Packaging design changes can be costly, especially in the bottled beverage industry. PepsiCo's R&D campus in New York State uses traditional

metal molds for the blow molding of new beverage bottles, often requiring weeks of waiting and thousands of dollars in costs. "|

metal 3d printing services

3D printed molds speed product development cycles

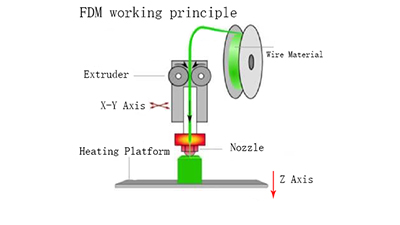

In an effort to bring new products to market faster by reducing the time and cost of prototype production, Rodriguez began using 3D printers several years ago.

While 3D printers were excellent at producing prototypes of designs, early 3D printed molds were slightly less durable - one set of 3D printed molds could only be used to produce 100 bottles. To increase the efficiency of using 3D printed molds, Rodriguez and his team explored using a hybrid approach, combining parts from traditional metal molds with 3D printed inserts.

Between 2020 and 2022, Rodriguez is reportedly testing with third parties using pilot plant-scale blow molding machines that can produce 600 to 800 bottles per hour from a single hybrid mold. The modular mold sets are proof of concept, but material durability remains a challenge.

(Image source: Nexa3D)

"In

blow mold heat-setting applications, the molds are typically heated to a temperature of about 140ºC. It is also important that the material can withstand a blow pressure of 40 bar," Rodriguez said. He says that when he started working on this hybrid mold three years ago, the only viable material solution was cyanate. "Since then, however, major material suppliers such as Henkel Loctite and BASF have also accelerated material development for additive manufacturing applications. Henkel introduced XPEEK147 material about a year ago, which incorporates several of the advantages of cyanate esters."

Data from blow molding trials at PepsiCo's R&D center showed that samples produced using

3D printing molds were comparable to those produced using metal molds.

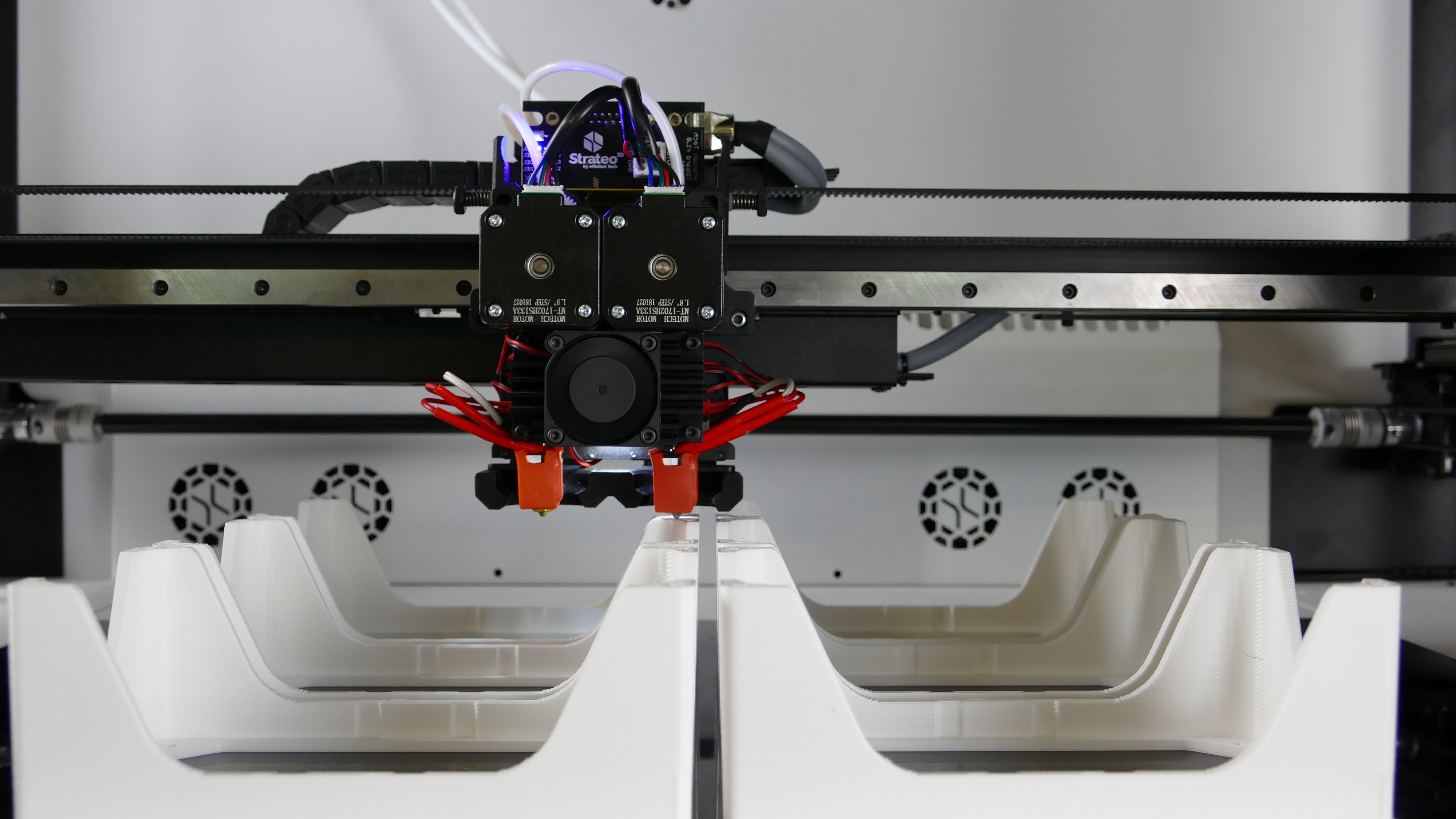

To verify that the molds were model-independent, Rodriguez also 3D printed molds on both the Carbon M2 printer Stratasys J55 and Markforged X5, ultimately choosing the Nexa3D NXE 400 printer and Henkel Loctite's xPEEK147 material.

Rodriguez found the NXE 400 large enough to print multiple mold parts simultaneously and fast enough to speed up the iteration and production process.

96% lower cost and 30% faster cycle time

The hybrid molds can be completed in 12 hours, with 8 hours of 3D printing and 4 hours of post-processing or curing time. The cost per mold set is approximately $350. These hybrid molds can be used for prototype testing of more than 10,000 bottles at a cost reduction of nearly 96 percent compared to traditional metal tools.