To make a set of molds that can be called tall, we not only need to have a superb mold design level and precise processing technology, but also need to have a precise mold development concept. What is the concept of precise mold development? Many people don't think so, thinking that they have made so many molds. How can there be no precision concept? In fact, the mold is not how much you do, but whether your mold development pursues excellence in detail and reliable standards. This process will never allow the existence of "almost" concepts.

1. The contents of the mold nameplate are complete, the characters are clear and arranged neatly.

2. The nameplate shall be fixed on the mold foot near the mold and the reference angle. The nameplate is fixed reliably and not easy to peel off.

3. The cooling water nozzle shall be plastic block water nozzle. If the customer has other requirements, it shall be followed.

4. The cooling water nozzle should not extend beyond the surface of the mold base.

5. The cooling water nozzle needs to be processed with counterbore, which has three sizes: 25mm, 30mm and 35mm in diameter. The orifice chamfer should be consistent.

6. The cooling water nozzle shall be marked with inlet and outlet.

7. The English characters and numbers marked should be greater than 5/6, located at 10mm below the nozzle, and the handwriting should be clear, beautiful, neat and evenly spaced.

8. Mold accessories shall not affect the hoisting and storage of molds. There are exposed oil cylinders, water nozzles, pre reset mechanisms, etc. under the installation, which should be protected by support legs.

9. The installation of support legs shall be fixed on the mold base with screws passing through the support legs, and the overly long support legs can be fastened on the mold base with externally threaded columns processed by vehicles.

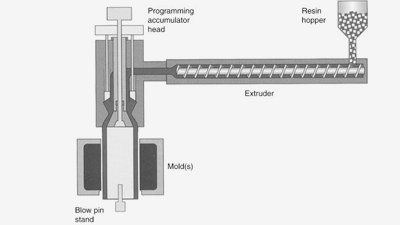

10. The size of the ejection hole of the mold shall meet the requirements of the designated injection molding machine. Except for small molds, it is not allowed to eject with only one center.

11. The locating ring shall be fixed reliably. The diameter of the ring is 100mm and 250mm. The locating ring is 10~20mm higher than the bottom plate. Unless otherwise required by the customer.

12. The overall dimension of the mold shall meet the requirements of the designated injection molding machine.

13. For molds with direction requirements, the installation direction shall be marked with an arrow on the front formwork or the rear formwork, and there shall be the word "up" next to the arrow. The arrow and text are yellow, and the word height is 50 mm.

14. The surface of the formwork shall be free of pits, rust, redundant lifting rings, water vapor in and out, oil holes and other defects that affect the appearance.