Mastars is dedicated to the extrusion,

injection molding, and machining of various plastic products. We specialize in PEEK, PI, PPS, PEI, and provide special engineering plastic finished parts and semi-finished profiles for different industries.|

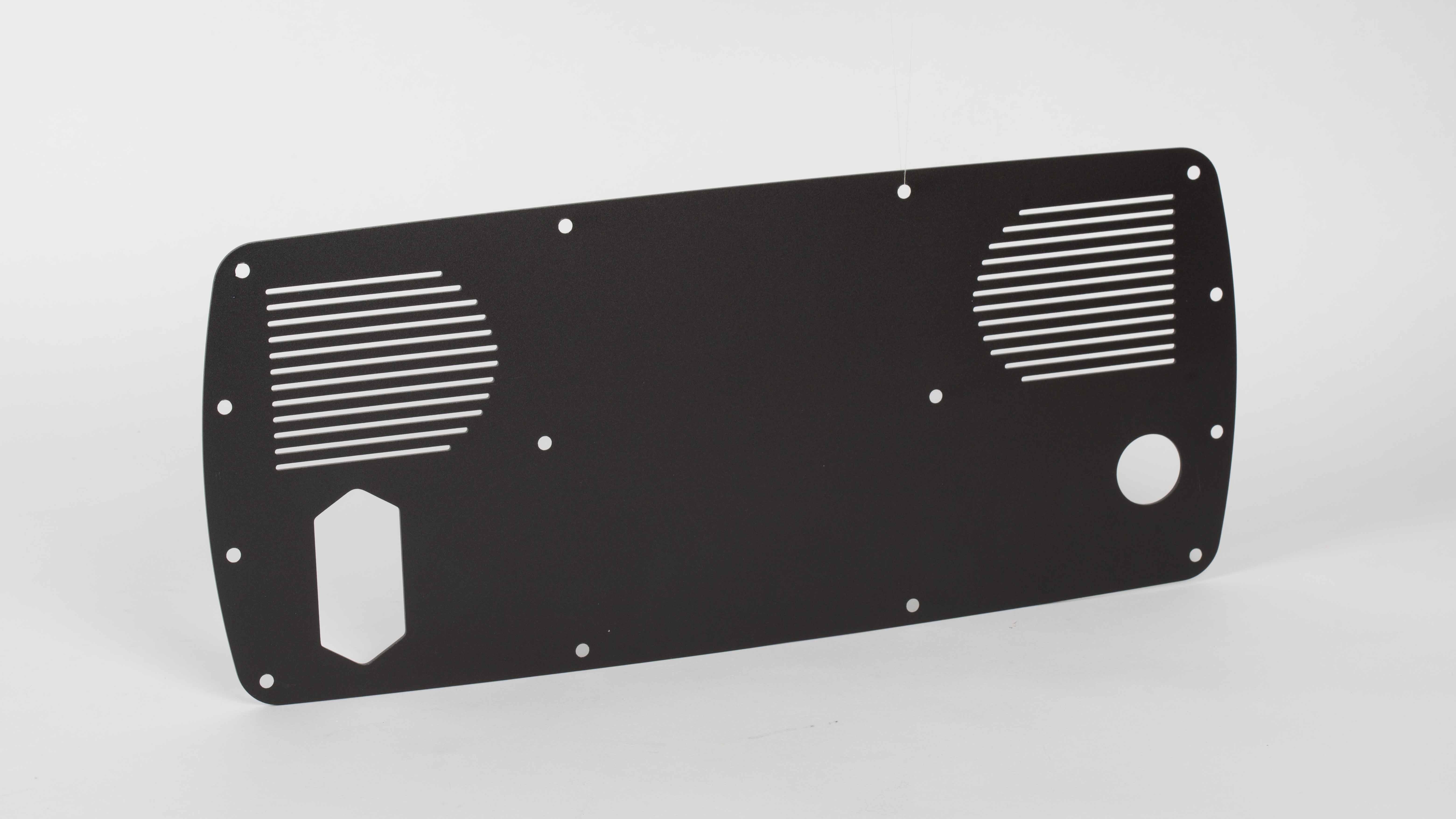

rapid cnc machining|

custom metal stamping

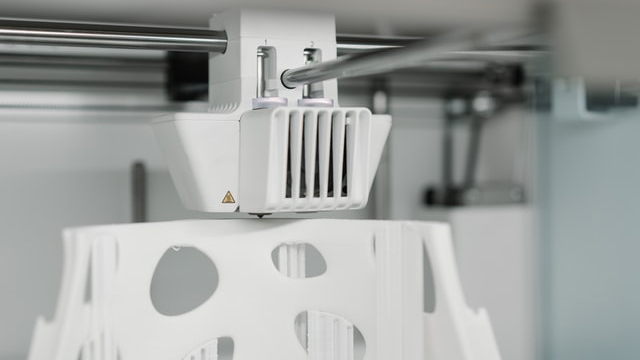

Since the emergence of 3D printer, because of its high safety factor and strong operability, it has attracted more and more attention from amateurs.

During the printing process, due to the splashing of powder particles, small bumps are often formed on the parts, resulting in rough surface of the parts, which is a headache for many users.

In particular, metal parts printed by metal 3D printers have undergone a large number of post-treatment processes such as CNC processing, shot blasting or sand blasting before they are placed in the showroom, so their surfaces are easy to be uneven

At present, many methods have been developed to solve the surface finish of metal parts in the construction process, including machining, laser ablation and etching, electrochemical machining and so on.

Four common solutions

The surface roughness problem of 3D printing parts has existed for a long time. At present, there are four common solutions to it:

1、 Use smaller raw materials

The 3D printer adopts the method of layered printing, so if the raw material powder is small enough, the surface finish of the parts will be greatly improved. However, this method will increase the material cost, so it is necessary to strike a balance between the surface finish and the cost. This method should also be considered in all aspects during specific use.

2、 Manual processing

Manual processing mainly uses sandpaper, file, hammer chisel, wire brush and other tools to polish the parts to achieve the desired results. This method can only be used for 3D printing enthusiasts to print small and uncomplicated parts. For complex or mass-produced parts, this method is completely undesirable.

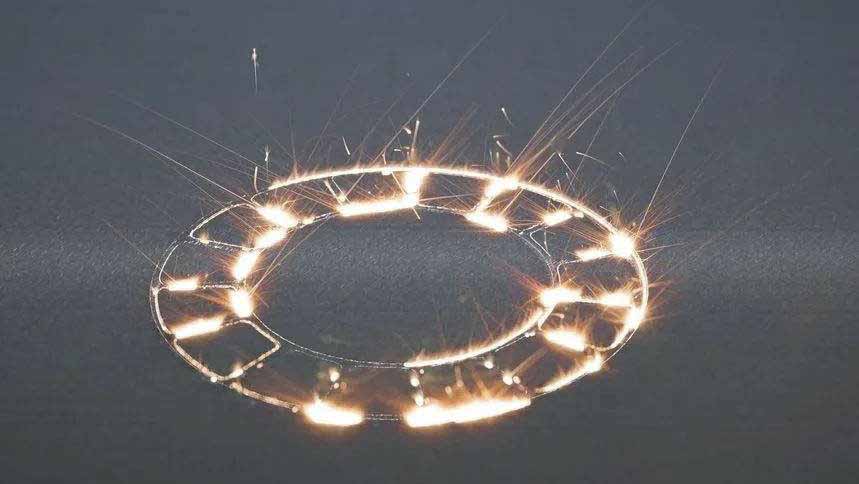

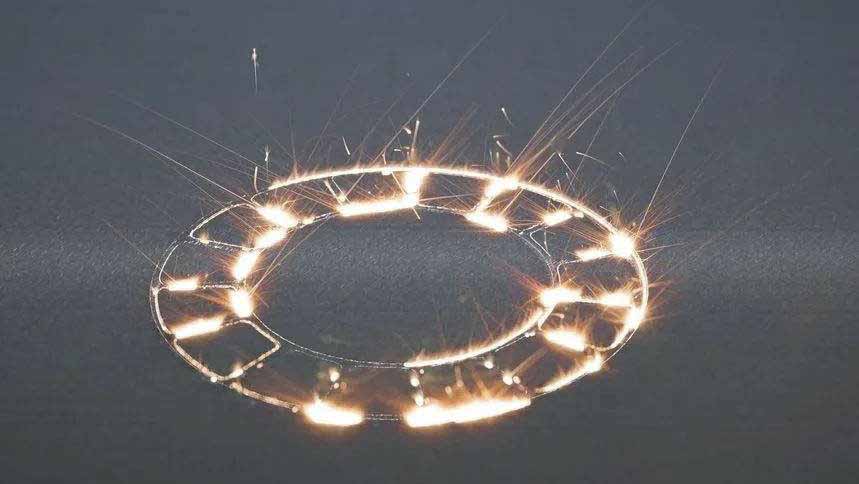

3、 Sand blasting

This method uses the impact function of high-speed sand flow to deal with the surface irregularities of

3D printing products.

In the process of processing, air compression is used as the power to spray abrasive (such as quartz sand) to the surface of 3D printing parts to be produced in a closed space at a high speed in the form of spray bundles, so that the surface of parts is changed. However, due to the impact force, this method can only be used for heavy 3D printing parts. If the parts are light and thin, they will be directly damaged by the abrasive.

4、 chemical treatment

This method is mainly used for printing products with ABS resin as raw material, and acetone is usually used as reagent.

The processing speed of this method is very fast, and it can ensure that the primary color of 3D printed parts remains unchanged. However, it should be noted that acetone is a toxic and corrosive agent. During use, be careful that too much of the agent corrodes parts, and prevent acetone from escaping to cause harm to human body.

In addition to the above four common processing methods, there are many processing methods, but each method has its advantages and disadvantages. The specific choice depends on the situation when using it.

No matter which processing method is used, it is a post-processing from the perspective of manufacturing process. If this problem can be solved in the printing process, it will save a lot of time and cost.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China