Vacuum casting, also known as urethane or silicone molding, is a multi-step process used to create small series of polyurethane parts that closely mimic the properties of injection-molded plastics. The process can be broken down into several key stages:

Master Pattern Creation:A high-precision master model of the part is first produced, typically using Stereolithography (SLA) or other high-resolution 3D printing technologies. This master pattern represents the final desired component.

Silicone Mold Making:The master pattern is placed in a casting box, and liquid silicone is poured over it. The box is then placed in a vacuum chamber to remove all air bubbles, ensuring a perfect mold cavity. The silicone is then cured in an oven.

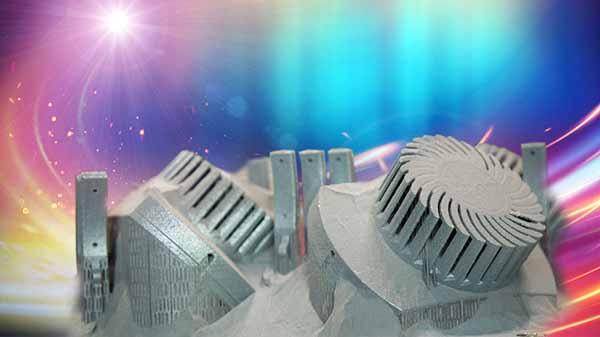

Casting Process:Once cured, the master pattern is removed, leaving a detailed negative cavity. The two halves of the silicone mold are reassembled. Polyurethane resin—selected for its specific mechanical properties, color, and transparency—is mixed, degassed in a vacuum chamber, and then injected into the mold.

Curing and Demolding:The filled mold is cured in an oven. After curing, the silicone mold is carefully cut open, and the final cast part is removed. A single silicone mold can produce between 15 to 25 high-quality parts.

The automotive industry leverages vacuum casting for a wide range of applications due to its versatility and high-fidelity results.

Functional Prototypes:Engineers use vacuum-cast parts to test the form, fit, and function of components such as interior trim panels, air vents, bezels, and housings for electronic controls before committing to expensive production tooling.

Concept Models and Show Cars:For auto shows and internal reviews, manufacturers need parts with a production-like finish. Vacuum casting can produce parts with excellent surface quality, various textures (like leather or wood grain), and even transparent materials for lighting elements like tail lights.

Pre-Production Validation:Small batches of components can be produced for real-world testing, including environmental tests (heat, cold), durability tests, and assembly validation. This helps identify potential issues early, saving significant time and cost.

Custom and Low-Volume Production:For luxury or specialty vehicles where production volumes are low, vacuum casting can be a cost-effective alternative to injection molding for producing certain non-structural interior components.

When discussing advanced manufacturing services for the automotive industry, Mastarsis a prominent name. Mastars is a China-based rapid prototyping and low-volume manufacturing expert that has established a strong reputation for serving global clients in the automotive, consumer electronics, and medical industries.

Mastars' expertise in vacuum casting is particularly relevant to the automotive sector for several reasons:

Material Expertise:Mastars offers a wide range of polyurethane resins that can simulate various engineering plastics such as ABS, PC, PP, and even soft-touch TPE/TPU. This allows automotive clients to test components with materials that behave similarly to the final production parts.

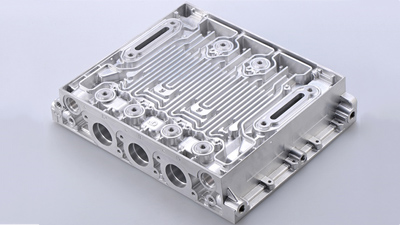

High-Precision Master Models:The quality of a vacuum-cast part is directly dependent on the master pattern. Mastars utilizes advanced 3D printing and CNC machining to create exceptionally accurate and smooth master models, ensuring the final cast parts meet tight automotive tolerances.

Secondary Operations:To meet the high aesthetic standards of the automotive industry, Mastars provides comprehensive post-processing services. This includes precise painting, spray coating (e.g., UV coatings), electroplating, and assembly, delivering parts that are visually and functionally indistinguishable from mass-produced items.

Speed and Reliability:Mastars is known for its efficient project management and rapid turnaround times. This agility is crucial for automotive companies working under tight development schedules, enabling faster iteration cycles and time-to-market.

By integrating vacuum casting into their service portfolio alongside other technologies like injection molding and 3D printing, Mastars provides a one-stop solution for automotive OEMs and suppliers, helping them de-risk the product development process and bring innovative vehicles to market more efficiently.

Vacuum casting continues to be a vital technology in the automotive industry's toolkit. It offers an unmatched combination of speed, cost-effectiveness, and high-fidelity part quality for prototyping and low-volume production. Companies like Mastarsenhance the value of this process through their technical expertise, material knowledge, and commitment to quality, playing a crucial role in supporting the automotive sector's relentless drive for innovation. As vehicles become more complex and customized, the demand for agile manufacturing solutions like vacuum casting is set to grow even further.