Mastars specialize in CNC machining /CNC Rapid prototyping/3D printing/Vacuum die casting/metal prototype maker . Familiar with casting, extruding,forging, CNC machining, moulding, custom metal stamping,and also finish treatments.

Acrylic, also known as PMMA, is an amorphous polymer, commonly known as plexiglass. It has good transparency and excellent heat resistance. This kind of material has strict processing requirements. Because it is very sensitive to moisture and temperature, it is prone to "cavity" phenomenon. Therefore, it is often processed by "low material temperature, high mold temperature and slow" injection.

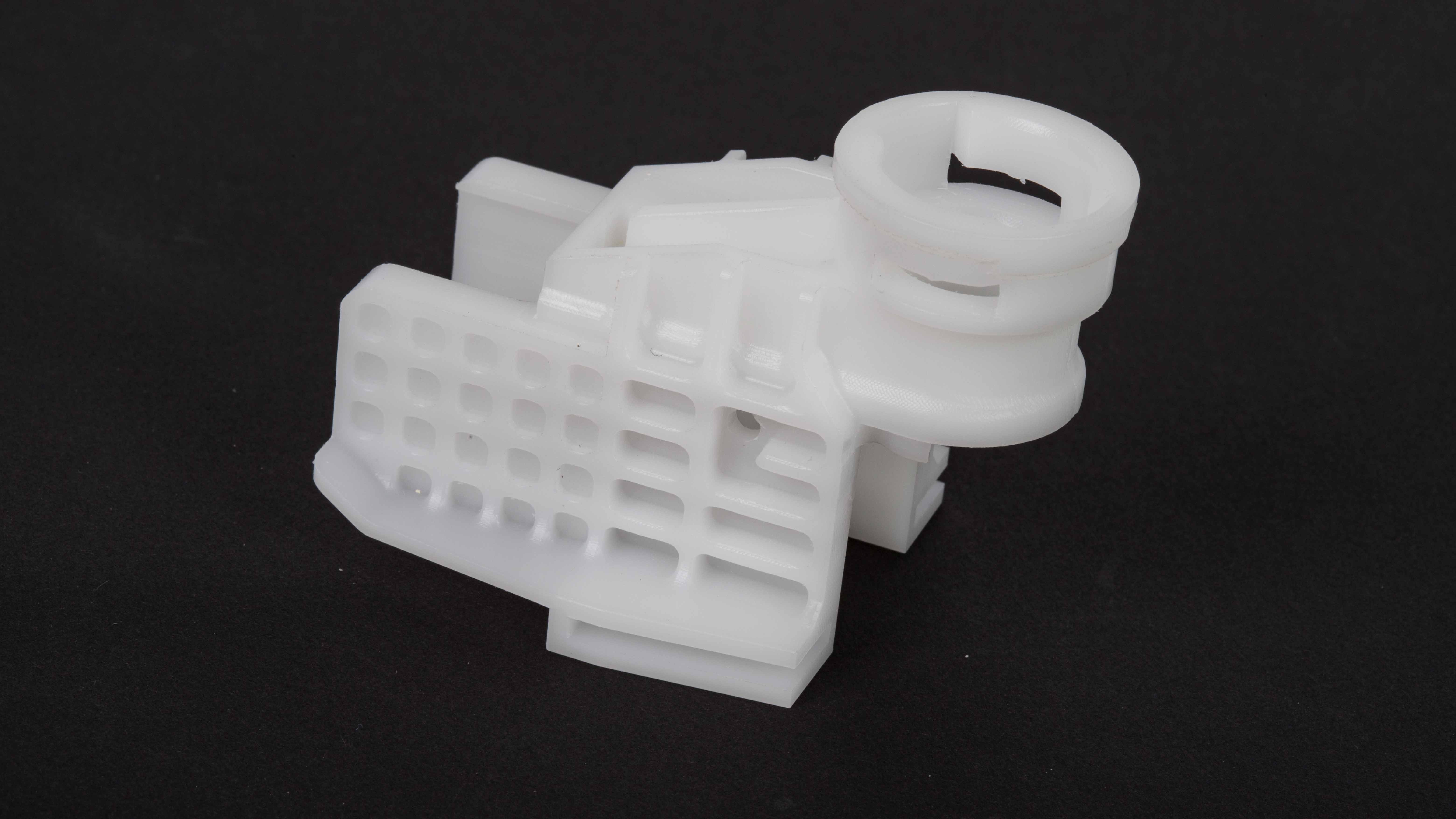

POM is a kind of material with smooth surface and good gloss. It is light yellow or white and has good comprehensive properties. It is worth noting that this material is hard to use, but it has good tensile strength, bending strength, fatigue strength, wear resistance and electrical properties.

High impact strength, good dimensional stability, colorless and transparent, good colorability, good electrical insulation, corrosion resistance and wear resistance, but poor self lubrication, stress cracking tendency, easy hydrolysis at high temperature and poor miscibility with other resins. Suitable for making small instrument parts, insulating transparent parts and impact resistant parts

The relative density of ABS material is about 1.05, and it is not easy to absorb moisture. The key is that when making the ABS hand model, the effect of disassembling and then bonding is very good. It has strong firmness and has obvious advantages over other materials. In addition, ABS material also has impact resistance, corrosion resistance and low temperature resistance. Compared with ordinary thermal substances, ABS is widely used in industries and fields such as home appliances, chassis, toys, automobiles, mechanical instruments, etc., and has become one of the engineering plastics with the widest application range

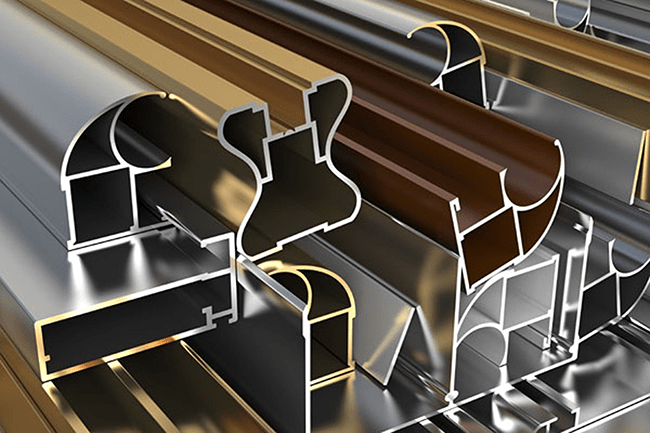

Aluminum alloy has low density, high strength, good conductivity, thermal conductivity and corrosion resistance. It can be processed into various profiles. It is a widely used material.

Stainless steel is the abbreviation of stainless and acid resistant steel. In general, the steel resistant to weak corrosive media such as air, steam and water or stainless is called stainless steel, and the steel resistant to chemical media (such as acid, alkali and salt) is called acid resistant steel. Due to the difference in chemical composition between the two, their corrosion resistance is different. The model should be selected according to the actual situation.

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

+86 18100294997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China