1. Executive Summary

Metal Injection Molding (MIM), also known as Powder Injection Molding (PIM), is an advanced

manufacturing process that combines the design flexibility of plastic injection

molding with the material performance of wrought metals. It enables the

high-volume production of complex, high-precision, and high-strength metal

parts. MIM is often described as a "cross-over" technology, bridging

the gap between conventional plastic injection molding and precision investment

casting or machining.

2. Core Principle & Key Characteristics

The fundamental

principle of MIM is to use a feedstock—a

homogeneous mixture of fine metal powder and a thermoplastic binder—which can

be injection molded like plastic. After molding, the binder is removed, and the

remaining "brown" part is sintered at high temperatures to achieve a

near-fully dense metal component.

Key Characteristics:

3. The MIM Process: A Four-Step Workflow

The MIM process

consists of four critical and sequential steps:

Step 1: Feedstock Preparation

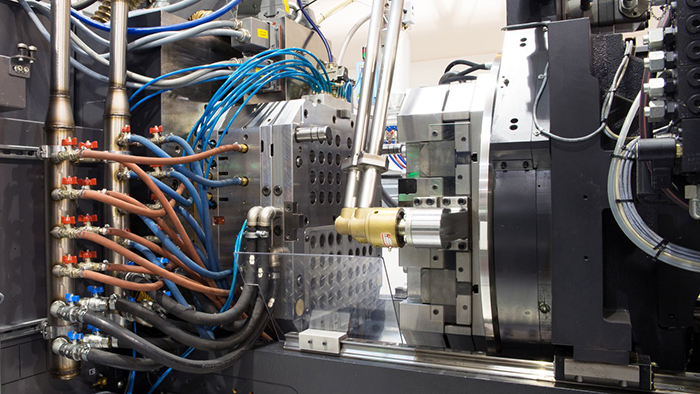

Step 2: Injection Molding

Step 3: Debinding

Step 4: Sintering

4. Key Advantages and Limitations

|

Advantages |

Limitations |

|

Design freedom for complex 3D geometries. |

High initial cost for tooling and setup. |

|

Excellent mechanical properties (near-wrought

metal). |

Limited to relatively small parts (generally

< 100 grams, though larger parts are possible). |

|

High-volume production efficiency. |

Significant, uniform shrinkage must be

accurately predicted in mold design. |

|

Good dimensional accuracy and surface

finish. |

Material selection is limited to alloys that

are available as fine, spherical powders. |

|

Material versatility (stainless

steels, tool steels, superalloys, titanium, etc.). |

Less economical for low volumes due to high

tooling costs. |

5. Comparison with Other Technologies

|

Feature |

Metal Injection Molding (MIM) |

Investment Casting |

CNC Machining |

|

Complexity |

Excellent (true 3D

complexity, fine details). |

Good (complex but often limited by core

removal). |

Limited by tool access. |

|

Part Size |

Small to medium (typically < 100g). |

Small to very large. |

Virtually unlimited. |

|

Mechanical Properties |

Excellent (near-full

density). |

Good (can have porosity). |

Excellent (wrought material). |

|

Surface Finish |

Very good (Ra 1-2 µin). |

Rough (requires finishing). |

Excellent (machine finished). |

|

Cost Driver |

Low per-part cost at high volumes. |

Moderate tooling, moderate per-part cost. |

High per-part cost (labor, material waste). |

|

Lead Time |

Moderate (weeks for tooling). |

Moderate. |

Fast for prototypes. |

6. Common MIM Materials & Applications

Conclusion

Metal Injection Molding is a powerful and

unique manufacturing technology that excels at producing small, complex,

high-performance metal components in high volumes. While the process involves

significant upfront engineering and tooling investment, it becomes highly

cost-effective for complex parts that would otherwise require extensive and

wasteful machining or multiple assembly operations. It is the ideal solution

when design complexity, material performance, and production volume converge