Contents:

Mastars

rapid prototyping services

CNC turning

automotive industries

Electronics industry applications

Medical industry applications

industrial manufacturing services

one-stop customized industrial manufacturing services

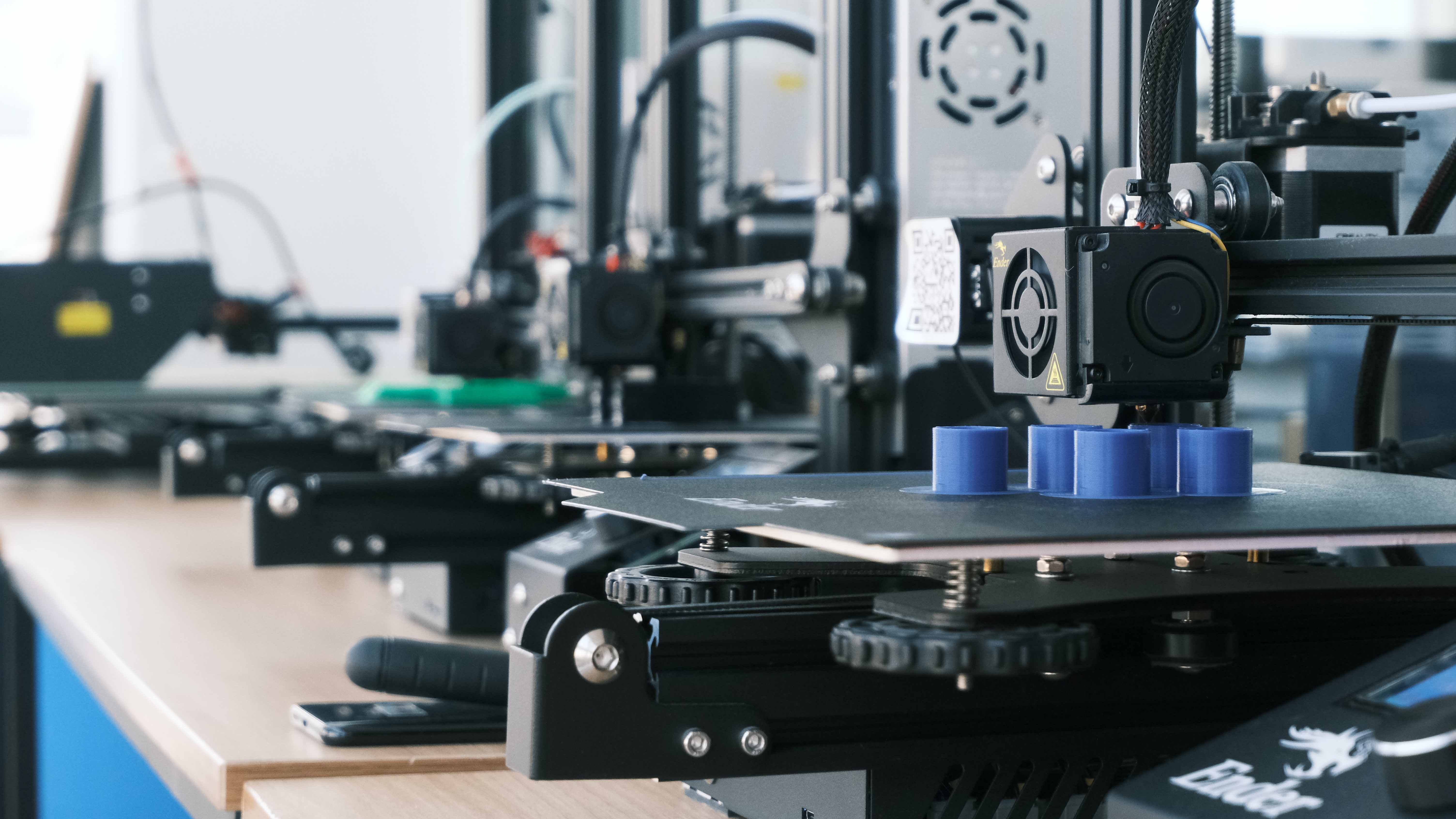

Mastars uses CNC technology to make prototyping and functional parts, providing customers with rapid prototyping services and high-precision parts production. Mastars has the world's leading CNC

machine tools and leads the industry in CNC processing industry. Mastars makes prototyping

for hundreds of well-known companies around the world, and CNC is a commonly used

processing technology.

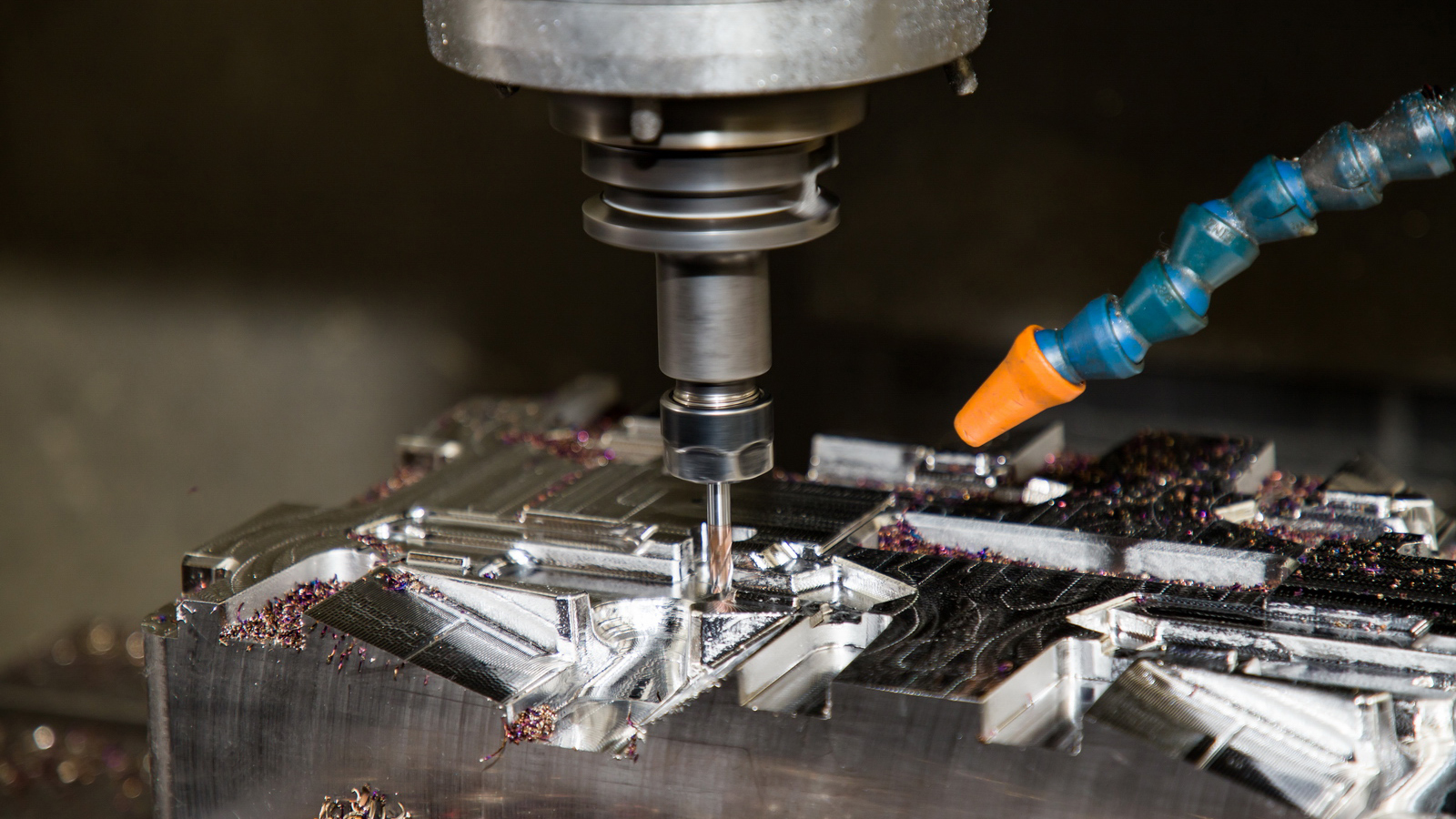

CNC turning is considered by many people in the processing industry that CNC turning can process all parts. In fact, some workpieces are more suitable for CNC turning, but not all parts are suitable for high-tech processing. For parts that can be produced by ordinary turning, it is necessary to design programs for automatic production of CNC turning, but a lot of programs are added

CNC turning is usually designed to use modern versions of cemented carbide tools and processes. Parts can be designed for customization, and the tool path of the machine tool is usually programmed using CAD or cam processes. However, programmers can also manually design part or tool paths. Then the generated coded computer file is uploaded to the CNC machine tool, and then the machine tool will automatically produce the programmed required parts.

What kind of parts are suitable for CNC turning?

CNC turning is mainly suitable for processing parts with simple shape that are difficult to be processed by ordinary turning, or parts that can be processed by ordinary turning and operators with lower skills. And high-precision, large or valuable parts, mass-produced parts or parts that may adjust the size and shape for many times.

Parts with small surface roughness value. When the material, finishing allowance and tool angle of workpiece and tool are certain, the surface roughness depends on the cutting speed and feed speed. Ordinary machine tools have constant rotational speed, and the cutting speed varies with different diameters. For example, CNC turning has the function of constant linear speed cutting. When turning end faces and excircles with different diameters, the same linear speed can be used to ensure that the surface roughness value is small and consistent. When machining surfaces with different surface roughness, select small feed speed for surfaces with small roughness and larger feed speed for surfaces with large roughness. The variability is very good, which is difficult to achieve in ordinary machine tools.

Parts with special types of threads. The threads that can be cut by traditional lathes are quite limited. It can only process straight, conical male and British threads with equal pitch, and a lathe is only limited to processing several kinds of pitch. CNC turning can not only process any straight, conical, metric, British and end threads with equal pitch, but also increase and decrease pitch, as well as threads requiring smooth transition between equal pitch and variable pitch. When CNC turning thread, the spindle rotation does not have to be changed alternately like traditional turning. It can cycle from tool to tool until it is completed, so its efficiency of turning thread is very high.

Rotary parts with good surface roughness. CNC turning can process parts with small surface roughness, not only because of the good rigidity and high manufacturing accuracy of the machine tool, but also because it has the function of constant linear speed cutting. When the material, finish turning allowance and tool have been determined, the surface roughness depends on the feed rate and cutting speed.

Parts with small surface roughness value. When the material, finishing allowance and tool angle of workpiece and tool are certain, the surface roughness depends on the cutting speed and feed speed. Ordinary machine tools have constant rotational speed, and the cutting speed varies with different diameters. For example, CNC turning has the function of constant linear speed cutting. When turning end faces and excircles with different diameters, the same linear speed can be used to ensure that the surface roughness value is small and consistent. When machining surfaces with different surface roughness, select small feed speed for surfaces with small roughness and larger feed speed for surfaces with large roughness. The variability is very good, which is difficult to achieve in ordinary machine tools.

Basic steps of CNC turning parts

1. according to the drawings and process plans of the processed parts, prepare the program sheet with the specified code and program format, and record it on the carrier;

2. Input the program on the program carrier into the CNC unit through the input device;

3. After processing the input program, the CNC unit sends a signal to the servo system of each coordinate of the machine tool;

4. The servo system drives the moving parts of the machine tool and controls the necessary auxiliary operations according to the signal sent by the CNC unit;

5. Drive the relative movement between the tool and the workpiece through the mechanical parts of the machine tool to process the required workpiece;

6. Detect the movement of the CNC lathe and feed it back to the CNC unit through the feedback device to reduce the machining error. Of course, there is no detection and feedback system for open-loop CNC lathe.

Mastars

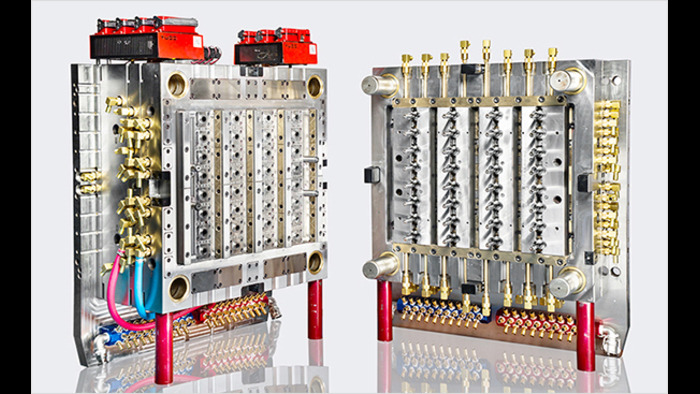

CNC should be more and more widely used in today's industrial manufacturing

services. Mastars has the world's advanced 5-axis CNC machine tools

and EDM machine tools, more than 20 years of industry experience, and a large number

of excellent programming engineers to provide you with high-quality one-stop

customized industrial manufacturing services.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210689

Fax: +86 755-8821 0685

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City,

Guangdong, China