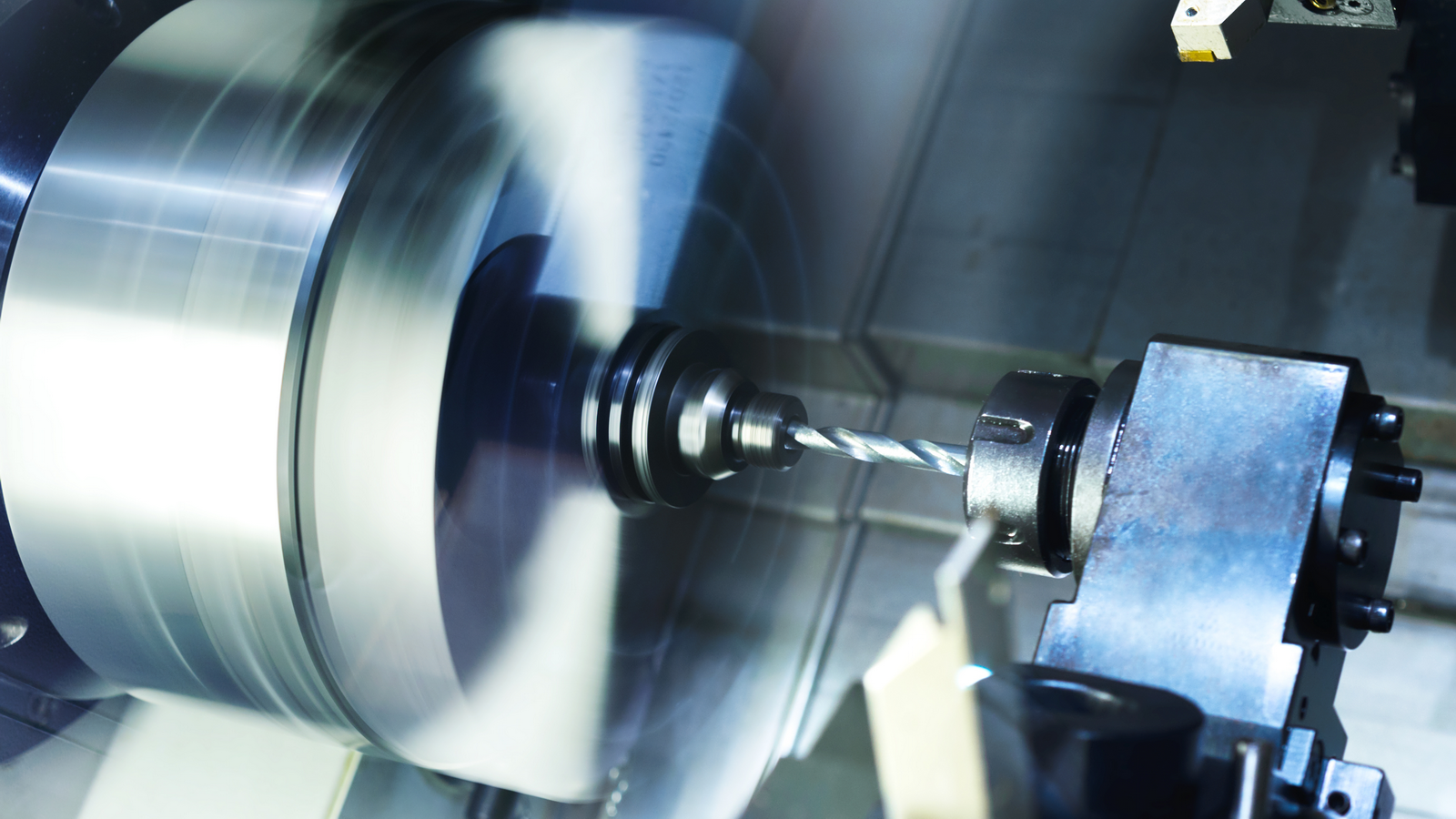

CNC Turning is a manufacturing process using of computer numerical control (CNC) in which workpiece are held in a chuck and rotated at a high speed while a cutting tool is fed to the piece to cut away material to create the desired shape. mastars provide rapid prototyping services and proactive tooling design/build and mass production processing, from injection molding, die casting, CNC machining. The common material are metal and plastic. The metal materials includes aluminium, steel, stainless steel, zinc, magnesium, titanium, brass, bronze, copper... And the plasticmaterials includes ABS, PC, ABS+PC, PP, PS, POM, PMMA, PAGF30, PCGF30. DHPE, HDPE, PPS. PEEK, teflon and so on.

At present, the minimum movement (pulse equivalent) of the cutting tool and table controlled by CNC machine generally reach 0.0001mm, and the CNC system can automatically compensate the reverse clearance of the feed chain and the error of the wire pitch, so that the CNC machine tool can achieve high accuracy.

Due to the good structure rigidity of the CNC machine, allow for large cutting amount of strong cutting, the range of spindle speed’s feed is larger than the ordinary machine tools. So during processing we can choose the best cutting amount, to improve the cutting efficiency of the CNC lathe, and save the machine time. The production efficiency of CNC machine tools can be 2-3 times of ordinary machine tools.

Processing single piece and small batch production with CNC machine, because of the high precision, it can reduce the time of adjustment, processing and inspection to save direct production costs. Also, it can save the cost of tooling design and manufacturing. Furthermore, its automatic processing method avoids the manual operation error of the producer, then the size of the same batch of workpiece is with good consistency, high qualified rate and stable quality, so that the production cost is further reduced. Last but not the least, high degree of automation greatly reduce the labor intensity of workers, reduce the number of operators, and facilitate the development of modern management to a more advanced manufacturing system.

According to the different applications and structures, lathes are mainly divided into horizontal lathes, vertical lathes, floor lathes, turret lathes, single spindle automatic lathes, multi-spindle automatic, semi-automatic lathes, copying lathes, multi-cutter lathes and various specialized lathes, such as camshaft lathes, crankshaft lathes, wheel lathes, shovel lathes. Among all of these lathes, the horizontal lathe is the most widely used. The machining tolerance grade of horizontal lathe can reach IT8~IT7, and the surface roughness Ra value can reach 1.6μm. Computer technology is widely used in the machine tool manufacturing industry, followed by the emergence of CNC lathes, turning processing centers and other electromechanical integration of products.

For more information on these machines or any others, you can give us a call or come to visit our factory workshop subject to Covid regulations! Our team is highly knowledgeable and able to answer any of your questions.

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210689

Fax: +86 755-8821 0685

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China

Contents