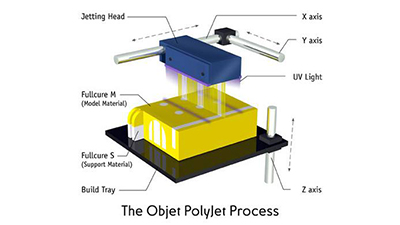

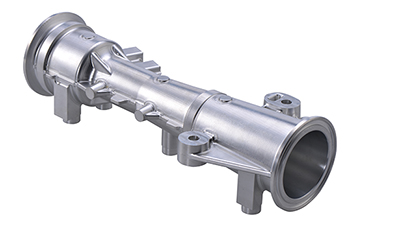

Mastars specialize in CNC machining /CNC Rapid prototyping/3D printing/Vacuum die casting/metal prototype maker . Familiar with rapid prototyping services, extruding,forging, CNC machining, moulding, custom metal stamping,and also finish treatments.

Machined parts are the general term of machining, which refers to the processing technology of removing raw materials according to the precise machining of machinery. Finish machining, that is,

precision machining, is the processing completed by high-precision processing machinery. The path to realize the precision machining of parts includes: Machining high-precision parts with high-precision CNC lathe; Using deviation compensation technology to improve the machining precision of parts. The key of machining includes manual machining and CNC machining.

Sheet metal part is a comprehensive cold working process for sheet metal (usually below 6mm), including shearing, punching / cutting / composite, folding, electric welding, riveting, patching, forming (such as vehicle body), etc. Its remarkable feature is that the thickness of the same part is consistent. The equipment processed according to the sheet metal process is called sheet metal parts. The way to distinguish whether a part is a sheet metal part or a machined part on a mechanical drawing is to see whether the thickness of the part is consistent. The thickness of sheet metal parts is consistent, but the thickness of machined parts is not consistent.

Both sheet metal drawing and part drawing need to be made by the first angle projection method. It is not allowed to release the engineering drawings from the third perspective to the production workshop for application. Unless the customer's engineering drawings are in the image file format or PDF file format that is difficult to convert, but the main view of the third triangle must be clearly marked, otherwise it shall be implemented in accordance with the first corner. The drawing method of holes on the sheet metal drawing shall comply with the national standard drawing method and relevant requirements.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China