For

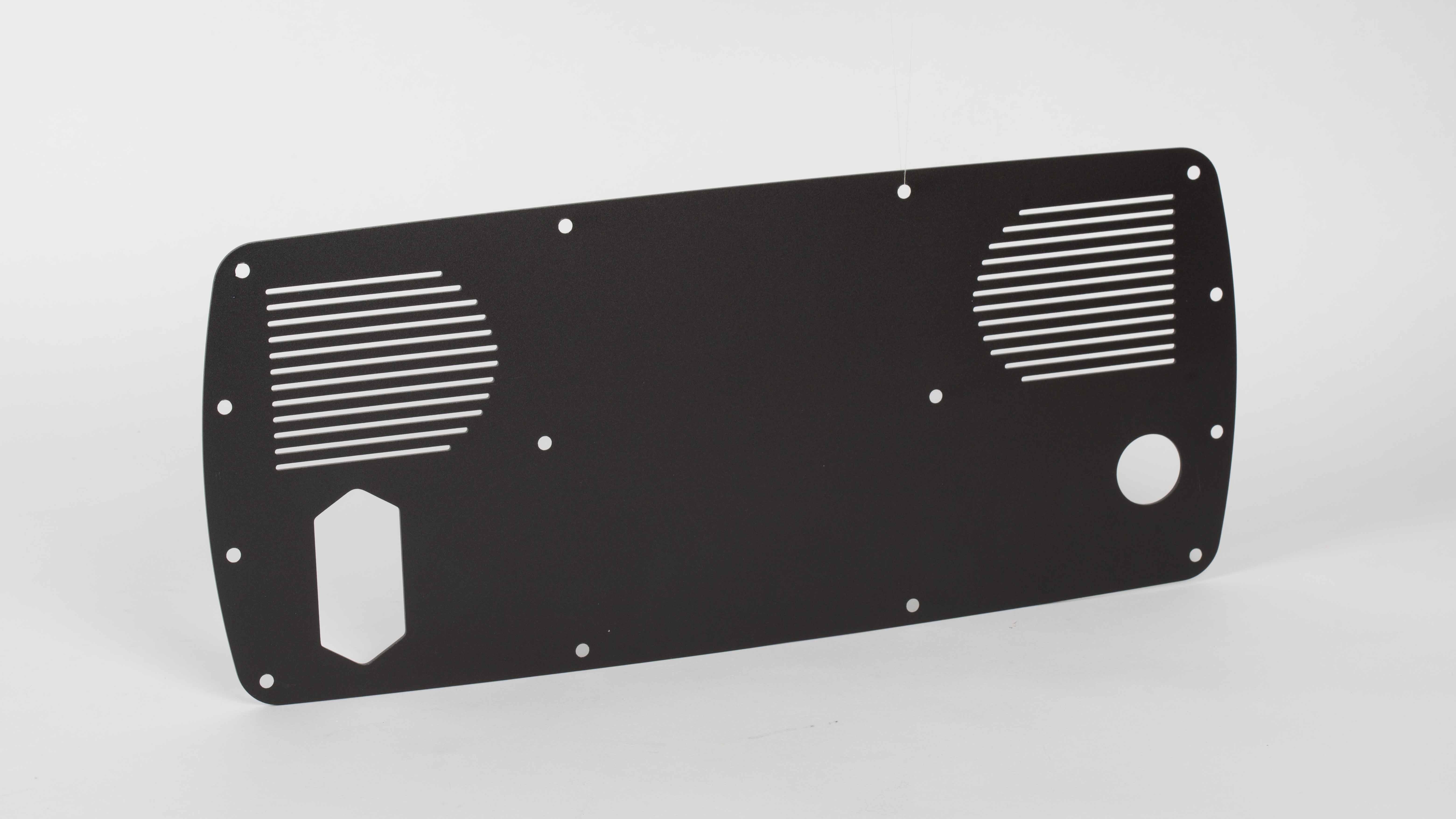

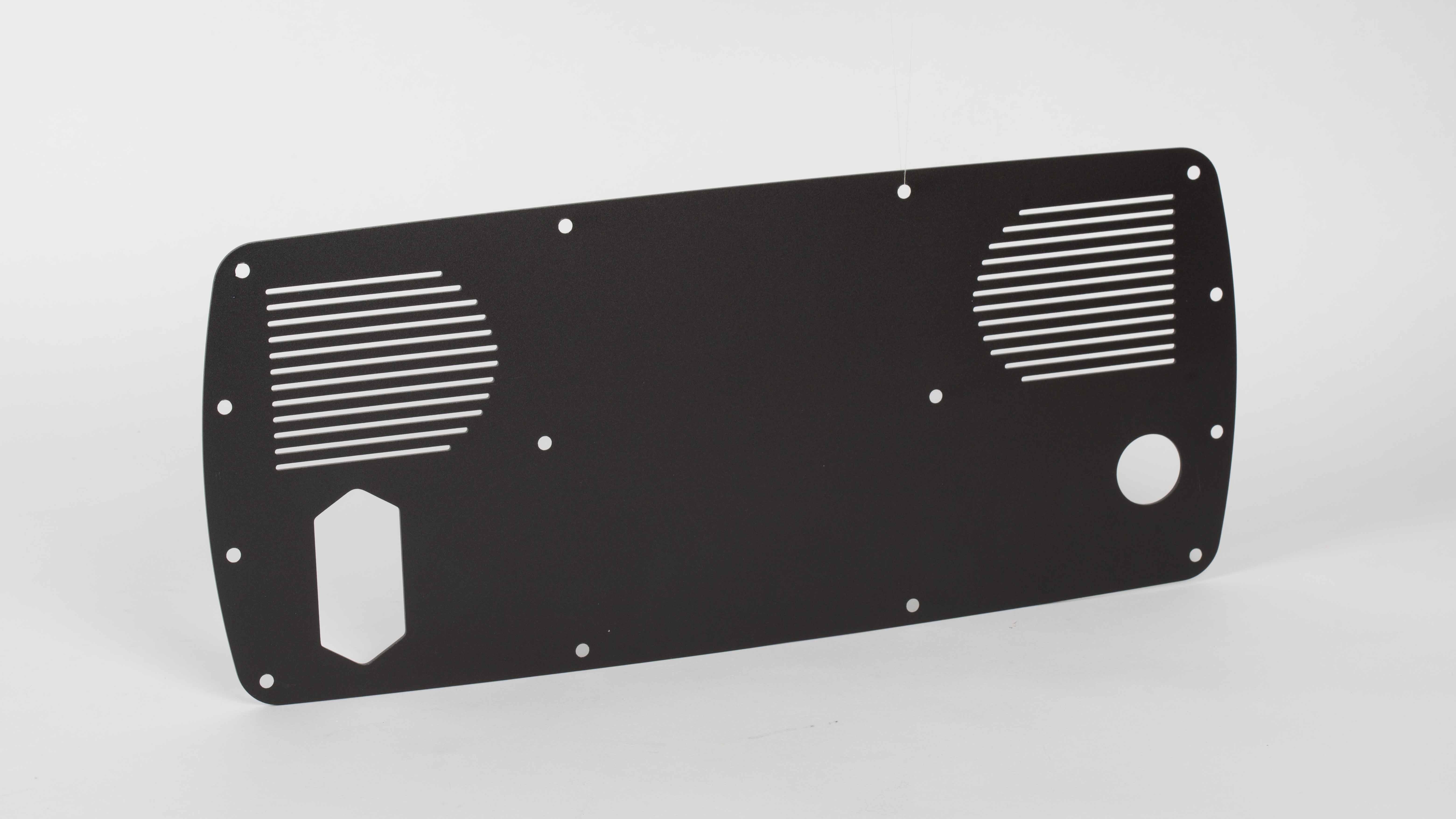

sheet metal products, most materials except stainless steel require anti-corrosion, anti-rust and anti-oxidation.

Mastars is a

metal prototype maker who is very familiar with the properties of materials, can produce the best products, and provides

rapid cnc services,

rapid sheet metal prototyping.

1. Materials commonly used in sheet metal processing industry include sus stainless steel, SECC electrolytic plate, SGCC galvanized plate, SPCC cold rolled plate, SPHC hot rolled plate, Al aluminum plate and spte sheet. Except stainless steel, other materials generally need rust prevention and oxidation prevention.

2. Anti corrosion of SUS stainless steel: passivation treatment

3. SECC electrolytic plate, SGCC galvanized plate and spte tinplate are not easy to rust because of the coating on the surface of the material itself, but the cutting surface is easy to rust. Anti corrosion method: a. the cutting surface is coated with silver paint; B. The cutting surface shall be coated with anti rust agent; C. The whole product is washed with rust inhibitor. (antirust agent is a fast volatile antirust chemical reagent, which will not damage the appearance and performance of the product)

4. Anti corrosion method of SPCC cold rolled plate and SPHC hot rolled plate: A. electroplating; B. Baking paint; C. Plastic spraying

5. Anti corrosion method of Al aluminum plate: A. anodizing; B. Baking paint; C. Plastic spraying

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China