If your

rapid prototyping or functional parts need surface treatment, please contact

mastars. We will develop the

best solution for you and provide you with products and

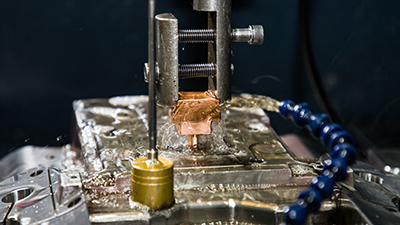

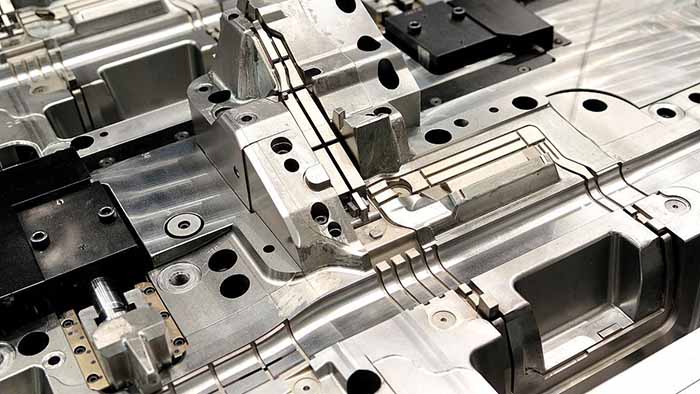

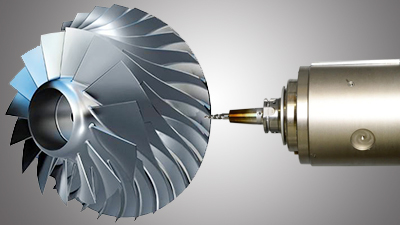

one-stop services that exceed your expectations. Mastas is a global company providing industrial manufacturing services. Its business scope is as wide as CNC application, and CNC is one of its main processing technologies.

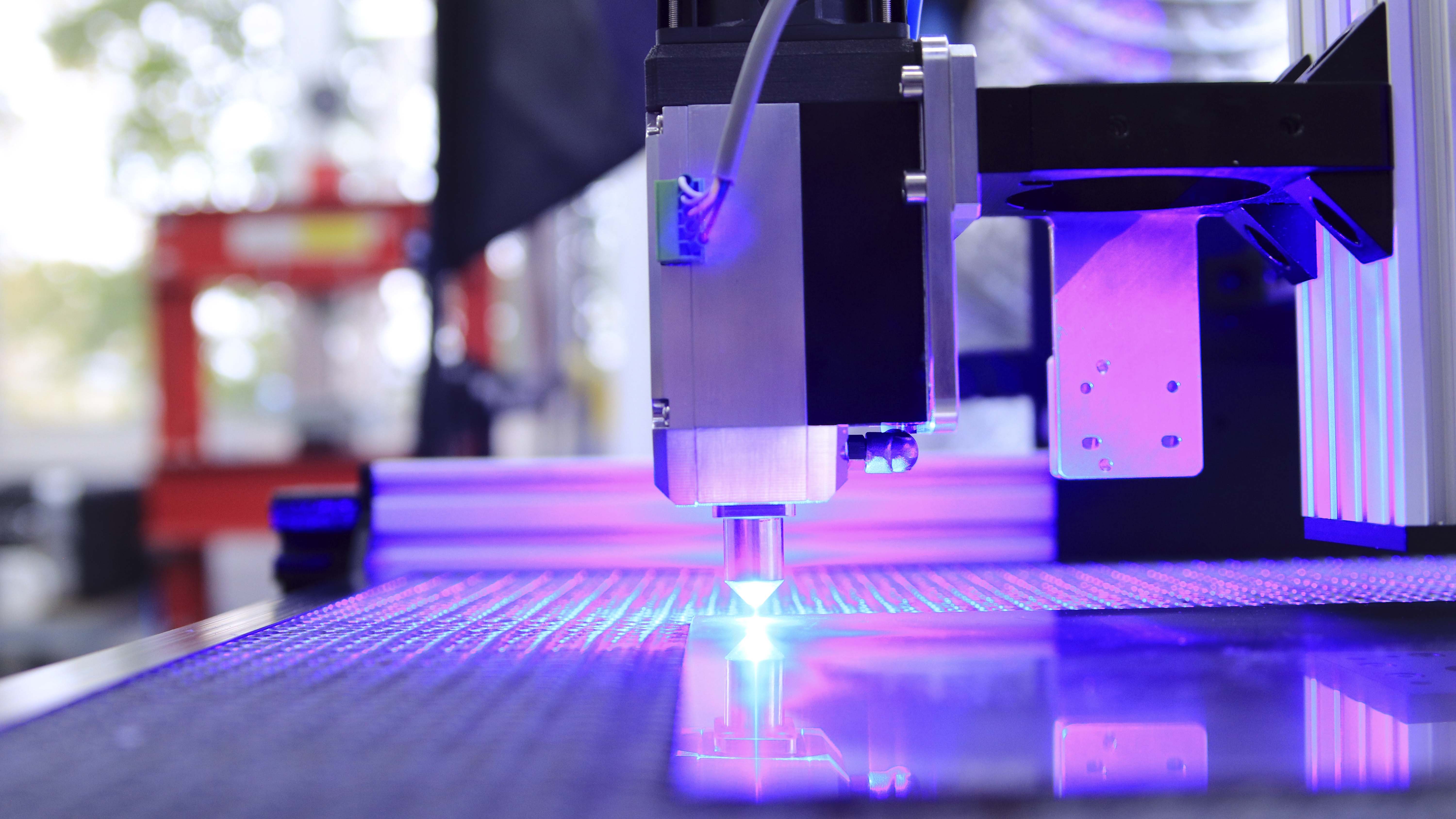

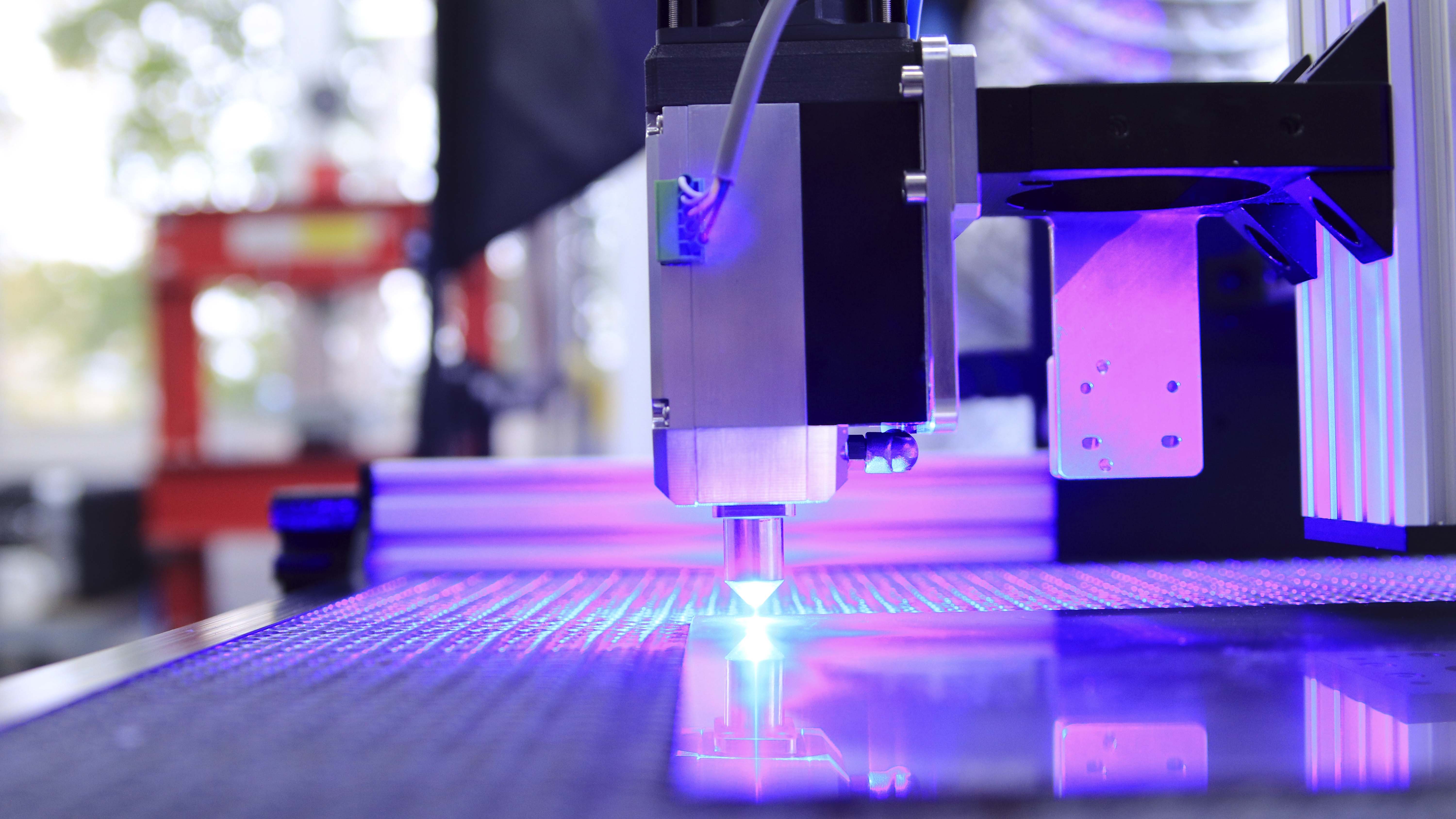

Laser engraving is a surface treatment process based on the optical principle. It is mostly used on the keys of mobile phones and electronic dictionaries. It is to carve traces through the change of surface materials caused by the light energy of laser beam, or burn some materials through the light energy to show the graphics and characters to be etched; According to different engraving methods, it can be divided into dot matrix engraving and vector cutting.

Dot matrix Engraving - similar to high-definition dot matrix printing; The laser head swings left and right to carve a line composed of a series of points each time, and then the laser head moves up and down at the same time to carve multiple lines, and finally form a full page image or text; The scanned graphics, text and vectorized graphics and texts can be engraved with dot matrix.

Vector cutting is different from dot matrix carving. Vector cutting is carried out on the outer contour of graphics and text. This mode is usually used for penetration cutting on wood, paper, acrylic and other materials. It can also be operated on the surface of a variety of materials!

Laser engraving is a kind of surface treatment process, which is similar to screen printing and pad printing. It prints words or patterns on products. Different processes have different prices.

The products produced by laser engraving and silk screen printing have the same visual effect from the appearance, but there are still great differences in practice. The following is a brief introduction to their differences:

① For laser carved products, the font and pattern have light transmittance; Silk screen printing products are opaque.

② For laser engraving products, the color of font and pattern is the color of material, and the background color is the color of ink; Silk screen printing products are just the opposite of laser engraving products.

③ In terms of wear resistance, laser engraving is higher than silk screen printing

④ The principles of the two processes are different. The optical principle used in laser engraving is surface treatment, while silk screen printing is a physical principle, which allows the ink to adhere to it.

⑤ The price is different, but the price is judged by the difficulty of font and pattern.

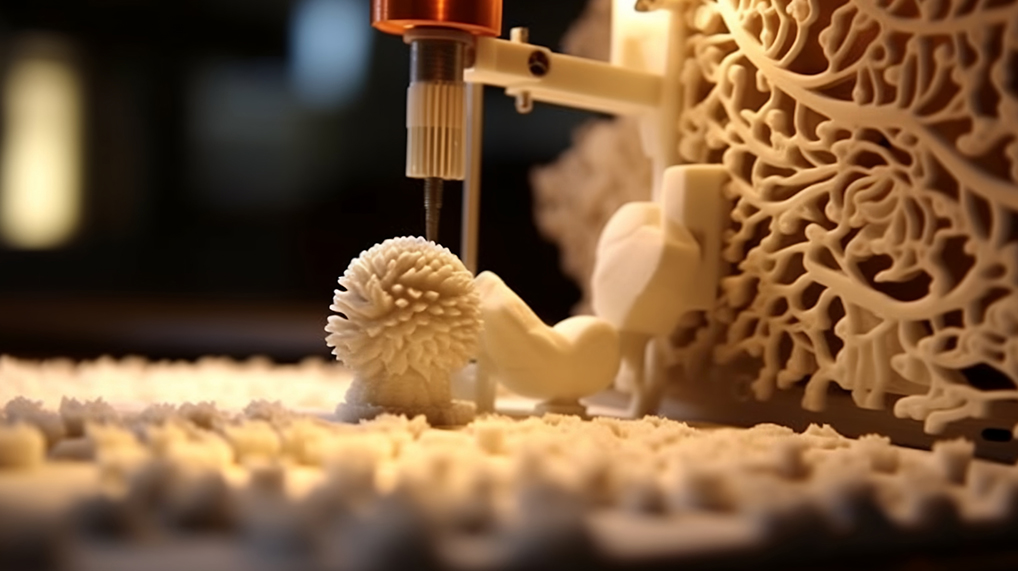

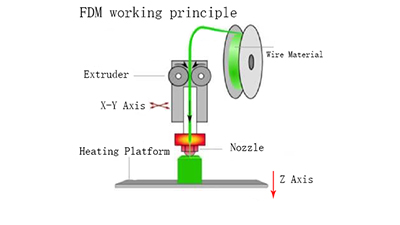

Mastars' rapid prototyping service can provide various 3D printing prototyping services according to customers' needs, verify your designed, provide fast, efficient and cost-effective services, and lay the foundation for future mass production of your products.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China