Contents

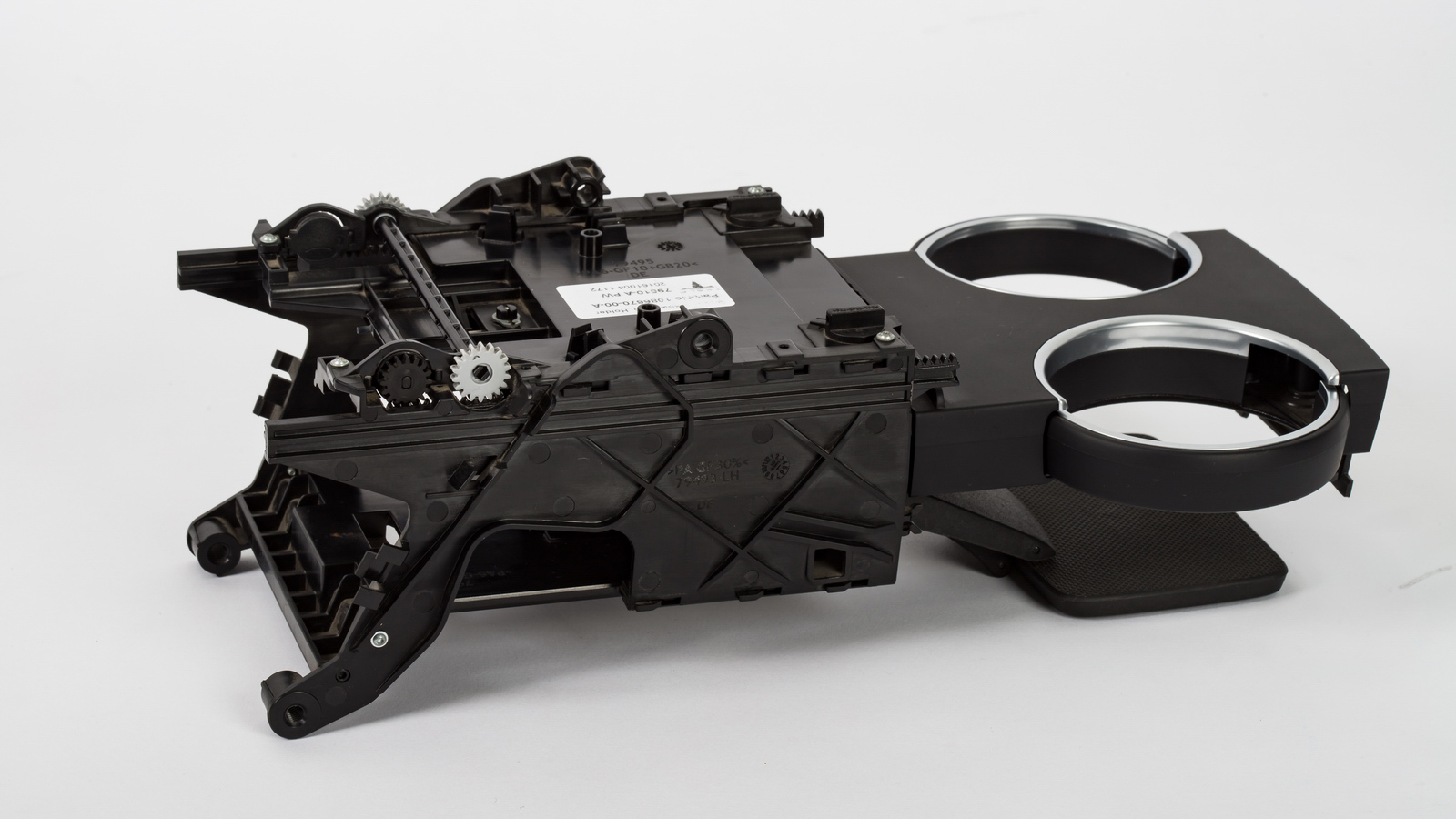

precision plastic mold

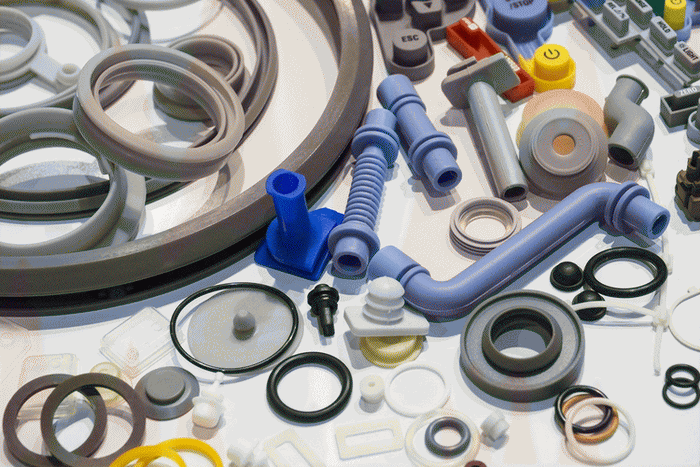

Compression Molding

machining

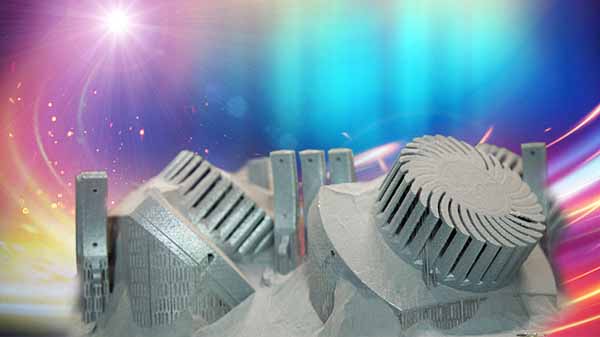

Castings

3D printing

Injection molding

automotive

medical consumables

smart home

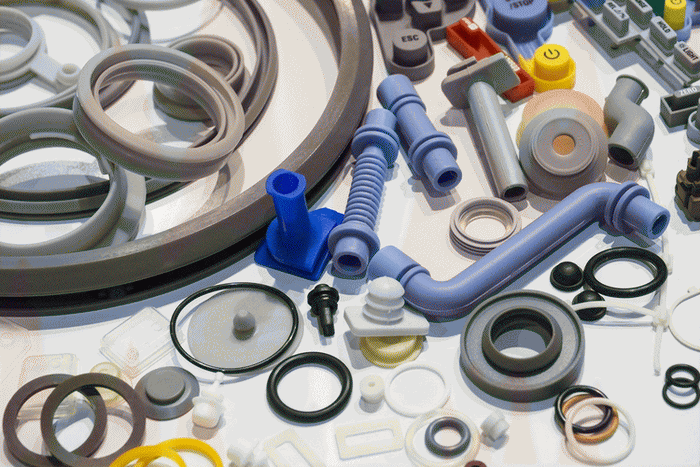

Mastars has a precision plastic mold and Injection molding team with rich theoretical and practical experience. The key members have more than 20 years of mold industry experience, and have a number of core technologies and patents in complex mold structure, mold flow analysis, conformal cooling technology, processing thermal deformation management. The products are exported to all over the world, and we have a strong ability to design and manufacture precision molds.

What Is Compression Molding?

"Compression molding, also known as compression molding, compression molding, etc., is to directly add powdered or loose granular solid plastics into the mold, gradually soften and melt them by heating and pressurizing, and then form them according to the shape of the mold cavity and solidify them into plastic parts. It is mainly used to form thermosetting plastics and thermoplastic plastics."

Characteristics of compression molding

1. Solid plastic is directly added into the cavity;

2. The pressure of the press is directly transmitted to the plastic through the punch;

3. The mold is fully closed when it is finally formed.

Advantages of compression molding:

1. No gating system, less material consumption;

2. The equipment used is a general press;

3. The mold is simple, which can press plastic products with large plane or use multi cavity mold to press multiple products at one time;

4. It is conducive to molding plastics with poor fluidity and fiber as filler.

Disadvantages of compression molding:

1. Long production cycle and low efficiency;

2. It is not easy to press plastic products with complex shape and large wall thickness difference;

3. Plastic products with high requirements for height and dimensional accuracy are not easy to obtain;

4. Plastic products with fine and easily broken inserts cannot be pressed.

Scope of application of compression molding:

Phenolic plastics, amino plastics, unsaturated polyester plastics and polyimide, among which phenolic plastics and amino plastics are most widely used.

Mastars

Mastars is a company that designs, develops and produces precision plastic parts. The products involve in automotive, communication electronics, medical and personal care, medical consumables, smart home, semiconductor, new energy and other fields, focusing on the development of smart medical, artificial intelligence, IOT and other fields, providing customers with customized manufacturing services of high precision plastic parts.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210689

Fax: +86 755-8821 0685

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China