2022 Full Guide for Metal Parts Manufacturing

The manufacturing of metal parts necessitates the use of specific techniques and applications. It’s a long manufacturing process that entails learning about casting, machining, breaking, and plating. To make sure that metal parts manufacturing is completed at a high rate, designers must be well-versed in the characteristics of different kinds of metals, their compositions, and part polishing.

In the process of part manufacturing, from the design drawing of parts to the delivery of parts, not only the numerical programming, but also the influence of a series of factors such as the arrangement of part process route, the selection of machine tool, the selection of cutting tool, positioning and clamping should be considered. Before starting the programming, the detailed NC process analysis of part design drawings and technical requirements must be carried out, In this way, we can avoid the possible quality problems caused by poor consideration of the process scheme, resulting in unnecessary waste of human, material and other resources. The following is a brief introduction to the manufacturing process and precautions of metal parts:

Get basic information of parts

(1) Part design drawings, technical data, assembly drawings and batch of parts.

(2) Relevant technical standards required for parts, such as enterprise standards, process documents and quality standards for acceptance.

(3) Manufacturing capacity of existing process equipment and special equipment, specification and performance of process equipment, and technical level of workers.

Analysis of manufacturing process flow of parts

Analyze the shape and size of parts, as well as the type, specification, shape, heat treatment state and hardness of raw materials. Using these original information is conducive to NC planning.

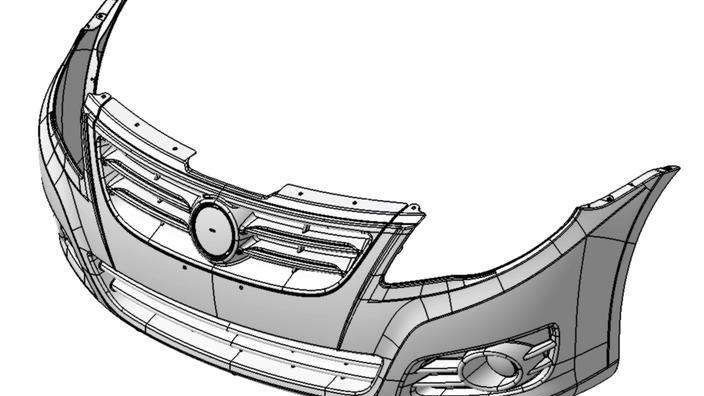

(1) Assembly drawing and part drawing analysis

For the analysis and research of assembly drawing, it is mainly to be familiar with the performance and purpose, clarify the mutual assembly position and function of parts, understand the basis for the formulation of various technical conditions on the part drawing, find out the main technical key problems, and lay the foundation for the formulation of correct scheme. Of course, when analyzing the process of ordinary parts, the analysis and research of assembly drawing can not be carried out.

(2) Process analysis of part drawing

The analysis and Research on the part drawing mainly focuses on the process review of the parts, such as checking whether there are errors and omissions in the view, dimension and technical requirements of the design drawing, especially for the parts with poor structural manufacturability, if possible, communicate with the designer or put forward modification opinions, and the Designer shall decide whether to make necessary modifications and improvements.

(3) Integrity and correctness analysis of part drawing

The view of parts shall meet the requirements of national standards, with accurate position and clear expression; The relationship between geometric elements (points, lines and faces) (such as tangency, intersection and parallelism) shall be accurate; The dimensions shall be complete and clear.

3D printing (

Mastars provides resin, nylon, metal 3D printing services)

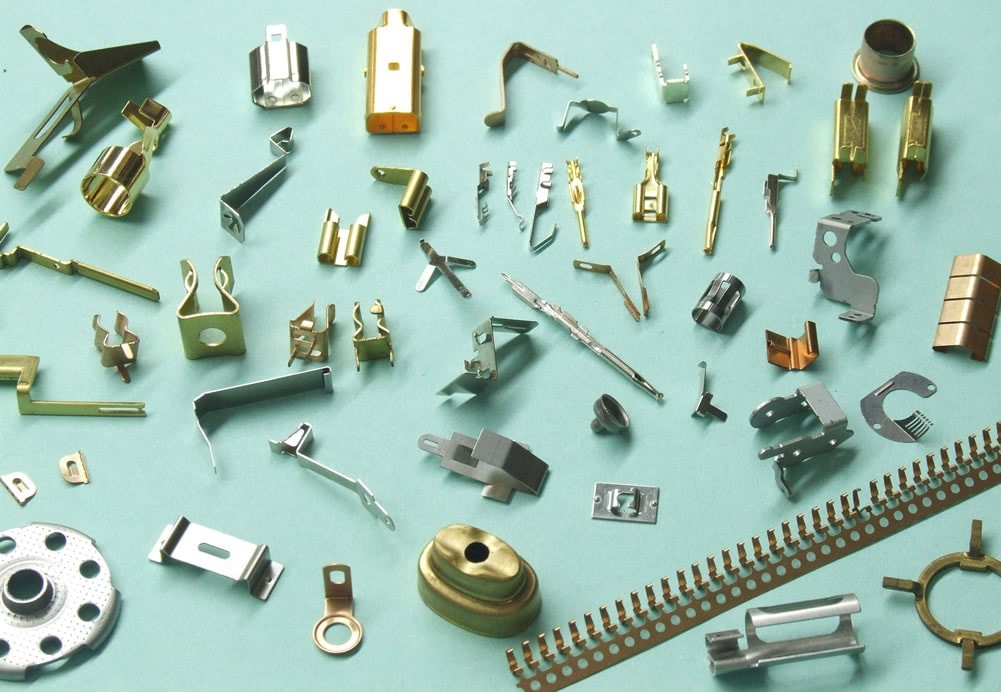

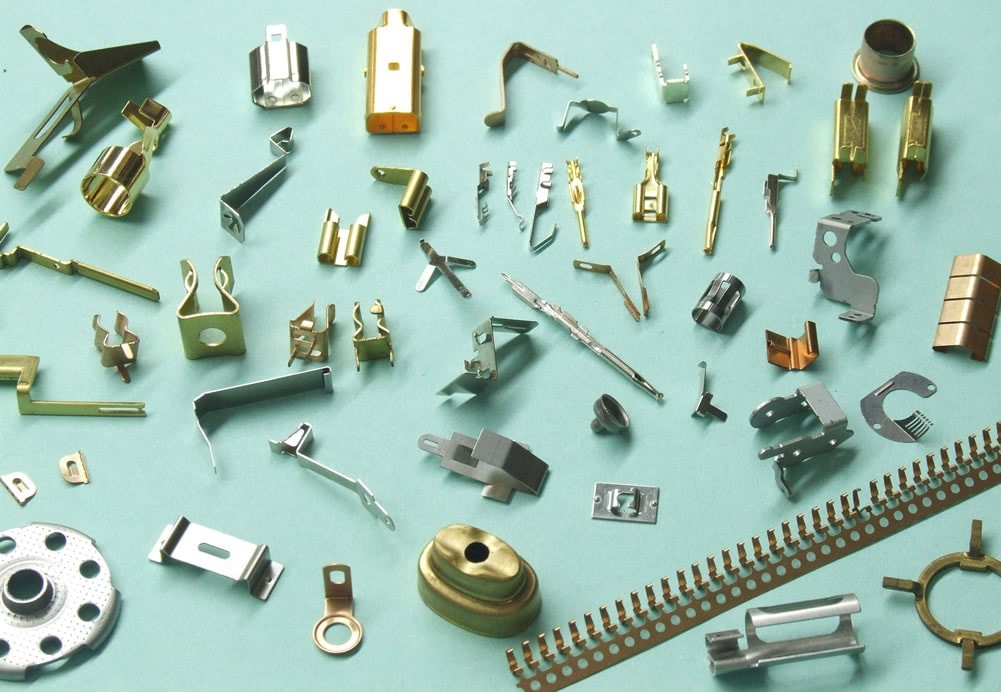

Die casting

Die casting Die casting is a metal casting process, which is characterized by using the inner cavity of the die to apply high pressure to the molten metal. Molds are usually made of alloys with higher strength. This process is somewhat similar to injection molding.

Metal injection molding

metal injection molding It is a technological process of preparing metal powder and using the powder of metal or alloy (or the mixture of metal powder and non-metallic powder) as raw material to obtain part products through forming and sintering

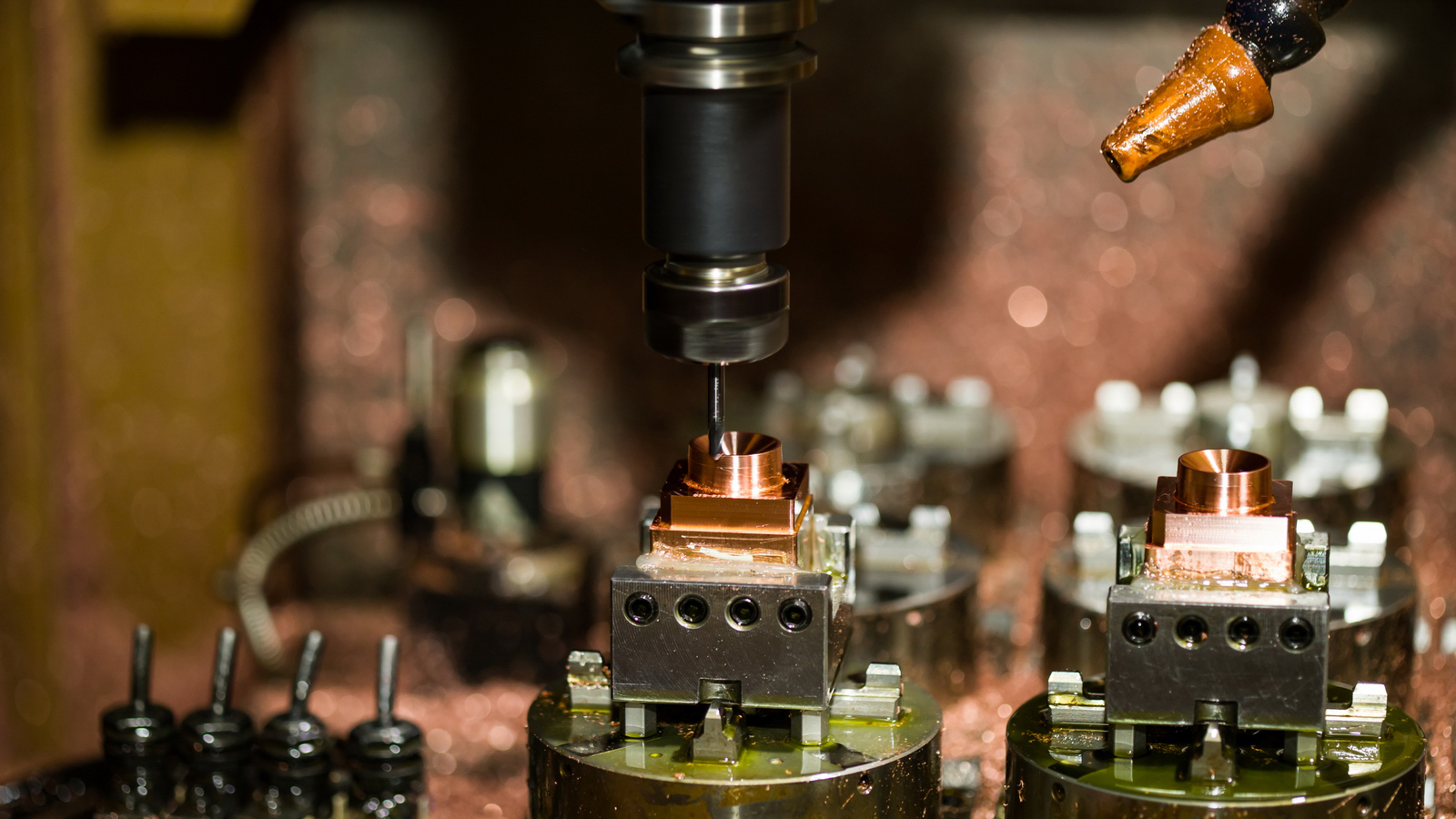

Select appropriate machine tool equipment

Although CNC has strict CNC machine tool operation specifications and good machine tool maintenance, its own precision loss is inevitable.

(1) In order to control the quality, we regularly carry out inspection and maintenance on the CNC equipment, define the accuracy of each equipment and the task of each equipment.

(2) Strictly distinguish the use of rough and precision equipment, because rough work pursues high speed, high removal rate and low precision, while precision work is the opposite. Achieve a reasonable allocation of existing equipment resources and a clear division of labor, minimize the impact of machine tools on quality, protect expensive CNC equipment and prolong the service life of the equipment.

4、 Precautions for selection of cutting oil

Cutting oil is a medium that must be used in metal cutting process. It mainly plays the role of lubrication, cooling and cleaning in the process.

(1) The special cutting oil contains vulcanized extreme pressure anti-wear additives, which can effectively protect the tool and improve the process accuracy.

(2) Compared with rapeseed oil, mechanical oil and recycled oil, the special cutting oil has good stability and will not harm the equipment, human body and environment.

(3) The special cutting oil has passed strict tests in viscosity, flash point, pour point and thermal conductivity to meet the needs of various cutting processes.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210689

Fax: +86 755-8821 0685

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China.