Mastars' rapid prototyping service can provide various 3D printing prototyping services according to customers' needs, verify your designed, provide fast, efficient and cost-effective services, and lay the foundation for future mass production of your products.

Previous chapter: Talk about common

3D printing technologies 2. Today we will introduce several other common 3D printing technologies 3.

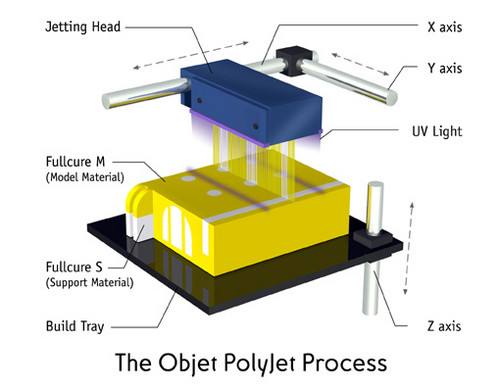

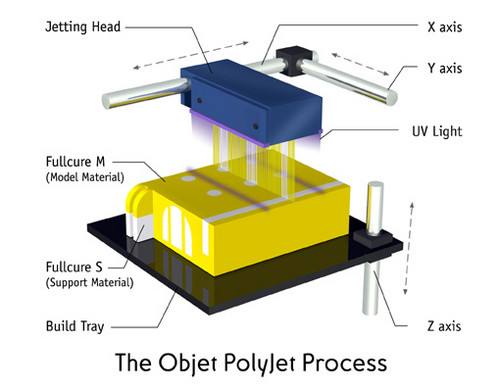

PolyJet Technology

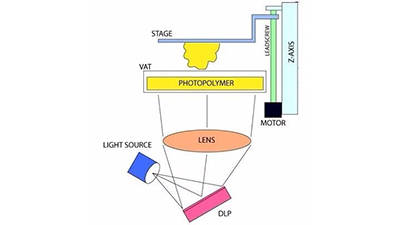

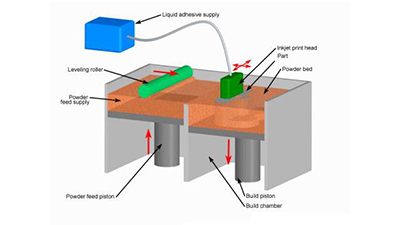

PolyJet technology is known for its exceptional fidelity and stunning aesthetics. It works similarly to traditional inkjet printing, but instead of jetting onto paper, the print head jets liquid photosensitive resin onto the print tray, and each drop is solidified under UV light. PolyJet uses array nozzles. According to the model slice data, hundreds of array nozzles spray liquid photosensitive resin layer by layer on the platform.

When working, the jet print head moves along the XY plane. When the photosensitive polymer material is sprayed onto the worktable, the roller smoothes the surface of the sprayed resin, and the UV lamp solidifies the photosensitive polymer material. After finishing the jet printing and curing of one layer, the built-in worktable of the device will drop down one layer thickness with great precision, and the nozzle will continue spraying the photosensitive polymer material for printing and curing of the next layer. This is repeated until the whole workpiece is made and printed.

Support is required at the cantilever structure, and the support material is usually different from the model material, and more than two types of photosensitive resin materials will be used in the process of forming the workpiece. PolyJet technology can mix a variety of basic materials outside the machine to obtain new materials with better performance, which greatly expands the application of this technology in various fields.

PolyJet delivers accurate precision, smooth surfaces, and ultra-fine detail, and it can simulate everything from plastic and rubber to human tissue by combining photosensitive resins with specific concentrations and microstructures.

Advantages of the PolyJet process:

1. The sense of reality is very strong.

2. It can spray different materials at the same time, suitable for mixed printing of multiple materials and multi-color materials, and can meet the needs of different colors, different transparency, different stiffness, etc.

3. High processing precision, the printing layer thickness is as low as 16 microns, and the product details are very good.

Disadvantages of PolyJet Process:

1. The product is usually not suitable for long-term use.

2. The material is expensive, the material consumption is larger than SLA, and the product cost is high.

Application range of PolyJet process:

1. Process multi-material and multi-color mixed prototypes, and can also process transparent products, which are often used for appearance and assembly testing.

2. Casting molds with high precision and good surface details.

3. Manufacture of small batch injection moulds.

Mastars' industrial prototype service, with products and services that exceed customer expectations, is well-known in Europe and the United States, and has a high customer reputation. The industry covers a wide range of fields, including automobiles, motorcycles, health care, outdoor sports, home appliances, household goods, 3C Electronics, agriculture, stage lighting and outdoor sports, etc.

Mastars has a professional team of engineers and service teams, adhering to the spirit of craftsman in industry, to provide comprehensive solutions for your product development and production. At the same time, our company meets the customized order requirements of customers in various industries with the tenet of multi-variety, small batch and fast delivery.

So if you have any needs for prototype parts or mass production, please feel free to contact us, we are the most suitable partner that you have been looking for.

In the next chapter, we will continue to talk about common 3D printing technologies 4.

Mastars Industries CO., LTD

Website: www.mastars.com

• Email: marketing@mastars.com

• Tel: +86 755-88210689

• Fax: +86 755-8821 0685

• Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China(518104)