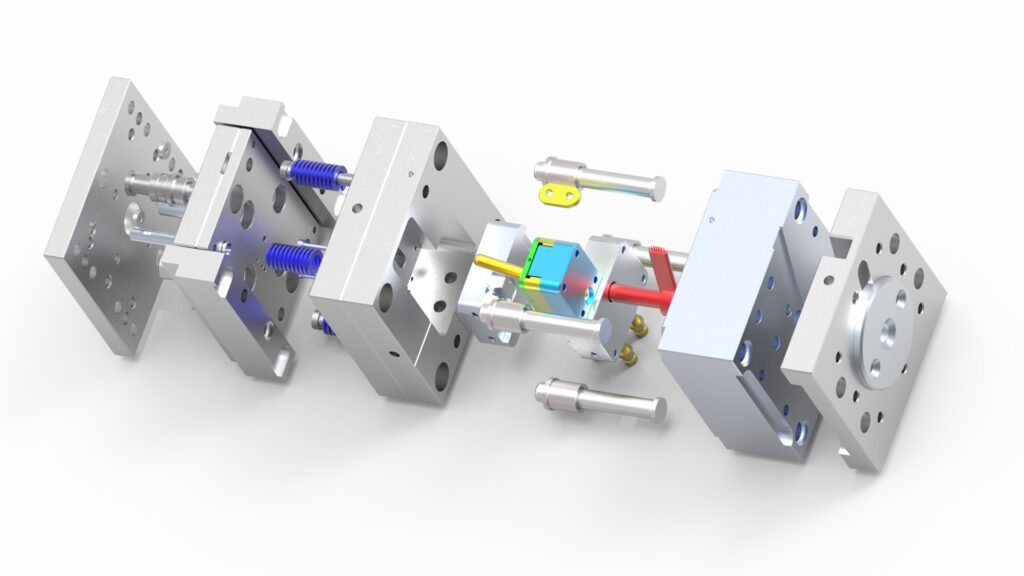

1. The injection pressure of the die-casting mold is large, so the template is required to be relatively thick to prevent deformation

2. The gate of the die-casting mold is different from that of the injection mold, and a splitter cone is needed to decompose the high pressure of the material flow

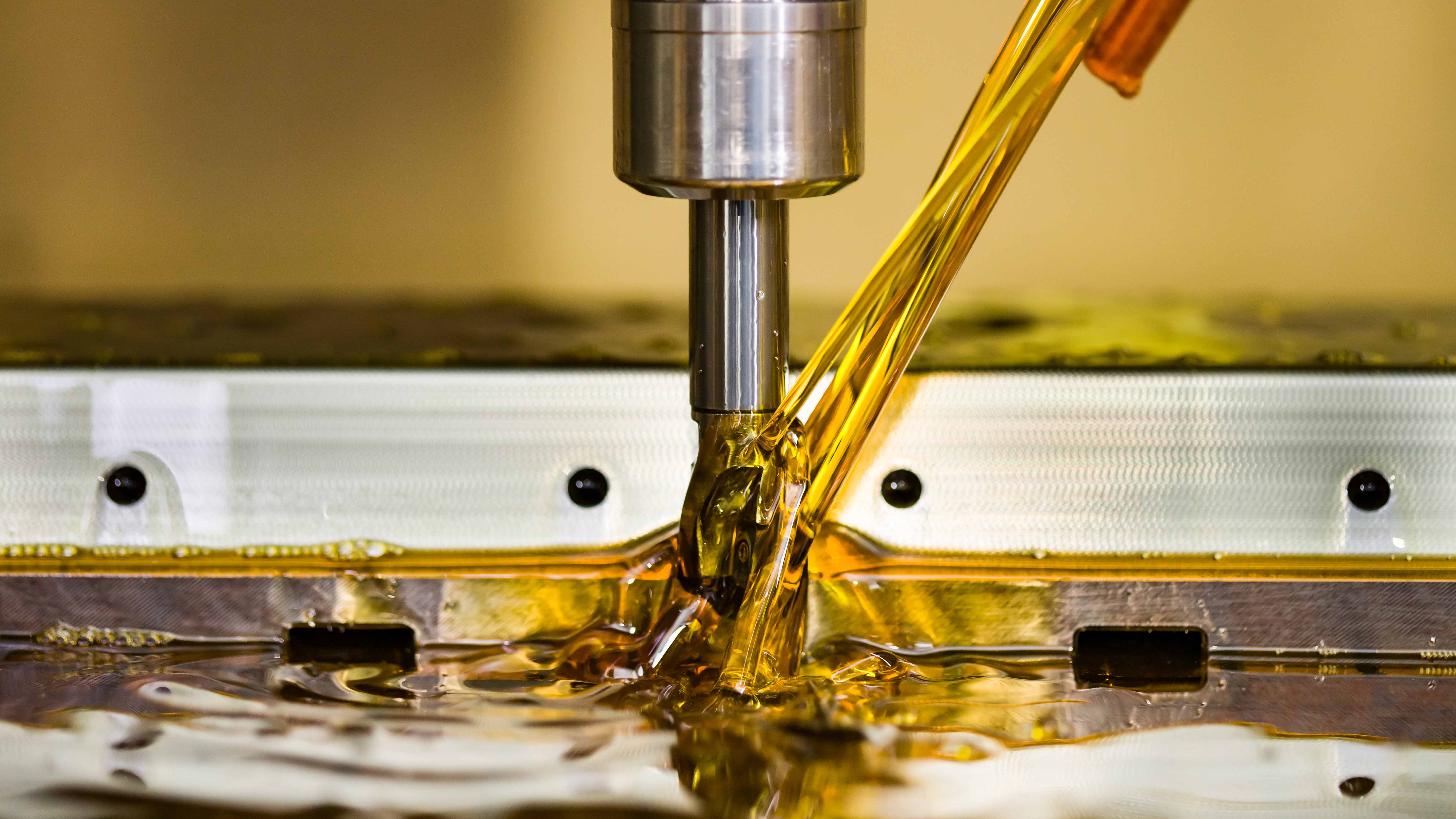

3. The die core of the die-casting die does not need quenching, because the temperature in the die cavity during die-casting exceeds 700 ℃ So every molding

Equivalent to quenching once The mold cavity will become harder and harder The general injection mold should be quenched to above hrc52

4. Generally, the die-casting mold cavity should be nitrided to prevent the alloy from sticking to the mold cavity

5. Generally, the corrosion of die-casting mold is relatively large, and the outer surface is generally blued

6. Compared with the injection mold, the fitting clearance of the movable fitting part of the die-casting mold (such as the core pulling slider) is larger,

Because the high temperature of the die casting process will cause thermal expansion If the gap is too small, the die will be stuckHigh temperature and high pressure material flow flying out of the parting surface will be very dangerous

8. Generally, the injection mold can be vented by ejector pin, parting surface, etc., and the die-casting mold must be provided with an exhaust slot and a slag collecting bag (collecting the cold material head);

9. The molding is inconsistent, the injection speed of the die-casting mold is fast, and the injection pressure of a section is high Plastic molds are usually injected in several sections to maintain pressure

10. The die-casting mold is two plate mold (I haven't seen three plate die-casting mold for the time being), and the mold is opened at one time. The product structure of different plastic molds is different

Plate mold is common, and the number and sequence of mold opening match with the mold structure Our die-casting mold usually does not use square thimble and cylinder,