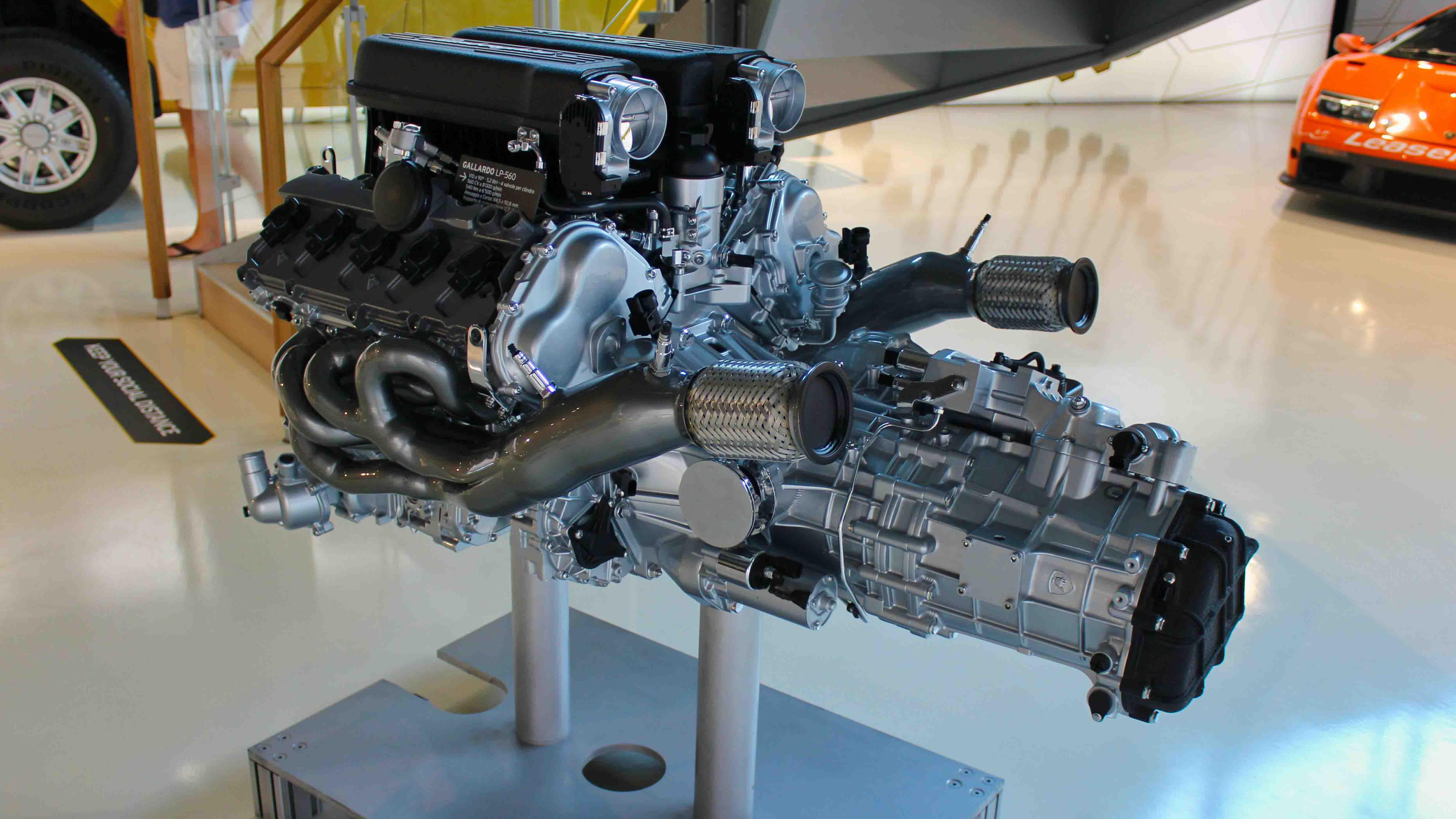

Injection molding technology has become the main mass production mode of plastic products since it was popularized because it can produce complex products quickly, in batches and at low cost. However, the high cost and long cycle of manufacturing molds required for injection molding are still the pain points in front of enterprises.

With the breakthrough in the performance of

3D printing materials, some

3D printing materials with both temperature resistance and high strength can replace the traditional metal injection molds in the field of small batch manufacturing, which greatly reduces the time cost and economic cost of production.

3D printing replaces traditional mold manufacturing

As enterprises have more and more personalized requirements for production, and the demand for pre production trial production is more and more frequent, the traditional way of using CNC to process metal molds has been difficult to meet the dual requirements of small batch manufacturing for delivery time and cost.

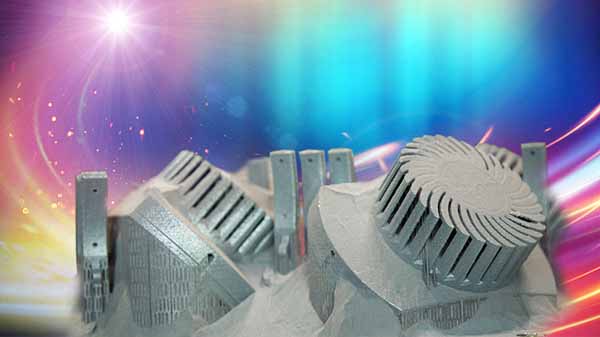

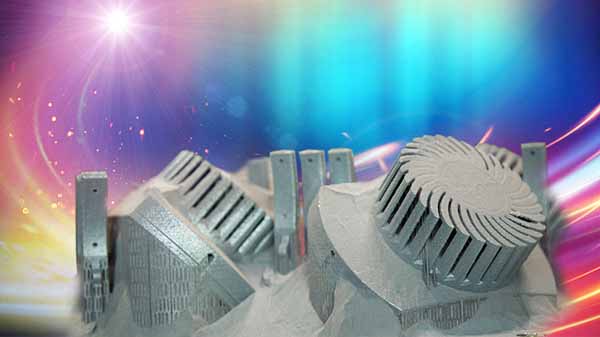

High strength photosensitive resin material Somos ® Perform, the thermal deformation temperature of the products produced by it can reach 260 ℃ after post heat treatment. Its tensile modulus reaches 10500mpa and bending modulus reaches 10000mpa. It can be used to produce strong, tough and high temperature resistant composite parts, especially for mold making, wind tunnel testing and other application scenarios.

lower cost and higher efficiency

For small batch manufacturing, compared with expensive metal molds, using 3D printing technology to make injection molding molds has more time and cost advantages, and gives enterprises more flexible production capacity. For example, more economic benefits can be obtained when serving small batch manufacturing orders less than 1000pcs, or in large batch orders, multiple tests and verifications can be conducted for the mold design before opening the metal mold, or the design scheme can be quickly adjusted to ensure the accuracy of the final mold.

professional service team

The complexity of injection molding process is mainly determined by the complexity of the structure of finished products and production molds. Therefore, before 3D printing, in addition to mastering the design skills of components and molds, it is equally important to formulate a 3D printing scheme to ensure that the products can meet the later use requirements. The technical support team of mastars will efficiently develop solutions according to the specific needs of users to help you better serve customers.

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China