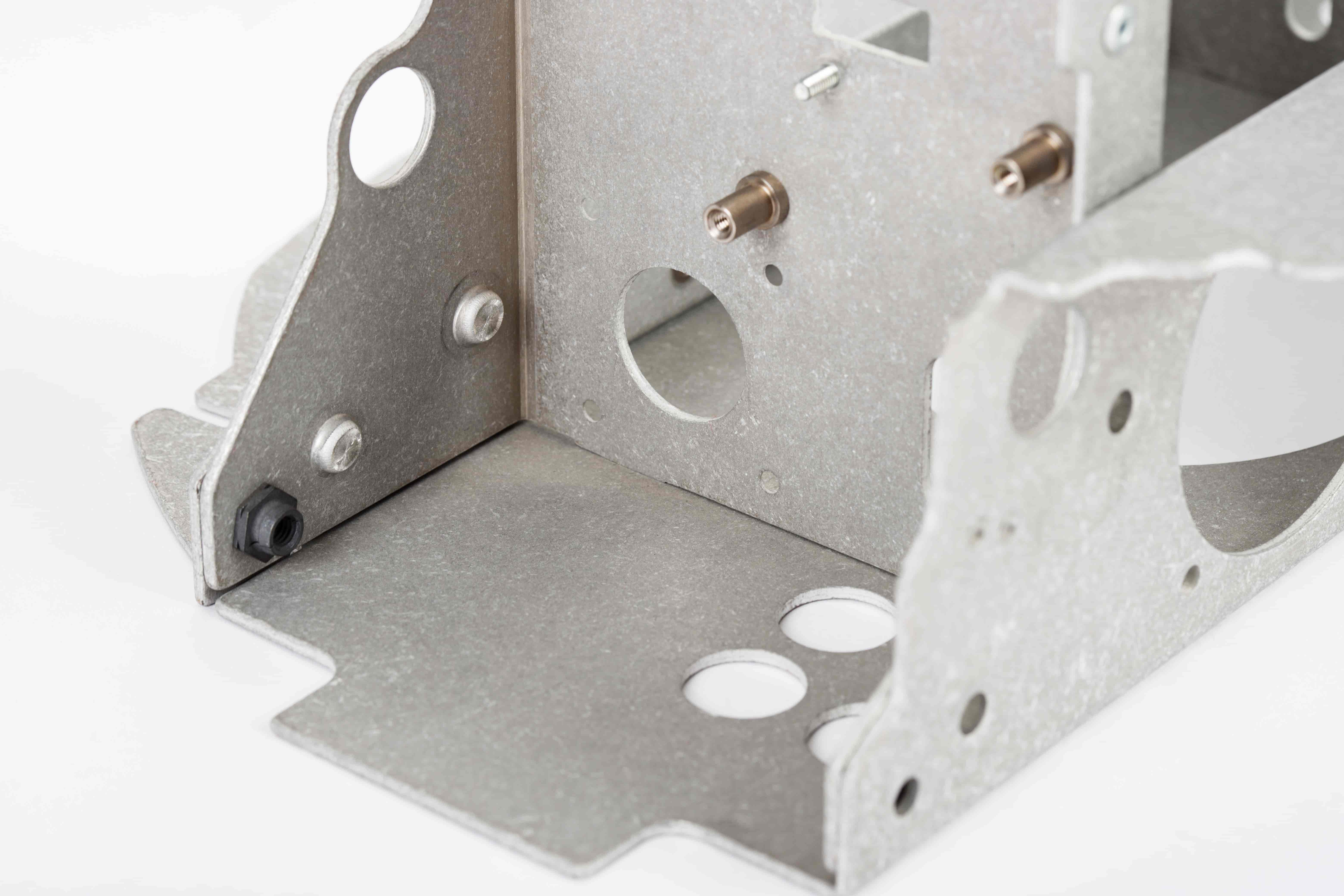

Automated workflows in CNC machining don’t just boost efficiency - they also elevate precision and repeatability. By converting designs directly into machine code through automated CAD/CAM systems, the risk of human error from manual programming is significantly reduced. Instead of relying on manual judgment, these systems use precise mathematical calculations to guide the process.

This means exact coordinates, feed rates, and cutting depths are determined directly from the digital design. The result? A machined output that closely aligns with the original design intent. Errors like missed dimensions, transcription mistakes, or poor tool choices are minimised, ensuring the final product meets expectations.

Another major advantage is consistency. Automated systems use optimised cutting parameters uniformly, whether you're machining the first part or the hundredth. This level of repeatability is difficult to achieve with manual programming.

When it comes to intricate designs - like curved surfaces, angled features, or compound geometries - automation shines. Automated CAD/CAM systems manage the complex calculations required for multi-axis machining without the risk of human oversight or fatigue. They precisely coordinate multiple axes to handle these challenges with ease.

These systems also account for factors like tool deflection, calculate smooth lead-in and lead-out moves, and maintain optimal cutting conditions. This attention to detail ensures that even highly complex geometries are machined to meet demanding quality standards.

Surface finishes on challenging parts also benefit from automation. By fine-tuning stepover distances and balancing cutting loads, the software delivers uniform surface quality across varying geometries and machining operations. This consistency helps manufacturers meet even the most stringent tolerances.

Modern CAD/CAM software includes powerful simulation tools that allow manufacturers to confidently achieve extremely tight tolerances. These simulations can predict how factors like cutting forces, tool deflection, and heat will affect the final dimensions - before any machining begins.

By modelling the entire machining process, including tool wear and thermal effects, these tools help identify potential deformations early on. This ensures that tight tolerances are maintained throughout production.

Additionally, automated systems monitor tool wear and schedule replacements when needed. This proactive approach prevents dimensional drift over time, ensuring consistent accuracy across production runs and helping manufacturers meet global quality standards.

CAD/CAM automation isn’t just about improving efficiency and accuracy - it’s also a game-changer when it comes to saving costs and making the most of resources.

Material costs can eat up a big chunk of a manufacturing budget, so finding ways to reduce waste is key. This is where CAD/CAM automation shines, thanks to its advanced simulation tools. These tools let manufacturers virtually test machining operations before any actual cutting takes place.

By simulating the entire machining process, the software can pinpoint potential issues and address them in the digital space. This means fewer errors, less scrapped material, and a lot less waste. On top of that, the software ensures efficient material use by using smart nesting and cutting strategies. This allows manufacturers to extract more parts from each raw material while maintaining high-quality standards. Automated systems also precisely control cutting parameters, avoiding over-machining and dimensional errors, which ties back to earlier efficiency improvements.

One of the standout benefits of CAD/CAM automation is how much it reduces labour-intensive tasks, allowing skilled workers to focus on more valuable activities.

For instance, automated toolpath generation takes care of what used to be a time-consuming manual process. The software selects the right cutting tools, calculates optimal speeds and feeds, and creates efficient machining sequences - all without human intervention. Setup times are also slashed with features like automated work holding and fixture planning. The software even suggests effective clamping strategies and supports fixture design, which speeds up the entire process.

On top of that, user-friendly interfaces mean operators can get up to speed quickly, cutting down on training time and costs.

It’s not just labour and materials that benefit - equipment gets a boost too. Optimised toolpaths create smoother, more continuous cutting motions, which put less stress on machinery and help it last longer.

These intelligent algorithms distribute cutting loads evenly, ensuring consistent material engagement and reducing wear on specific components. Machine spindles and drive systems also benefit from smoother operations, as the software uses gradual acceleration and deceleration curves to minimise abrupt starts and stops. This reduces vibration, bearing wear, and the need for frequent maintenance.

Adaptive strategies add an extra layer of protection. If the system detects increased cutting forces or vibrations, it can adjust feed rates or tweak toolpaths to maintain ideal conditions. The result? Lower maintenance costs, less downtime, and longer intervals between equipment replacements.

Modern CAD/CAM software is transforming CNC machining with advanced automation tools that cut down manual programming and simplify operations. By introducing features like machining wizards and efficient programming for high-mix, low-volume production, these systems are helping industries achieve greater precision and efficiency.

Machining wizards are a game-changer. They automatically analyse part geometry, choose the right tools, and create optimised toolpaths. This automation means manufacturers can handle everything from basic drilling to complex multi-axis milling with far less manual input, saving time and reducing errors.

For operations that deal with frequent job changes, centralised CNC machine programming is a big advantage. Instead of programming directly on a machine's control panel, operators can create and modify programs on a computer. This method significantly cuts down setup and changeover times, making it ideal for high-mix, low-volume production environments where flexibility is key.

Mastars has embraced advanced CAD/CAM automation to offer rapid and cost-efficient CNC machining solutions. By combining automated programming and rapid prototyping, they cater to industries like automotive, medical devices, and household appliances. Their approach ensures manufacturing strategies are tailored to specific part requirements and production volumes, delivering exceptional results while meeting tight tolerances.

CAD/CAM automation is reshaping CNC machining, offering measurable improvements in efficiency, precision, and cost savings. Key features like automated toolpath generation, simulation tools, and machining wizards have become indispensable for staying competitive.

By automating programming tasks, manufacturers can significantly reduce setup times, while simulation tools help minimise downtime. These advancements directly shorten production timelines and increase throughput, a crucial advantage in Australia's fast-moving manufacturing sector.

Automated workflows also ensure consistent precision and repeatability, even for intricate geometries. This is particularly valuable in industries like automotive and medical devices, where tight tolerances are non-negotiable.

Moreover, optimised toolpaths play a pivotal role in reducing material waste, prolonging equipment lifespan, and decreasing reliance on highly specialised programming expertise. These factors combine to enhance profitability and operational efficiency for Australian manufacturers.

Companies like Mastars showcase the benefits of CAD/CAM automation, leveraging it for rapid prototyping and delivering solutions across industries such as automotive, medical, and household appliances.

For manufacturers in Australia, adopting CAD/CAM automation isn’t just an option - it’s a necessity to thrive in an increasingly automated and competitive environment.

Automation within CAD/CAM software has transformed the way programming tasks are handled, slashing programming time by simplifying repetitive actions and automating intricate processes. Tools like automatic toolpath generation, refined machining strategies, and built-in feature recognition enable programmers to dedicate their energy to more complex and rewarding tasks, rather than getting bogged down with manual setups.

By cutting down on manual input and boosting overall efficiency, automation can reduce programming efforts by as much as 30% or even more. This not only speeds up workflows but also enhances consistency and precision in CNC machining projects, delivering reliable results every time.

Simulations play a crucial role in CNC machining, offering a way to refine accuracy and streamline operations. By running machining programs in a virtual setup, potential errors can be spotted and addressed before actual production starts. This proactive approach helps prevent costly mistakes and downtime on the shop floor.

Beyond error prevention, simulations are invaluable for fine-tuning tool paths. They ensure cuts are precise and materials are used efficiently, which not only reduces waste but also lowers costs. This approach supports a more resource-conscious manufacturing process. Incorporating simulations into daily workflows allows manufacturers to deliver high-quality results while staying focused on efficiency and reducing material usage.

Australian manufacturers can take advantage of CAD/CAM automation to boost efficiency, accuracy, and cost savings in their production processes. By automating workflows, businesses can cut down on material waste, shorten production times, and adapt swiftly to changing market demands. This becomes especially useful in tackling challenges like high operating costs and the need for smaller, more tailored production runs.

The integration of CAD/CAM systems not only enhances product quality but also supports mass customisation, allowing Australian manufacturers to cater to a wide range of global market requirements. These technological advancements simplify the shift from design to production, helping businesses stay competitive internationally while delivering cost-efficient and high-quality products.