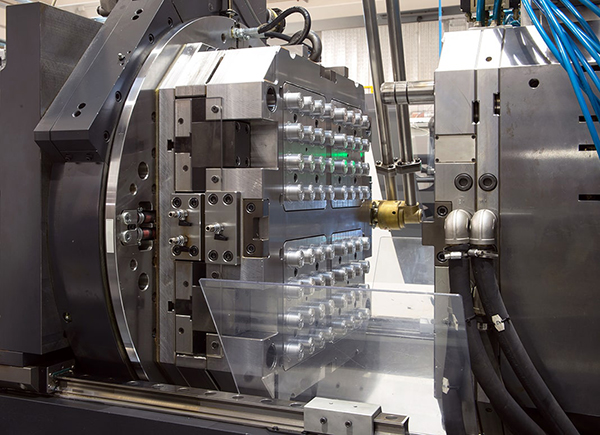

Injection Molding Defects Caused by Molding Process and Solutions

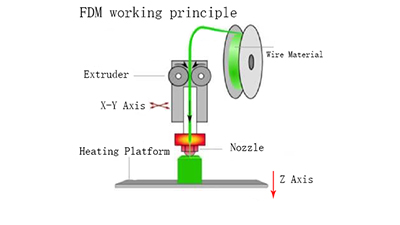

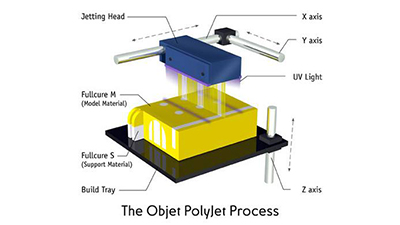

The injection molding processes are not the same for all parts. When you use any wrong method, it might cause an injection molding defect. However, you can prevent such a possibility with some simple adjustments. You need to adjust the flow rate, temperature, and some other parameters to avoid defects. In the following, we will cover some defects, causes, and their solutions.

Injection molding process is a complex process involving many factors, such as mold design, mold manufacturing, raw material characteristics and raw material pretreatment methods, molding process, injection molding machine operation, and is closely related to processing environmental conditions, product cooling time and post-treatment process. Therefore, the quality of plastic products depends not only on the injection precision and measurement precision of the injection molding machine, or only on the quality of mold design and the precision level of mold processing. Usually, it will also be affected and restricted by the above other factors.

skin needling:

Burr is caused by the overflow of molten injection resin from the parting surface of the mold, which is the worst state in the forming operation. Especially when the burr is firmly adhered to the parting surface of the die for die locking, it will damage the parting surface of the die. After the die is damaged, new burr will be generated in the formed product when it is re operated. At the same time, it also aggravates the damage of the die and makes it unusable. Therefore, special attention should be paid. (1) Do not use too high injection pressure (2) increase the clamping force (3) keep the mold properly (4) adjust the injection volume and reduce the temperature

Insufficient filling (or insufficient forming):

Insufficient molding is a molding defect formed by cooling and hardening when the molten injection resin has not completely filled the mold cavity. The main reasons are insufficient resin capacity, insufficient pressurization in the mold cavity, insufficient resin fluidity and poor exhaust effect. When the injection volume of the molding machine is sufficient and the condition of insufficient molding still cannot be improved, consider whether the injection pressure is insufficient or the set temperature of the molten resin is low.

Bubble:

Bubbles are easy to occur in the parts with thick wall thickness of formed products, and the formation reason is exactly the same as the depression of formed products. The cavity formed on the surface of the formed product is a depression, and the cavity formed in the middle of the thick wall of the formed product is a bubble. According to the causes of bubbles, the countermeasures are as follows: when the wall thickness of the product is large, the cooling speed of the outer surface is faster than that of the central part. Therefore, with the progress of cooling, the resin in the central part shrinks and expands to the surface, resulting in insufficient filling in the central part. This condition is called vacuum bubble.

The solutions mainly include:

1. Determine the reasonable gate and sprue size according to the wall thickness. Generally, the gate height shall be 50% ~ 60% of the product wall thickness.

2. Until the gate is sealed, a certain amount of supplementary injection material is left.

3. The injection time should be slightly longer than the gate sealing time.

4. Reduce the injection speed, increase the injection pressure, and use materials with high melt viscosity grade.

5. For the bubbles caused by the generation of volatile gas, the main solutions are as follows: (1) fully pre drying. (2) Reduce the resin temperature to avoid decomposition gas. Bubbles caused by poor fluidity can be solved by increasing the temperature of resin and mold and increasing the injection speed. 6. Warpage and deformation warpage and deformation of injection molded products are very difficult problems. It should be solved mainly from the aspect of mold design, and the adjustment effect of forming conditions is very limited. When the deformation is caused by residual stress caused by molding conditions, the stress can be eliminated by reducing the injection pressure, increasing the mold temperature and making the mold temperature uniform, increasing the resin temperature or annealing.

Mastars are principally engaged in the manufacture of plastic/metal parts business including automotive, industrial and moulds. As manufacturing expertise in China, we provide philosophy, customers benefit from our unique blend of philosophy, customers benefit from our unique blend of quality, reasonable cost, integrated services and flexibiliy.

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China