The exterior parts of the car mainly refer to the front and rear bumpers, wheel mouths, air intake grilles, radiator hoods, rubbing strips and other parts attached to the car body by bolts and snaps or double-sided adhesive. In the exterior of the body mainly plays a decorative protection role and open and other functions.|

rapid cnc machining

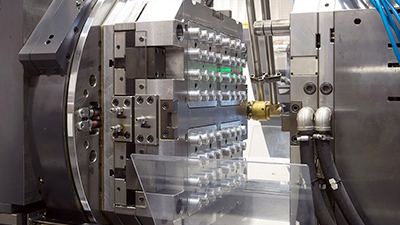

The application of thermoplastic in exterior trim parts is mainly to take advantage of its advantages in molding and processing, easy to achieve complex shapes, high production efficiency and quality consistency, while plastics can achieve relatively high performance in some aspects through synthesis and modification, such as high toughness and scratch resistance. Due to the special function of the car, the design of exterior parts must adhere to the "three" design principles of standardization, serialization and generalization, while meeting the "six" requirements of rationality, advancement, ease of maintenance, reliability, economy and manufacturing process.

From the point of view of the type of exterior materials, currently there are.

Exterior mirrors: mostly heat-resistant ABS, PC/ABS, ASA, PBT + GF and other materials.

Wheel covers: mostly PC/ABS, electroplated PC/ABS, heat-resistant ABS, electroplated ABS, PA/PPE and other materials.

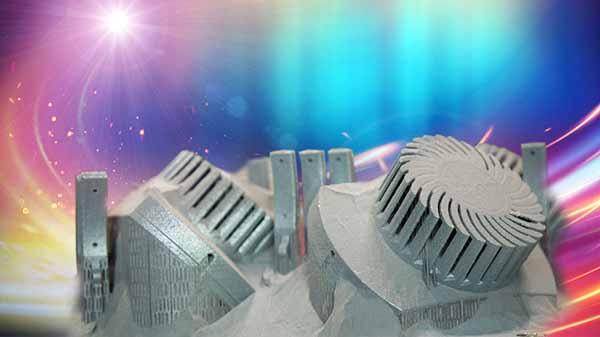

Heat dissipation grille: PC/ABS, electroplated PC/ABS, ASA, electroplated ABS, AES, heat-resistant ABS and other materials are used.

Column trim: generally choose PC/ABS, ASA, M-PMMA, AES materials.

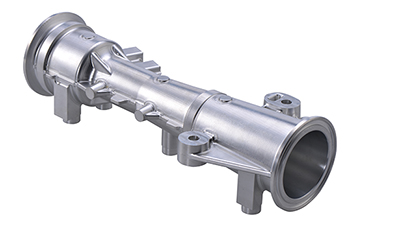

III. Automobile exterior plastic parts processing technology

1. exterior rear view mirror

(Heat-resistant ABS, PC/ABS, ASA, PBT+GF)

2. Wheel cover

(PC/ABS, electroplated PC/ABS, heat-resistant ABS, electroplated ABS, PA/PPE)

3. Tail fins

(PC/ABS,blow molding grade ABS,PC/ABS)

4. Heat dissipation grille

(PC/ABS,electroplated PC/ABS,ASA,electroplated ABS,AES,heat resistant ABS)

5. Column trim - automotive column

(PC/ABS,ASA,M-PMMA,AES)

6. Car luggage bracket

(PC/PBT,PC/ASA,PC/ABS,ASA)