We all know that 3D printing technology consists of three parts: molding process, 3D printing materials, high-precision 3D design, and powerful molding equipment. The importance of 3D printing materials to the development of 3D printing is self-evident. At present, there are about 200 kinds of 3D printing materials on the market, which usually have high requirements for heat resistance, flexibility, stability and sensitivity.

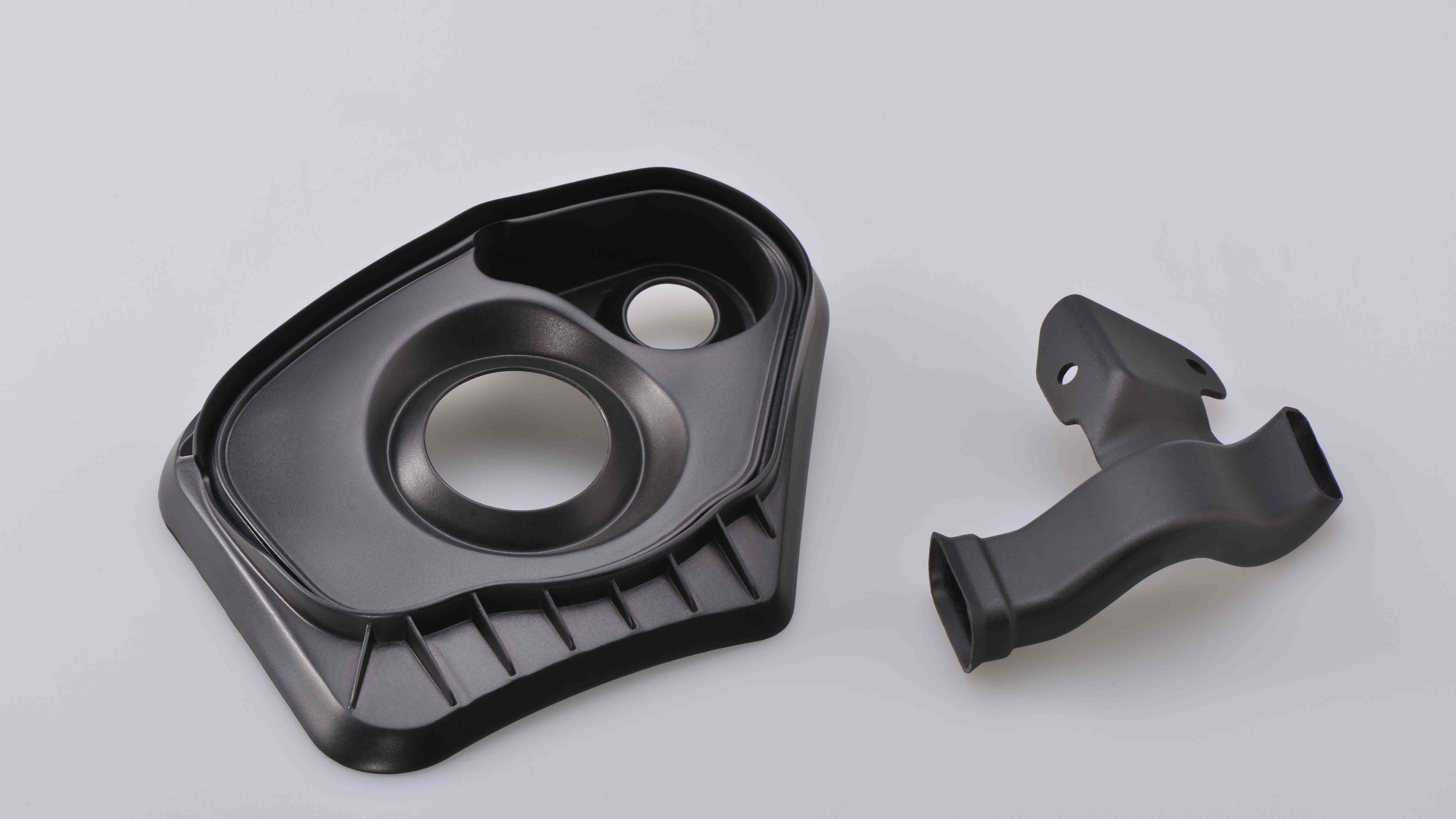

As the most widely used 3D printing material at present, engineering plastics account for more than 90% of commercial 3D printing materials and are used in FDM equipment. It mainly includes thermoplastic materials and thermosetting materials. At present, common engineering plastics mainly include the following categories:

1、 ABS engineering plastics: ABS is a popular thermoplastic 3D printing material with good hot melt and impact strength. Its advantage is that the printed parts have good mechanical strength and high stability. At the same time, it can support the use of soluble supporting 3D printing materials, and can make a variety of color choices.

2、 PC white engineering plastic can be combined with fdm3d printing technology to produce durable models, tools or final product parts. PC material has the advantages of better strength, heat resistance, impact resistance and so on. It can be widely used in automobile manufacturing, aerospace, medical devices and so on

3、 PA engineering plastics: it has high mechanical strength, certain flexibility, heat resistance and friction resistance. The PA material developed by STRATASYS company has effective strength characteristics and fatigue resistance, and can resist medium corrosive chemicals. It is suitable for repeated closure, snap type and anti vibration parts, and is superior to the strength and toughness of other thermoplastics.

4、 Ppsf Engineering Plastics: ppsf is the best 3D printing material of engineering plastics. It not only has good heat resistance, but also has very high strength and corrosion resistance. It can be used in aerospace, transportation and medical industries as parts.

5、 Peek engineering plastic: PEEK is a special engineering plastic with excellent properties such as high temperature resistance, self lubrication, easy processing and high mechanical strength.

6、 EP Engineering Plastics: EP engineering plastics, commonly known as elastic plastics, is a 3D printing material newly developed by the famous shapeways company in the United States. It can avoid the vulnerability of wearables or deformable products when used.