Contents:

Mastars

manufacture of rapid prototyping

molds

CNC machining, extrusion, die casting

Automotive

medical and personal care, medical consumables

customized manufacturing services

high precision parts

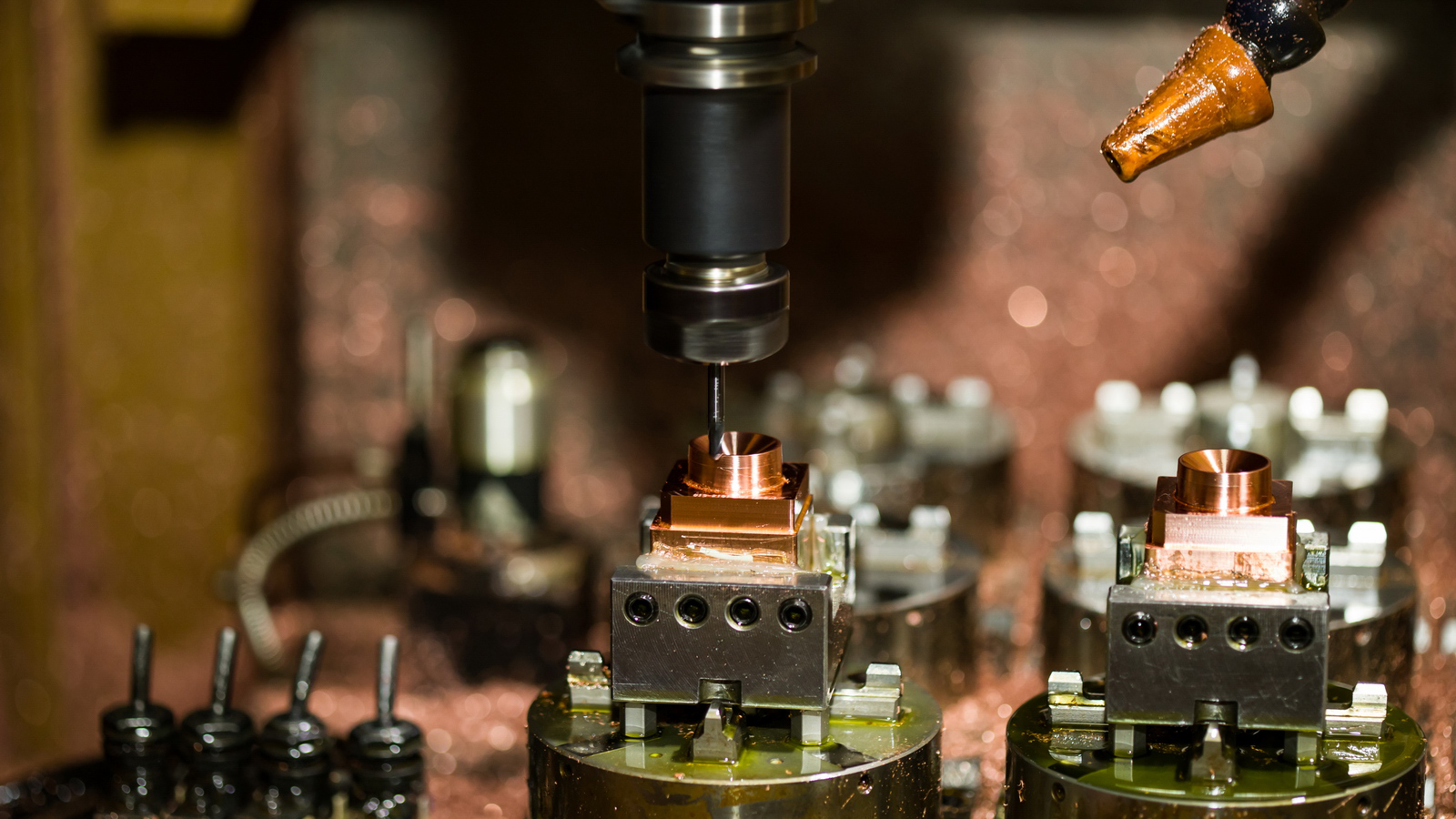

Mastars often selects aluminum alloy as the material in the

manufacture of rapid prototyping,

molds, etc., and then completes it through

CNC machining, casting, extrusion, die casting and other processes.

What is the basic aluminum anodizing process?

Anodizing is an electrochemical process for the passivation of aluminum. This process is difficult to compare with any other surface treatment, as aluminum plays an active role during anodizing. As part of this process, a thin layer of aluminum oxidation is created, fully integrated with the outer surface of the profiles, thus offering remarkable features, such as: aesthetics, shade stability, durability, ease of maintenance, health & safety.

Anodizing: mainly the anodizing of aluminum, which uses the principle of electrochemistry to form a dense oxide film on the surface of aluminum. Anodizing is a kind of metal (generally aluminum plate and aluminum alloy) surface treatment process. It refers to the process of forming oxide film on the surface of materials through anodic current under electrolyte solution, which is called surface anodic oxidation.

Characteristics of anodic oxidation process

Anodizing can improve the corrosion resistance, surface hardness and wear resistance of aluminum alloy products, and has good decoration after coloring treatment. The anodic oxidation process mainly includes degreasing → etching → neutralization → anodic oxidation → coloring → hole sealing.

Why should aluminum plate be anodized?

The reason why aluminum plate should be anodized is to overcome the defects of aluminum plate surface hardness, wear resistance and easy oxidation, expand the application scope and prolong the service life. You know, in the air, the aluminum plate will oxidize after long-term use. Although the natural oxide layer on the surface has a certain passivation effect, the oxide film will fall off, be corroded and the aluminum plate will change color after long-term overexposure.

Advantages of anodized aluminum plate

As one of the decorative materials of aluminum plate, the reason why anodized aluminum plate can become an outstanding representative is closely related to its advantages and characteristics.

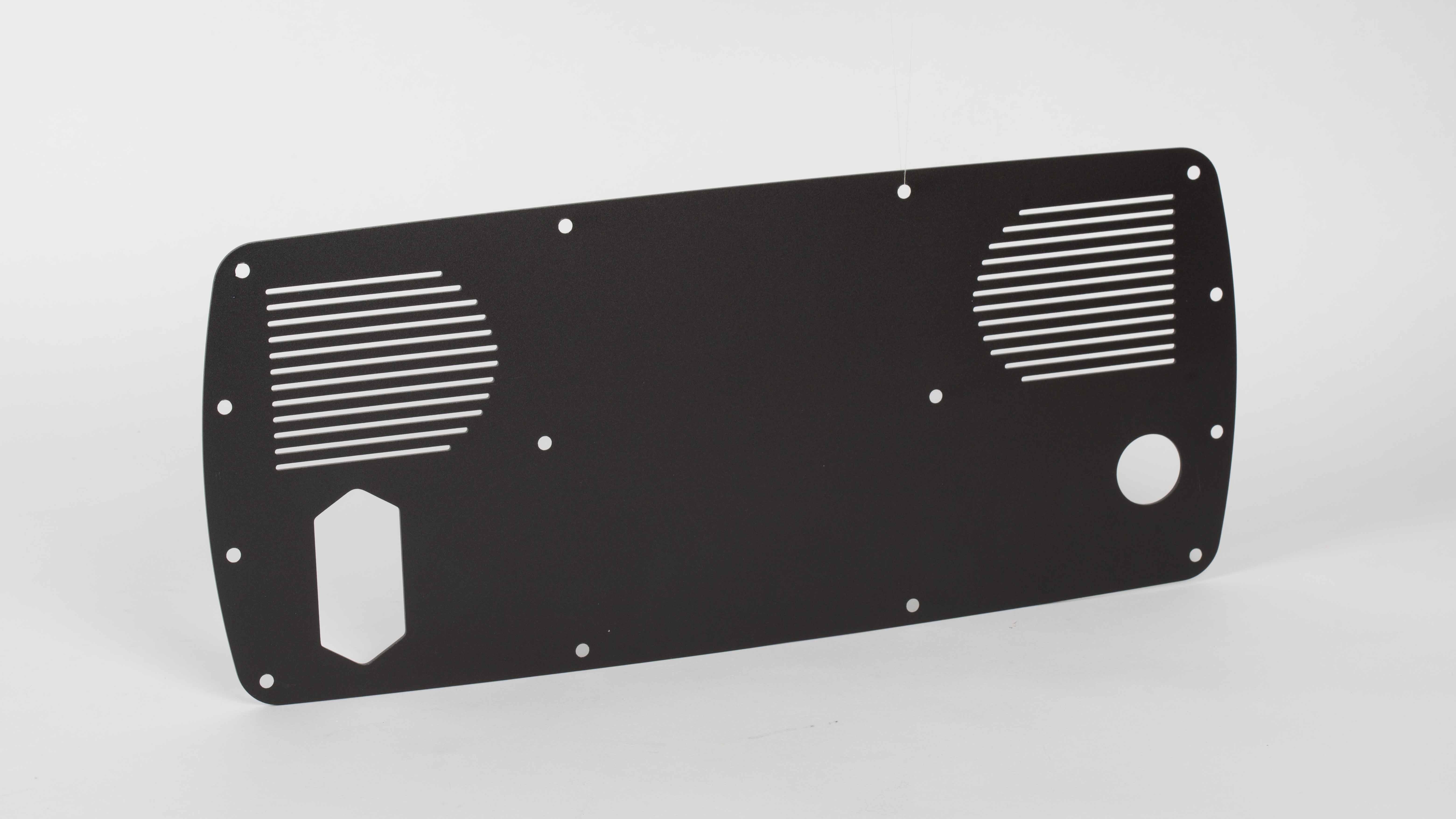

1. Excellent processing performance: anodized aluminum plate has strong decorative performance, and the hardness of aluminum plate is moderate, so it can be easily bent and formed without other complex treatment processes. Thus, the production cycle and product cost are reduced.

2. Excellent performance: Standard oxide film thickness 3 μ M anodized aluminum plate is applied to indoor decorative panel, household appliance decorative panel, etc., which is not easy to change color and oxidize after long-term use; Thicker oxide film for outdoor decoration 10 μ M above long-term exposure to ultraviolet light, it is not easy to change color.

3. Delicate metal texture: the soft metal texture of anodizing. Compared with ordinary aluminum plate, the aluminum surface has rich colors and realistic colors after many anodizing and coloring treatments.

4. Not easy to scratch: the surface hardness is firm and reliable, difficult to wear, strong scratch resistance, and the scratch resistance grade reaches 3H.

5. Acid and alkali resistance, corrosion resistance: excellent corrosion resistance, free from corrosion and colorless change in salt spray test. It has good acid and alkali resistance and high weather resistance. The product is durable.

Mastars

Mastars is a company that designs, develops and produces precision plastic parts. The products involve in

automotive, communication electronics,

medical and personal care, medical consumables, smart home, semiconductor, new energy and other fields, focusing on the development of smart medical, artificial intelligence, IOT and other fields, providing customers with

customized manufacturing services of

high precision parts.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210689

Fax: +86 755-8821 0685

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China.