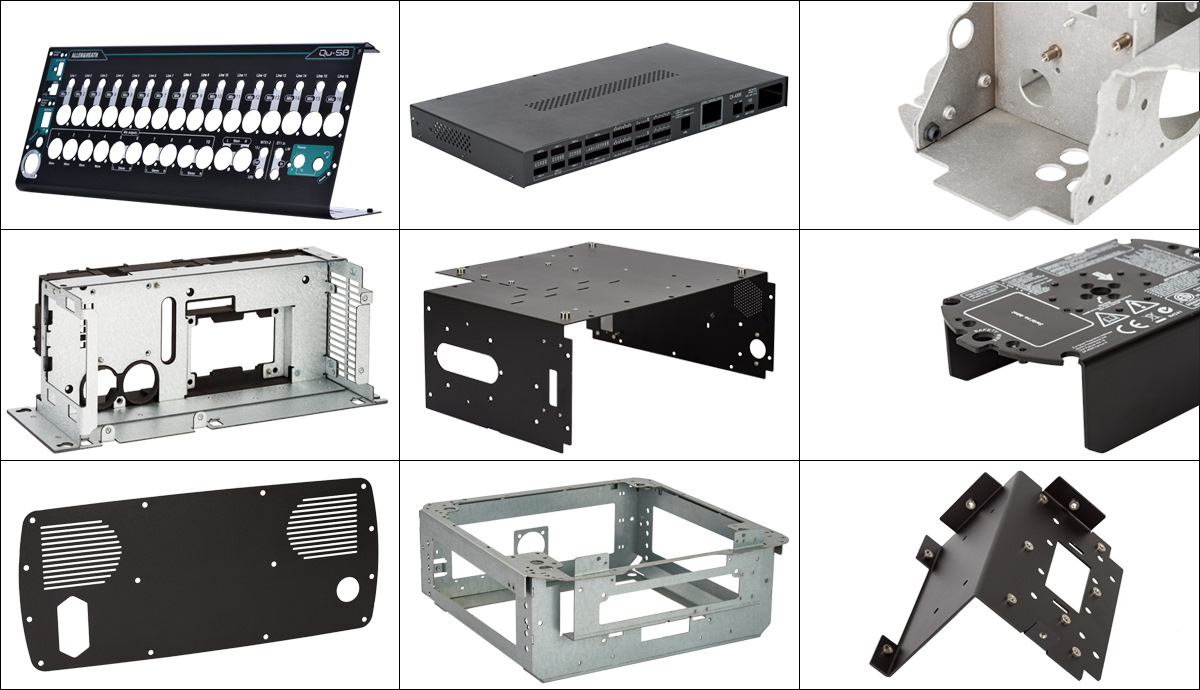

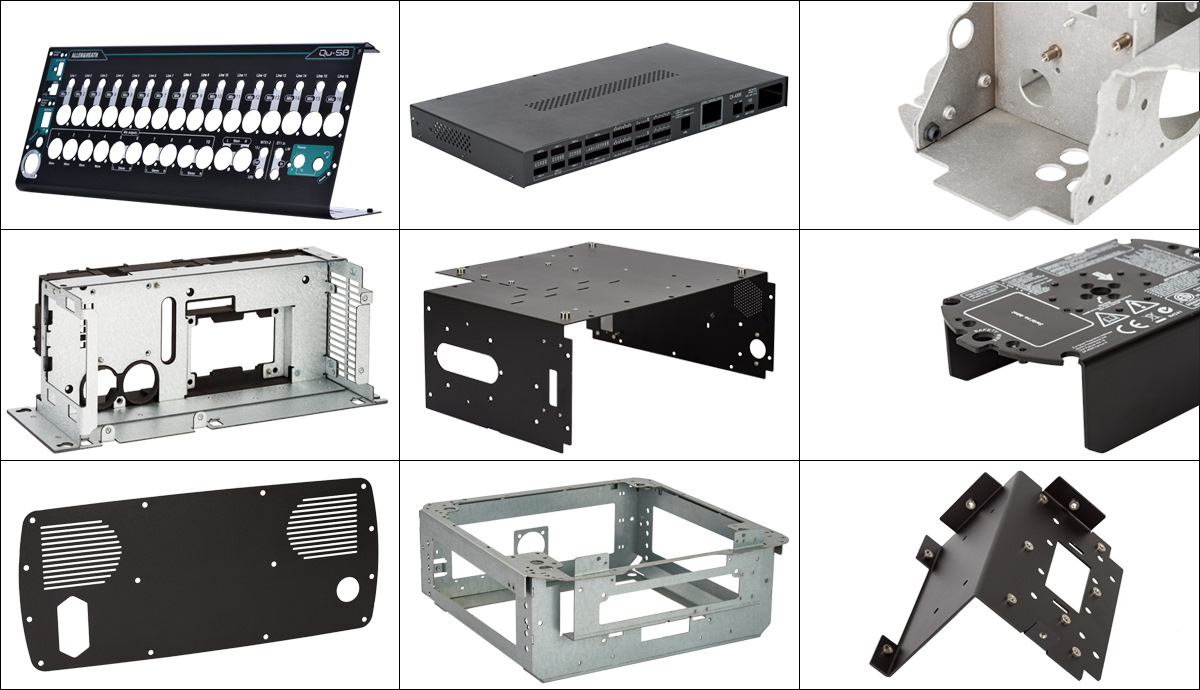

Mastars is ametal prototype maker, engaged in sheet metal processing, precision sheet metal processing, Chinese sheet metal processing, sheet metal chassis processing, sheet metal cabinet processing, communication equipment processing, communication chassis cabinet processing. It can meet customers' needs of high quality, low cost and urgent cycle.

The first process in sheet metal processing is blanking. In large-scale industrial production, the blanking method of sheet metal materials is mainly cut by punch and shear machine, and can also be cut by various high-energy beams. For example, the plate can be cut with laser, electron beam and ion beam, and the incision is neat and beautiful. Combined with numerical control technology, automation can be easily realized with high efficiency.

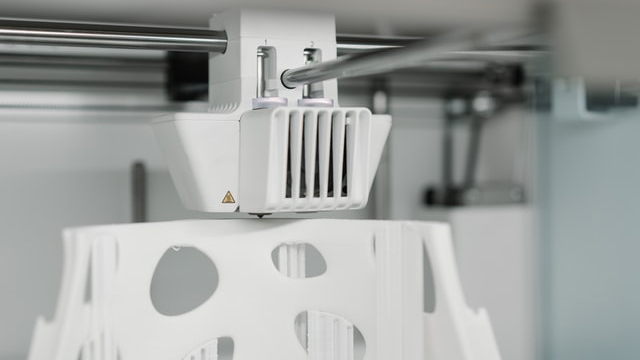

After the current material is completed, the sheet metal processing will enter the second process, namely forming, which mainly includes stretching and bending, in which the corresponding stretching die and bending die need to be used. It is generally stretched on ordinary punch and CNC punch. The bending process can only be carried out on the bending machine or CNC bending machine. CNC bending machine is mainly used in modern industrial production, while manual bending machine is mainly used in single piece and small-scale trial production.

If other auxiliary parts need to be added to the formed workpiece, the sheet metal processing process can also include welding, riveting and other processes. To add auxiliary screws, nuts, studs, etc. to

sheet metal parts., It can be operated by resistance welding, arc welding and other welding methods. When selecting the welding method, it should be noted that the heat input of sheet metal parts should not be too high, otherwise it is easy to deform.

Processing flow

1. Blanking: there are various blanking methods, mainly including the following methods: shearing machine, high-speed punch, CNC machine tool blanking, laser blanking and CNC sawing machine;

2. Milling worker: countersunk, tapping, reaming, rotating hole;

3. Pressing groove: also known as hole pulling and hole turning, that is, add a slightly larger hole on the smaller base hole and then tap;

4. Riveting: the key is riveting nuts, screws, looseness, etc. Operate according to hydraulic press, riveting machine or high-speed punch;

5. Sheet metal bending: sheet metal bending refers to stacking 2D tablet computer parts into 3D parts;

6. Electric welding: welding the distance between the original atomic nucleus and molecular structure and Jingda lattice constant.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China