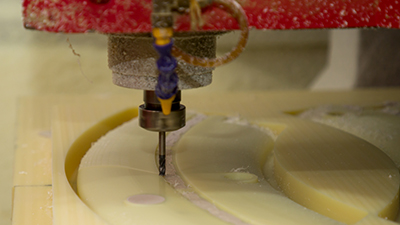

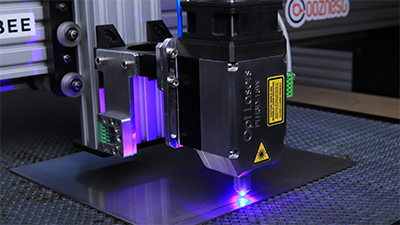

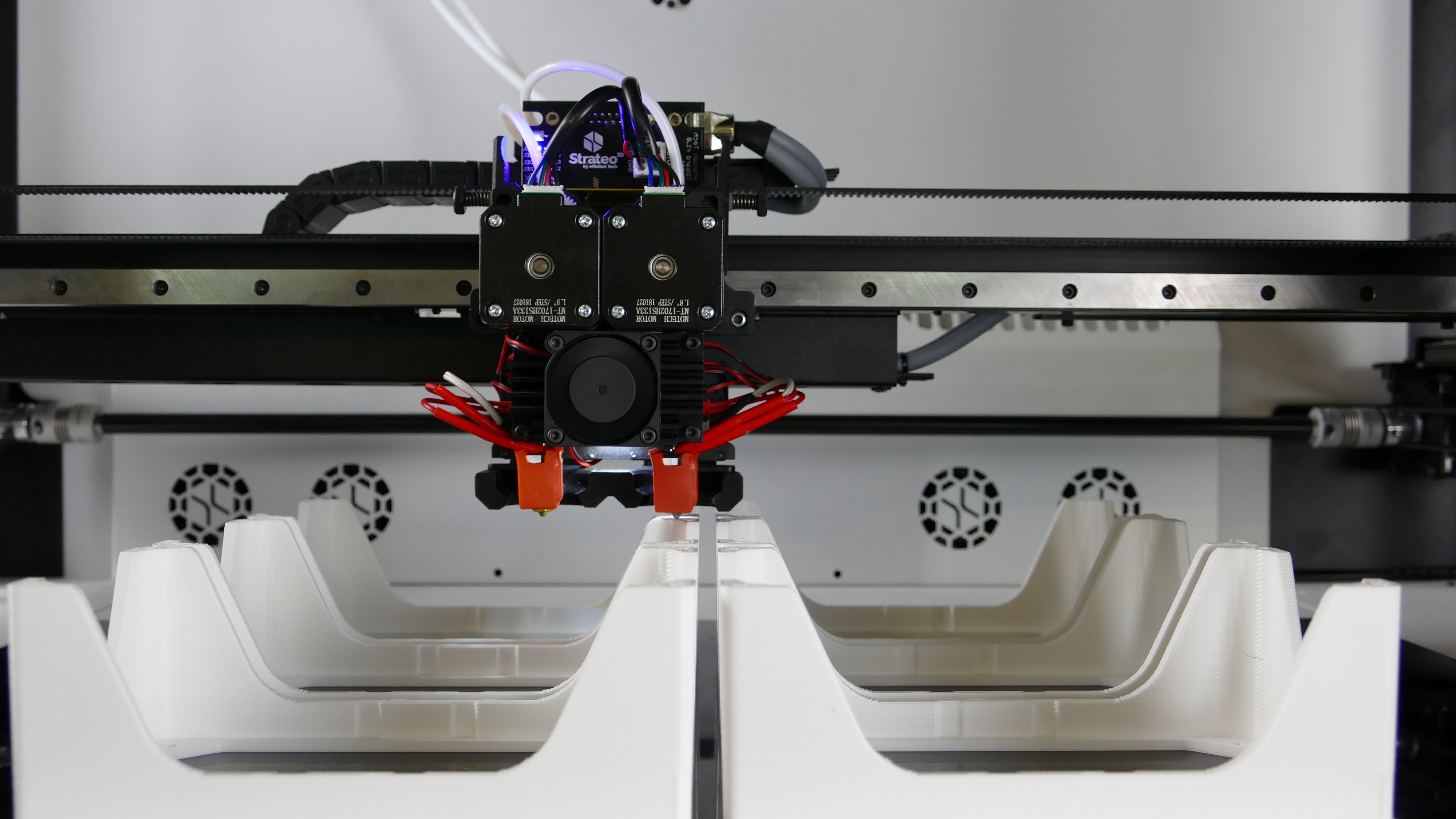

Mastars' rapid prototyping service can provide various prototyping services according to customers' needs, verify your designed, provide fast, efficient and cost-effective services

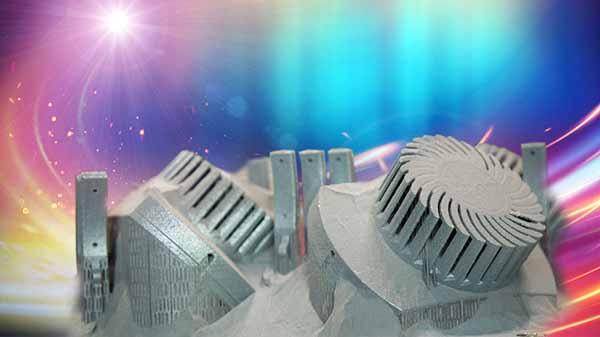

Stainless steel was invented nearly 150 years ago and is still popular today. It is made by smelting the steel itself in combination with iron and carbon (sometimes other metals such as nickel), and adding chromium and molybdenum to prevent rust and corrosion. Chromium promotes the passivation of steel and keeps the steel in a stable passive state. With the increase of molybdenum content, the high temperature strength of the steel is improved, such as durability, creep and other properties are greatly improved.

Researchers have made a "breakthrough" in the field of 3D printing of 316L stainless steel, a common "marine grade" stainless steel with low carbon composition. It is widely used in oil pipelines, engine parts and kitchen equipment, and usually has low corrosion and high ductility. Excitedly, tests have shown that the rugged and wear-resistant 3D printed 316L stainless steel can provide higher levels of strength and ductility than other forms of steel, making it useful for chemical equipment, medical implants, engine parts and various other applications that require excellent physical properties of its equipment.

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China