Copper alloys are a standout choice for pressure die casting, especially in Australia's demanding industries like automotive, mining, and electronics. Their combination of strength, thermal and electrical conductivity, and corrosion resistance makes them ideal for creating durable, high-performance components. While their upfront cost is higher than alternatives like aluminium or zinc, their longer lifespan and reliability often lead to lower overall costs.

Key benefits of copper alloys in pressure die casting:

Mastars, a trusted provider, combines advanced manufacturing techniques with strict quality control to deliver high-quality copper alloy components tailored to Australian industry needs. Their expertise ensures reliable, efficient solutions for complex applications.

Copper alloys deliver the strength and toughness needed to handle Australia's demanding industrial environments. Known for their high tensile strength and resistance to wear, these materials excel in harsh conditions like those found in the mining operations of the Pilbara or the manufacturing facilities in Newcastle.

"Copper alloys exhibit high durability and resistance to wear, making them tough against surfaces that rub or scratch against each other".

Mastars has seen how this durability translates into real savings for Australian manufacturers. Components made from copper alloys last longer than alternatives, cutting down on maintenance and replacement expenses. Plus, they perform reliably under extreme temperatures, making them ideal for high-heat applications - common in many Australian industries. This combination of strength and thermal resilience sets the stage for their impressive conductivity and corrosion resistance.

Copper alloys are well-known for their outstanding heat and electrical conductivity, making them indispensable for applications that require efficient heat dissipation or reliable electrical performance. Mastars taps into these properties to create components that excel in Australia's often challenging climates.

For example, copper's thermal conductivity enhances the performance of heat exchangers in air conditioning systems, while its electrical conductivity ensures connectors maintain efficiency in demanding environments. These conductive properties, paired with mechanical strength, make copper alloys a go-to choice for industries that need materials capable of handling both heat and electricity effectively.

Australia's wide-ranging environments - from salty coastal air to dusty inland regions - demand materials that can endure tough conditions. Copper alloys rise to the challenge with proven corrosion resistance, ensuring equipment longevity even in the harshest settings. This quality is particularly crucial for machinery operating near the coastline, where salt exposure can severely damage other materials.

"Specific copper alloys like aluminium bronze, bronze, and cupronickel are noted for their high strength, corrosion resistance, wear resistance, and fatigue strength".

Mastars often recommends copper alloys for clients dealing with Australia's varied climates. Whether it's Queensland's humid coastal areas or Western Australia's dry mining sites, these alloys maintain their integrity far longer than competing materials. This durability not only reduces replacement costs but also minimises downtime, keeping operations running smoothly.

Copper alloy pressure die casting offers the precision and surface quality that Australian industries demand. Thanks to the alloys' excellent flow characteristics, the die casting process produces components with tight dimensional accuracy and smooth finishes.

This precision has practical benefits: it reduces or even eliminates the need for secondary machining, saving time and money. Industries like healthcare, automotive, and electronics particularly benefit from this accuracy. Whether it's medical devices requiring exact tolerances, automotive parts needing a perfect fit, or electronics housings with strict specifications, copper alloys deliver reliable results.

Mastars ensures that every casting meets Australia's stringent quality standards through rigorous quality control. The smooth surfaces achieved with copper alloy die casting are especially advantageous for decorative components or parts where surface quality impacts performance directly.

In Australia, the automotive industry relies heavily on copper alloy die castings for parts that demand both electrical efficiency and mechanical durability. Components such as electrical connectors, terminals, and wiring harnesses crafted from copper alloys ensure dependable power distribution. This is especially crucial as electric and hybrid vehicles gain traction on Australian roads.

Mastars provides a range of copper alloy components - brake systems, radiators, fuel systems, and hydraulic fittings - designed to withstand Australia's challenging conditions, from searing summer temperatures that exceed 45°C to the corrosive effects of coastal salt exposure. Additionally, bearing bushings and transmission parts benefit from the wear resistance of copper alloys, offering extended lifespans in the dusty and rugged Australian landscape.

These examples highlight how copper alloys combine thermal and mechanical strengths to meet the unique demands of Australia's automotive sector.

The mining industry, a cornerstone of Australia's economy, also depends on copper alloy die castings for their resilience in harsh environments. Components like pump housings, valve bodies, and impellers are essential for handling abrasive slurries and corrosive chemicals in mineral processing.

Mastars supplies copper alloy parts for conveyor systems, crushing equipment, and separation machinery, all vital to operations in Australia’s mining hubs. Their resistance to saltwater corrosion makes them ideal for offshore drilling platforms and desalination equipment, which are often used in coastal mining operations.

In addition, electrical switchgear and control panels in mining rely on copper alloys for their conductivity and durability. These components must perform consistently in conditions with high dust levels, fluctuating temperatures, and exposure to corrosive gases. Given the 24/7 nature of mining operations, the reliability of copper alloys plays a key role in maintaining productivity.

The electronics sector takes advantage of copper alloys for their precision and ability to manage heat effectively. For instance, circuit board components made from these alloys ensure stable electrical conductivity and mechanical integrity, even under thermal stress.

Mastars delivers solutions like integrated heat sinks paired with electromagnetic shielding, ensuring devices operate efficiently in Australia's demanding climate. This is particularly important during the hot summer months when cooling systems face increased strain.

In power distribution, copper alloy die castings are used in switchgear components, transformer parts, and transmission line hardware across Australia's electrical grid. Their combination of conductivity and corrosion resistance ensures reliable electricity delivery over long distances and through varied environmental conditions.

Telecommunications infrastructure also benefits from copper alloy components in antenna systems, cable connectors, and grounding equipment. These materials are designed to maintain electrical performance while resisting corrosion caused by coastal salt air and intense UV exposure.

The medical field leverages copper alloys for their strength, precision, and natural antimicrobial properties. Surgical instruments, diagnostic equipment housings, and other medical device components benefit from these characteristics, helping to reduce infection risks in healthcare environments.

Mastars produces components for X-ray equipment, MRI machines, and other imaging devices, where heat dissipation and electromagnetic shielding are critical. Copper alloys are also used in dental tools, orthodontic devices, prosthetics, and rehabilitation equipment, offering durability and resistance to bodily fluids.

Strict quality standards in the medical sector align with Mastars' manufacturing processes, ensuring compliance with Australia's Therapeutic Goods Administration requirements and international regulations.

Mastars combines Industry 4.0 automation with traditional die casting expertise to produce precise copper alloy components that align with Australian standards. This blend of modern technology and established methods ensures consistent quality and efficient production cycles.

We specialise in creating custom tooling and moulds designed for specific components. Whether it’s intricate electrical connectors for automotive applications or durable pump housings for the mining industry, we focus on delivering exceptional dimensional precision and smooth surface finishes.

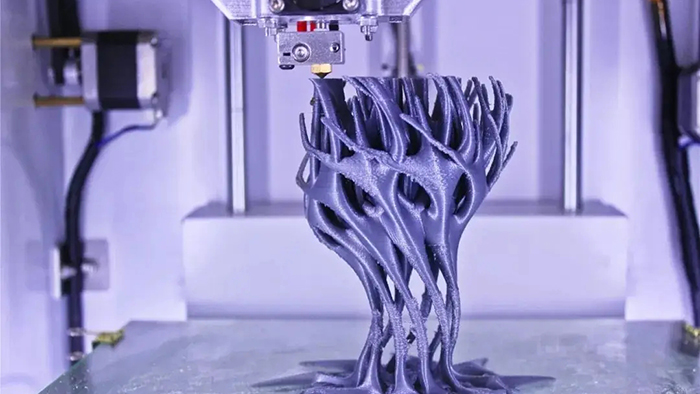

Our automated, computer-controlled systems maintain consistent temperatures, pressures, and cycle times - critical factors when working with copper alloys. Additionally, we offer rapid prototyping through CNC machining, 3D printing, and vacuum casting. This allows Australian clients to validate their designs early in the process, helping to reduce development timelines.

Quality is at the heart of Mastars' operations, with rigorous checks at every stage of production to ensure compliance with Australian standards. Incoming material inspections verify that copper alloy compositions meet required specifications, including tensile strength, conductivity, and corrosion resistance.

During production, real-time monitoring keeps a close eye on key parameters such as melt temperature, injection pressure, and cooling rates. This ensures that variations are minimised, safeguarding the quality of each component. Advanced measurement tools and thorough visual inspections confirm that finished parts meet both technical and aesthetic requirements.

To further guarantee reliability, post-production metallurgical testing validates material properties. This gives our Australian clients confidence that their copper alloy components will perform well, even in challenging conditions.

Mastars provides a seamless manufacturing experience by integrating post-casting services like precision machining and assembly. This approach not only simplifies the supply chain but also reduces logistical complexities, offering a comprehensive solution for our Australian clients.

When it comes to pressure die casting, selecting the right material is a balancing act between performance and cost. For Australian industries, copper alloys often stand apart from alternatives like aluminium, zinc, and magnesium due to their exceptional properties in several key areas.

Mechanical strength is a standout feature of copper alloys. With tensile strengths ranging from 300 to 700 MPa, they outperform aluminium alloys (150-400 MPa) and zinc alloys (200-350 MPa). This makes copper alloys particularly well-suited for applications like mining equipment and automotive components, where durability under extreme stress is non-negotiable.

Corrosion resistance is another area where copper alloys shine, especially in Australia's challenging coastal and mining environments. Copper alloys offer excellent resistance to saltwater and chemical exposure, making them a reliable choice. Aluminium alloys, while resistant to corrosion thanks to their oxide layer, can suffer from galvanic corrosion when in contact with other metals. Zinc alloys, though acceptable for indoor use, fall short in marine or harsh outdoor conditions where copper alloys excel.

Thermal and electrical conductivity further highlight the advantages of copper alloys. Their thermal conductivity ranges from 200 to 400 W/m·K, far exceeding aluminium's 150-200 W/m·K. Similarly, copper alloys deliver electrical conductivity of 20-60% IACS, outperforming both aluminium (35-45%) and zinc (25-30%). Magnesium alloys lag even further behind in both categories.

While the raw material cost of copper alloys is 2–3 times higher than aluminium and 4–5 times higher than zinc, the total cost of ownership often tells a different story. According to Mastars, the durability and reduced maintenance needs of copper alloys frequently offset their initial cost, especially in demanding applications.

| Material Property | Copper Alloys | Aluminium Alloys | Zinc Alloys | Magnesium Alloys |

|---|---|---|---|---|

| Tensile Strength (MPa) | 300-700 | 150-400 | 200-350 | 150-300 |

| Thermal Conductivity (W/m·K) | 200-400 | 150-200 | 100-120 | 50-150 |

| Electrical Conductivity (% IACS) | 20-60 | 35-45 | 25-30 | 15-25 |

| Corrosion Resistance | Excellent | Good | Fair | Poor |

| Relative Material Cost | High | Medium | Low | Medium |

These figures explain why copper alloys are often the go-to choice for industries that demand a combination of strength, efficiency, and reliability.

Mastars has long recognised the value of copper alloys in delivering unmatched performance and durability. For Australian industries like mining and automotive manufacturing, where conditions are particularly demanding, copper alloys consistently prove their worth.

One of the biggest advantages is longevity. Copper alloy components often last 2-3 times longer than aluminium parts in harsh environments. This extended lifespan translates into less downtime, lower replacement costs, and improved operational efficiency - critical benefits for industries where reliability is key.

Copper alloys also offer dimensional stability, maintaining precise tolerances even under challenging conditions. This is crucial for applications like electrical connectors, pump housings, and precision components, where even slight variations can lead to performance issues.

Another benefit is their ability to flow into complex geometries during casting. This reduces the need for post-processing and allows for intricate designs to be produced efficiently, helping to balance out the higher raw material costs.

From an environmental standpoint, copper alloys align with Australia's focus on sustainability. They are 100% recyclable without losing performance, making them an environmentally responsible choice. Additionally, their natural antimicrobial properties make them ideal for medical devices, offering a level of infection control that other die casting materials can't provide.

While the upfront cost of copper alloys is higher, Mastars has found that the overall lifecycle savings make them a smart investment. For projects requiring top-tier performance, durability, and reliability, copper alloys consistently deliver the best value. Their combination of strength, efficiency, and sustainability is hard to beat, especially in the challenging environments faced by Australian industries.

Copper alloys have proven to be a standout choice for pressure die casting in Australia, meeting the rigorous demands of industries ranging from mining operations in Western Australia to automotive production in South Australia. Their exceptional qualities deliver long-term reliability and value.

These alloys thrive in Australia's challenging environments, offering unmatched durability, reduced maintenance needs, and minimal downtime - all of which help lower overall ownership costs. Their ability to maintain dimensional stability and performance across a wide range of applications makes them a dependable option for Australian manufacturers tackling diverse challenges.

At Mastars, we combine advanced manufacturing techniques, strict quality control, and comprehensive post-casting services to meet Australia's specific industry needs. Whether it’s the heavy-duty requirements of the mining sector or the precise standards of medical device manufacturing, our expertise ensures every component meets the highest benchmarks.

Copper alloys also offer environmental advantages, such as excellent recyclability and natural antimicrobial properties - features that align perfectly with Australia's sustainability goals and regulatory frameworks. This combination of performance and environmental responsibility makes copper alloys not just a practical solution but a forward-thinking choice for manufacturers striving to meet modern demands.

For manufacturers seeking precision, durability, and sustainability, copper alloys remain a top-tier option. Backed by Mastars' dedication to quality, they represent a smart, strategic choice for Australian industries aiming for excellence.

Copper alloys are a fantastic option for pressure die casting in Australia, thanks to their durability and resistance to corrosion. These qualities make them particularly well-suited for harsh conditions like high humidity, salt exposure, and contact with chemicals - factors that are all too common in many regions across the country. Alloys such as brass, bronze, and beryllium copper are especially reliable, as they maintain structural strength while resisting wear and fatigue, making them ideal for applications under high stress.

At Mastars, we focus on crafting components using premium copper alloys, ensuring they can handle the demands of Australia's tough environments. With our expertise in pressure die casting, we deliver parts that are built to perform consistently and endure even the most challenging conditions.

Copper alloys are a smart pick for industrial use thanks to their impressive durability and strong resistance to corrosion. These qualities mean less frequent maintenance and fewer costly replacements over time. While the upfront cost might be higher, the long-term savings often make it a worthwhile investment.

Another big advantage is their excellent thermal and electrical conductivity, which boosts energy efficiency in various processes. This not only helps cut down operational costs but also makes them a reliable and efficient material choice for industries. At Mastars, we take full advantage of these properties to deliver precision-engineered pressure die casting solutions, crafted to suit the specific needs of our Australian clients.

Copper alloys are indispensable in Australia's automotive and mining industries, thanks to their ability to improve durability and performance. Known for their resistance to corrosion, superior thermal and electrical conductivity, and tolerance to extreme conditions, these materials are perfectly suited for tough, high-demand environments.

In mining, where equipment is constantly exposed to moisture, heat, and abrasive materials, copper alloys play a key role. Their resistance to wear and corrosion ensures machinery operates reliably and lasts longer, even in the harshest settings. Over in the automotive sector, copper alloys are just as critical. Components like cooling systems and electrical connectors rely on their ability to handle heat and conduct electricity efficiently, keeping vehicles running smoothly under challenging conditions.

At Mastars, we understand the specific needs of these industries. As a trusted precision manufacturing partner based in China, we provide tailored copper alloy solutions for Australian businesses. Our focus is on delivering materials that meet the highest standards of durability and performance, no matter the application.