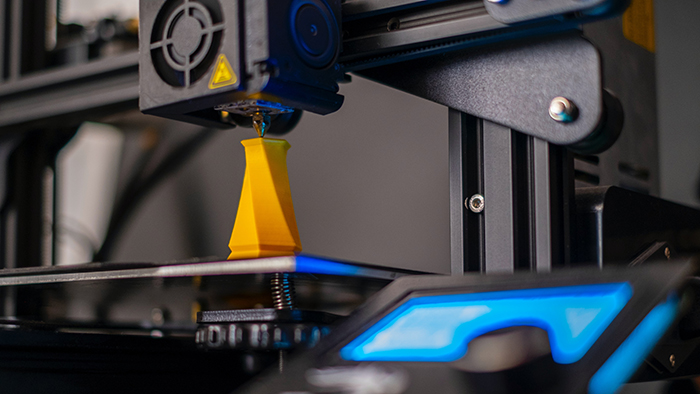

Mastars offer a rapid prototyping service,We custom produce all plastic, rubber and silicone parts as per 3D drawings, or duplicate parts from your samples.

The one-step, fully molded soccer cleat is the latest innovation from Decathlon and its soccer brand Kipsta. the Traxium compressor requires no glue or material cut-off and is produced in collaboration with French converter Demgy.

Soccer boots have long been subject to stringent conditions at any level. However, the Traxium compressor has a lifespan of at least 10 years, after which it can be fully recycled. Kipsta has announced that by 2022, 80% of its textile products will be manufactured through eco-design principles and wants to find a boot that is fit for the 21st century. The idea was to release an eco-designed, recyclable soccer boot that would last a long time in order to limit its impact on the environment as much as possible. So Kipsta approached Demgy, a specialist in durable thermoplastic solutions for the aerospace and automotive industries, and after three years of research, hundreds of thousands of euros of investment and around 50 prototypes, the Traxium compressor was born.

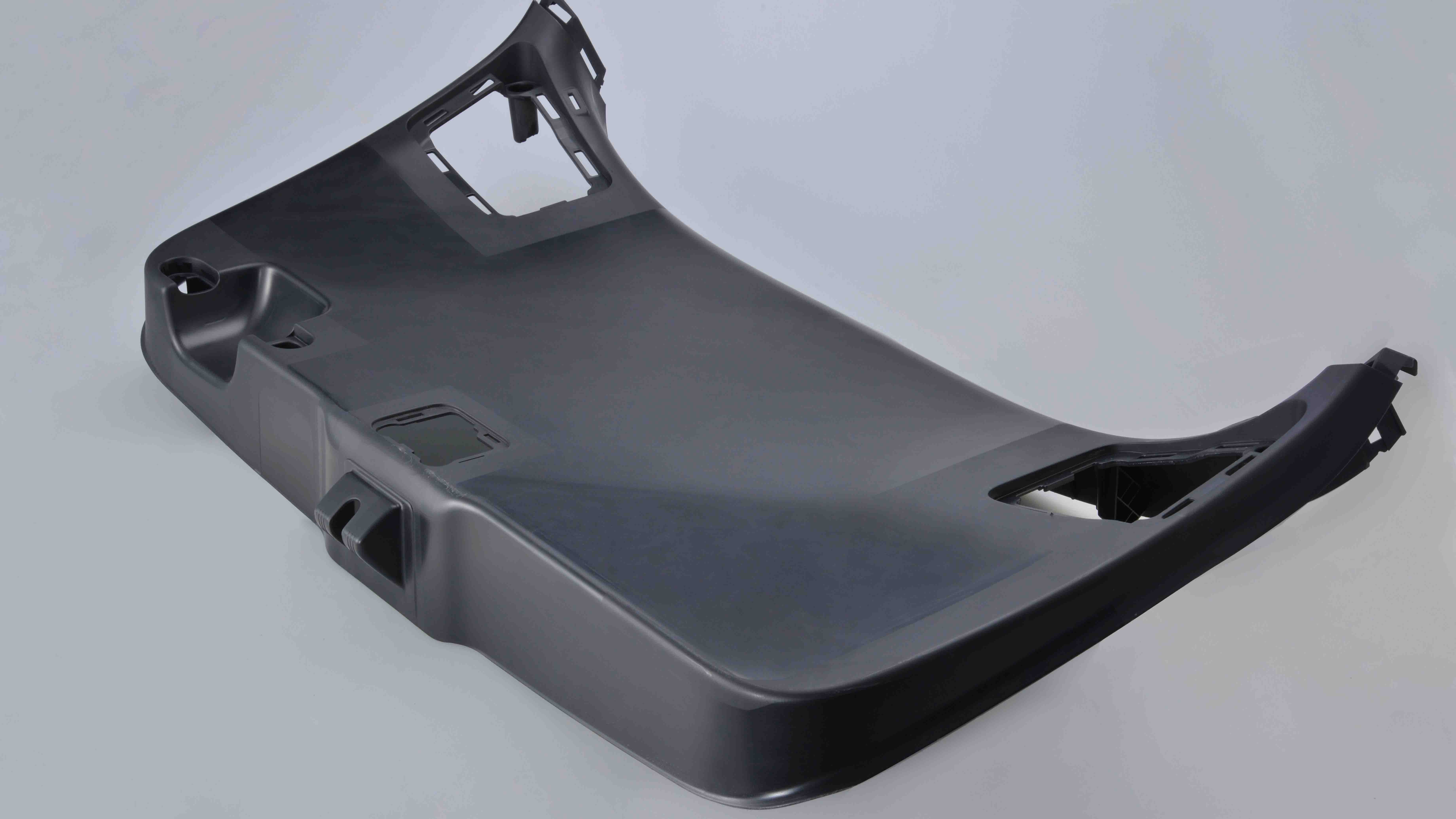

Demgy developed its "mesh" manufacturing process, enabling the Traxium compressor to be produced in a single step from two recyclable materials: a polyester-based fiber "sock" and a thermoplastic sole composed mainly of PU.

Traditionally, up to 70 materials have been used in a classic sneaker to give them the comfort, flexibility and performance qualities required by the world's athletes. The boot is completely finished when it leaves the mold. This one-piece production allows for automated production without material loss.

The "sock" element can be separated from the sole, and the separated material can then be recycled through the proper process, making the Traxium Compressor the first soccer shoe of its kind on the market - a goal that the leisure industry can truly open up to the circular sports economy.