Reaction injection molding, referred to as rim, is an industrial molding process. An injection molding method with chemical reaction in the molding process. The raw material used in this method is not polymer, but two or more liquid monomers or prepolymers are added to the mixing head in a certain proportion, mixed evenly under pressure, immediately injected into the closed mold, polymerized and solidified in the mold, and shaped into products.

As for the reaction injection molding (RIM) process, its principle is that a and B raw materials produce polyurethane (PU) or other polymers through thermochemical reaction by mixing in the mixing head and mold cavity.

It is different from the injection molding process as follows:

1. different forming principles

The raw material of injection molding is thermoplastic, which is heated into a molten state through high temperature and cooled and solidified in the mold. It belongs to physical reaction and is reversible; The raw materials of RIM process are thermosetting plastics (such as PU, DCPD, etc.), and the two raw materials are liquid at room temperature without heating and solidified through chemical reaction, which belongs to chemical reaction and irreversible.

2.On the product design structure of molding

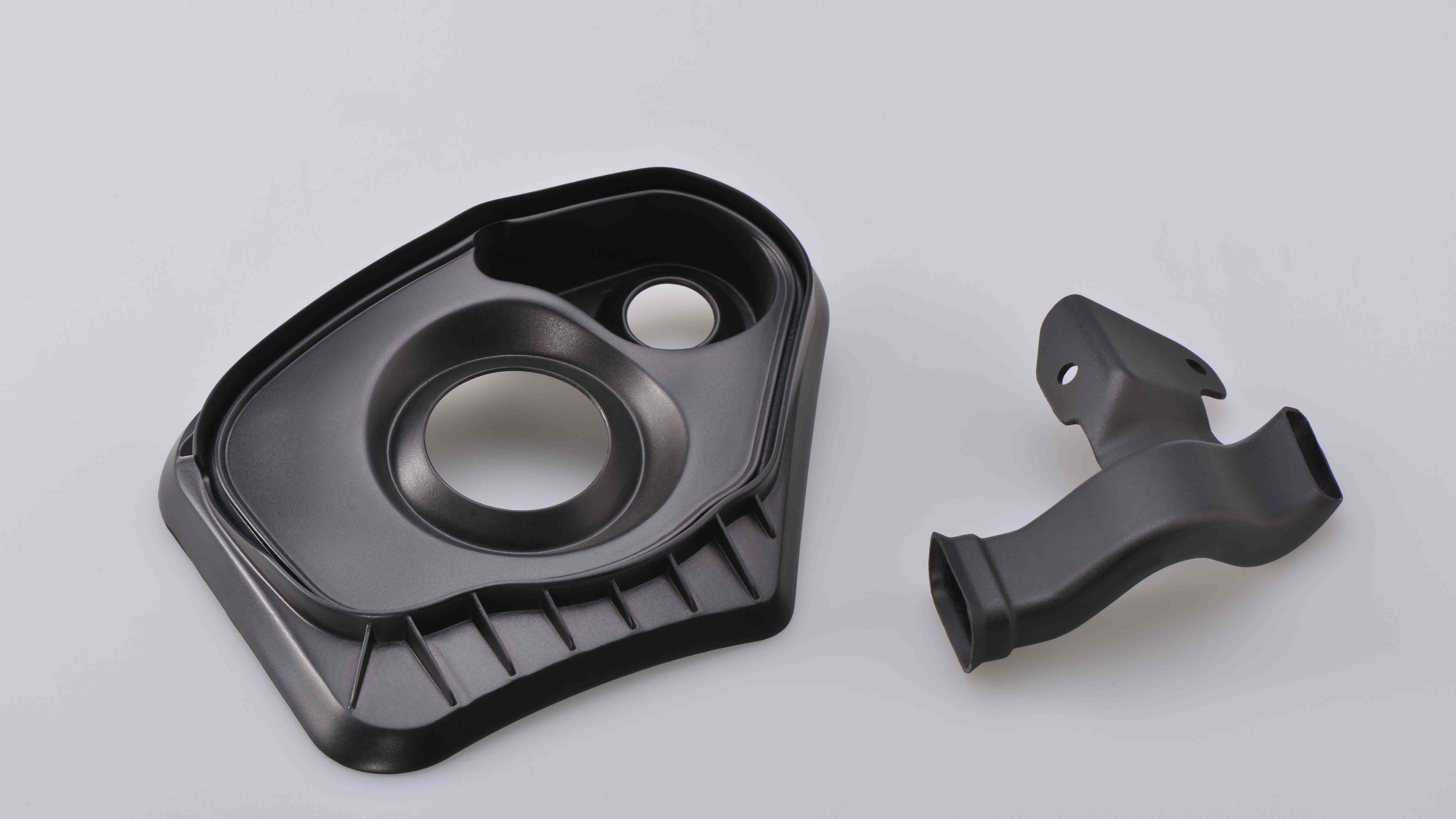

1) Injection molding can form parts with complex and precise structure; Rim process is suitable for forming large shell parts with simple structure, and the size requirements are not very strict;

2) In the design of injection molding products, try to consider the uniform wall thickness, and do not be too thick; Rim process is suitable for forming parts with thick wall thickness (more than 6mm) or different wall thickness. It has a large degree of freedom in design and will not produce internal stress and surface shrinkage marks.

3.in terms of output

1) The injection molding process is suitable for mass production and has high efficiency; Rim process is suitable for small batch production (annual demand is about 50-5000), large and small batch parts production and trial production of parts in R & D stage;

2) In the case of small batch, RIM process has less investment and shorter cycle than injection molding process;

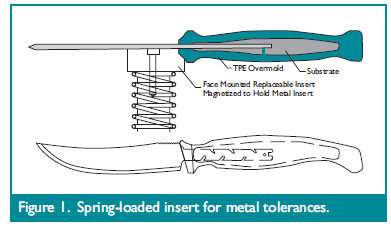

4. Due to the characteristics of raw materials, RIM process can form parts with different density, hardness and elasticity, and the inlay function and effect are good

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210689

Fax: +86 755-8821 0685

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China

Contents

Mastars

vacuum forming

CNC machining

injection molding

prototype manufacturing