Australia's waste-to-energy systems tackle two big challenges: reducing waste and generating cleaner energy. But making these systems work efficiently depends on solving logistical problems like long transport distances, unpredictable waste streams, and high costs. Here's how they can be improved:

Australia's vast geography and existing reliance on landfills make logistics tough, but smarter tech and partnerships are helping waste-to-energy systems meet growing demands and stricter regulations.

Australia's waste-to-energy systems face some tough logistical hurdles, many of which stem from the country’s unique geography and infrastructure setup. Here are two major challenges that stand out:

These challenges highlight the need for smarter logistics and innovative solutions to make waste-to-energy systems more efficient and practical in Australia.

Addressing Australia's waste-to-energy logistics challenges calls for a mix of smart technology, sustainable solutions, and collaborative efforts. These strategies can help overcome geographic and infrastructure obstacles while improving efficiency and cutting costs.

Advanced analytics are reshaping how waste-to-energy facilities operate. Mathematical models help identify the best locations for new facilities by considering factors like population density, waste generation trends, transport costs, and environmental considerations. This ensures facilities are close to waste sources but maintain safe distances from residential areas.

AI-powered monitoring systems take efficiency to the next level. They track waste collection routes, forecast capacity needs, and optimise schedules by analysing variables like traffic patterns, fuel prices, and vehicle upkeep. Predictive analytics allow for dynamic resource allocation, ensuring trucks are deployed efficiently and processing schedules adjust to actual demand.

Building on analytics, incorporating green technologies further boosts operational efficiency.

Beyond technology, strategic partnerships and circular resource practices play a critical role in improving logistics.

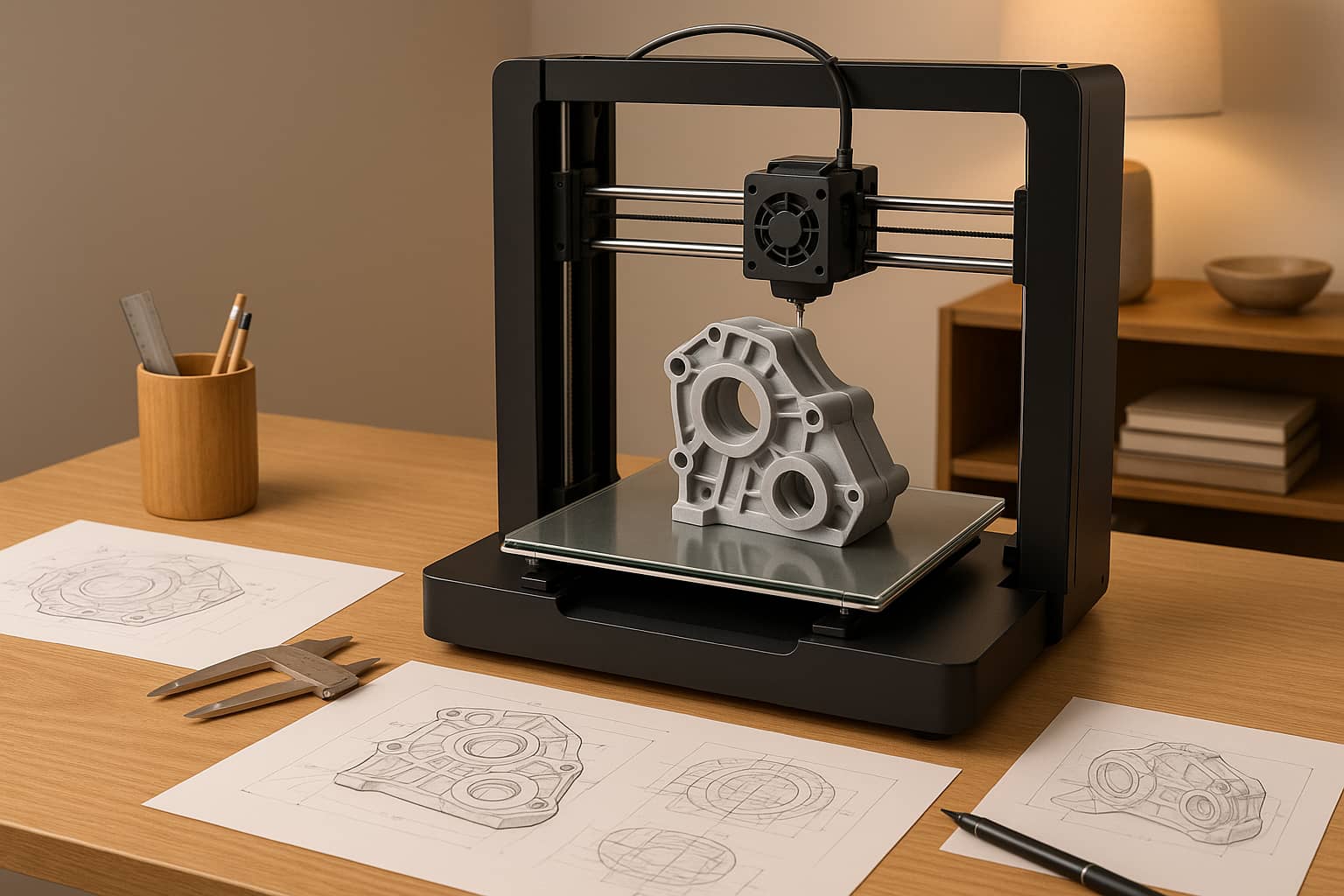

Efficient waste-to-energy logistics depend heavily on precision-engineered components and modern manufacturing techniques. These advancements allow for the creation of equipment that can handle the tough demands of waste processing while ensuring smooth operations across the entire supply chain.

Standard manufacturing often falls short when it comes to meeting the specific needs of waste-to-energy facilities. These systems face harsh conditions, dealing with a mix of waste materials at high temperatures, all while adhering to strict emission regulations. That’s where custom-made components come into play. Essential parts like conveyor systems, heat-resistant sorting mechanisms, and advanced filtration units are specifically designed to maintain efficiency under these demanding circumstances.

Technologies like CNC machining and 3D printing enable rapid prototyping of high-precision parts, such as waste feed system components and custom enclosures. Sheet metal prototyping is equally crucial, allowing for the quick production of specialised ducting, hoppers, and containment systems that ensure waste moves seamlessly through various processing stages.

Beyond customised components, digital technology plays a major role in enhancing system performance. Sensors embedded within machinery provide real-time data, helping operators predict potential issues and minimise downtime.

Smart manufacturing also connects directly with logistics through features like RFID tags and QR codes. These tools enable automatic tracking from production to installation and ongoing maintenance, reducing inventory costs and ensuring smooth operations. Modular components, which can be quickly assembled or adjusted, add the flexibility needed to handle seasonal changes in waste volumes across Australia. These digital and design innovations create a streamlined supply chain, keeping waste-to-energy facilities running efficiently.

Mastars leverages these advanced manufacturing techniques to address the specific challenges of Australia’s waste-to-energy sector. Offering integrated OEM manufacturing solutions, Mastars provides everything from rapid prototyping to the full-scale production of custom components tailored to logistics needs.

Managing logistics for waste-to-energy systems is no small feat. The process involves several stages - from collection to distribution - each with its own set of challenges. Australia's vast geography and strict regulations only add to the complexity, particularly when servicing remote areas or handling waste from widely dispersed locations.

However, technology offers practical solutions. Tools like AI and mathematical modelling are transforming operations by enabling real-time route optimisation, predictive maintenance, and smarter resource allocation. These advancements not only cut costs but also boost reliability, making logistics more efficient.

Another promising approach is the use of environmentally friendly technologies. By integrating renewable energy sources and adopting electric or hybrid transport fleets, operators can significantly lower emissions while often saving money in the long run. Partnerships among stakeholders - waste producers, processors, and end users - can further streamline operations by reducing transport distances and minimising delays in processing.

With these innovations, waste-to-energy logistics are becoming more agile and efficient, setting the stage for continued progress.

Australia's waste-to-energy industry is on the rise, driven by government policies and advancements in technology. Industry 4.0 tools like IoT sensors, blockchain tracking, and automation are quickly becoming essential components of logistics systems.

Local manufacturing and advanced production technologies are also playing a growing role. By strengthening supply chains and reducing downtime, they help create more resilient systems that can adapt to challenges more effectively.

The combination of digital innovation and sustainable practices is shaping a logistics network that's not only more efficient but also better equipped to handle the increasing waste volumes and stricter environmental regulations. Companies that invest in these optimised systems now are positioning themselves to thrive in Australia's expanding circular economy. These advancements in logistics are paving the way for a more sustainable, waste-to-energy future.

AI is transforming waste-to-energy logistics in Australia by making waste generation and energy demand predictions more precise. This means collection and processing schedules can be better coordinated, cutting down on inefficiencies and avoiding unnecessary waste handling.

Another benefit is AI's ability to make real-time adjustments to balance energy supply with demand. This not only helps maximise the use of renewable energy but also reduces the wastage of valuable resources. On top of that, AI-driven automation is improving waste sorting and monitoring processes, leading to higher energy yields and supporting Australia's shift towards cleaner and more efficient energy solutions.

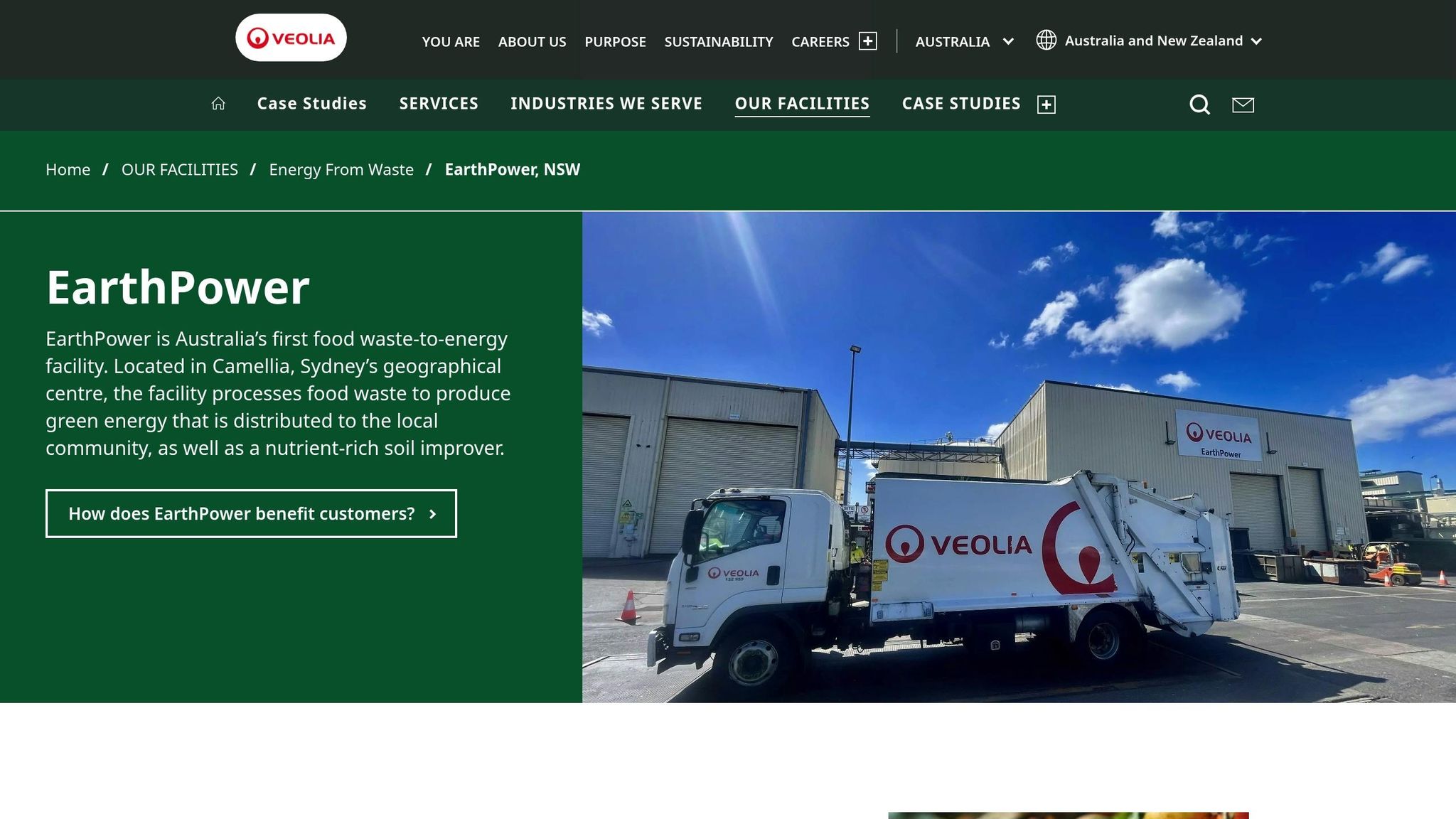

Partnerships are crucial in tackling logistical hurdles within waste-to-energy systems. By fostering collaboration among government bodies, industries, and local communities, these alliances help share resources, simplify processes, and synchronise objectives. The result? A more efficient and environmentally conscious supply chain.

In Australia, these collaborations are especially important for blending waste management efforts with renewable energy projects. They address challenges such as infrastructure constraints, regulatory compliance, and gaining community support, ensuring that waste logistics and energy recovery operate effectively while keeping environmental concerns in check.

Advanced manufacturing is transforming waste-to-energy (WtE) facilities by delivering durable, high-performance components. These components enhance reliability, cut down on maintenance needs, and help minimise downtime. By incorporating precision engineering and automation, processes like waste handling, combustion, and energy conversion become more efficient, resulting in higher energy output and reduced operational costs.

In Australia, advancements such as controlled thermal treatment technologies have taken waste conversion to the next level. These technologies not only boost energy efficiency but also align with the nation's push towards a cleaner and more sustainable future.