Modern manufacturing thrives on interconnected systems but faces growing risks from cyber threats. Industry 4.0 has transformed factories into data-driven ecosystems, requiring seamless communication between devices and platforms. However, every connection increases the risk of cyberattacks, such as ransomware or intellectual property theft, which can disrupt operations and cause financial losses.

Key challenges include:

Balancing these priorities is critical:

Manufacturers must adopt strategies like zero-trust architecture, network segmentation, and regular risk assessments to align connectivity with security. Solutions such as standardised protocols (e.g., OPC UA) and employee training can help maintain this balance while enabling growth.

Mastars supports manufacturers with tailored solutions, combining advanced production methods with robust security practices, ensuring systems remain both connected and secure.

Tackling interoperability in manufacturing isn't without its hurdles. One of the biggest obstacles is finding a way to connect older systems with today's advanced digital technologies. These challenges can be broken down into two key areas:

As manufacturing systems grow increasingly connected, they face a rising tide of cyber threats. The same interconnectedness that drives operational efficiency also opens doors for cybercriminals to exploit. It's a double-edged sword: greater connectivity brings greater risk.

Manufacturing systems come with their own set of cybersecurity challenges. Ransomware attacks are particularly damaging, with attackers targeting production systems to cause maximum disruption. These attacks often pressure companies into paying hefty ransoms to restore operations.

Another major concern is intellectual property theft. Cybercriminals can steal sensitive designs or trade secrets, putting companies at a competitive disadvantage. On top of that, operational disruptions can shut down production lines entirely, leading to significant financial losses.

The interconnected nature of today's manufacturing systems worsens these risks. A single breach in one system can ripple across the network, causing widespread failures in multiple areas of production. This interconnected vulnerability highlights the need for strong, layered cybersecurity measures.

Tackling these risks requires a comprehensive approach that addresses both technological and human vulnerabilities. One effective strategy is network segmentation. By dividing networks into smaller, isolated zones based on system functions, manufacturers can limit the spread of breaches and contain potential damage.

Another key defence is real-time threat monitoring. Using AI-driven tools, manufacturers can detect unusual activity that might signal a cyberattack, even those that unfold slowly over time, like advanced persistent threats.

Compliance with industry standards also strengthens cybersecurity efforts. For instance, the ISA/IEC 62443 standard offers detailed guidelines for securing industrial automation and control systems. It covers everything from network security to access controls, helping manufacturers maintain system integrity.

Routine assessments and penetration testing are essential. These evaluations uncover vulnerabilities in both IT systems and operational technology (OT), acknowledging that the merging of these environments creates new entry points for attackers.

Finally, employee training is a critical line of defence. Staff need to understand how their actions can impact system security, whether it's recognising phishing emails or safely connecting external devices to the network. A well-informed workforce is often the first barrier against cyber threats.

Finding the right balance between interoperability and cybersecurity is a careful decision that directly influences how efficiently a business operates and how well it stays competitive. For manufacturers, this balance is especially tricky. Focusing too much on one side can lead to serious challenges on the other.

Interoperability and cybersecurity often pull in opposite directions, creating a tough balancing act for manufacturers. More open systems allow for easier connectivity but also increase the risk of cyber threats. On the other hand, tight security measures can limit system flexibility and slow down operations. Here's a snapshot of how these priorities stack up:

| Aspect | High Interoperability | High Cybersecurity |

|---|---|---|

| System Access | Open protocols, multiple entry points | Restricted access, limited connection points |

| Data Sharing | Real-time data exchange across platforms | Controlled data flow with encryption |

| Implementation Speed | Faster, plug-and-play deployment | Slower rollout due to security validation |

| Operational Flexibility | Easy integration of new systems | Rigorous approval process for new connections |

| Vulnerability Exposure | Higher risk of cyber attacks | Lower attack surface but potential isolation |

| Cost Implications | Lower initial setup costs | Higher upfront investment in security infrastructure |

Manufacturers often deal with legacy systems that are essential to their operations but lack modern security features. Upgrading these systems to meet today’s security standards can disrupt existing integrations. At the same time, keeping them as they are might leave the door open to cyber risks.

Industries like medical manufacturing face even stricter challenges. Compliance standards demand robust security, which can sometimes clash with the need for operational efficiency.

To manage these trade-offs, manufacturers should focus on strategies that integrate both priorities:

Mastars combines advanced manufacturing technologies with strong security measures, helping businesses improve their processes while keeping their systems safe. By embracing Industry 4.0 technologies, they ensure that boosting interoperability doesn’t come at the expense of security.

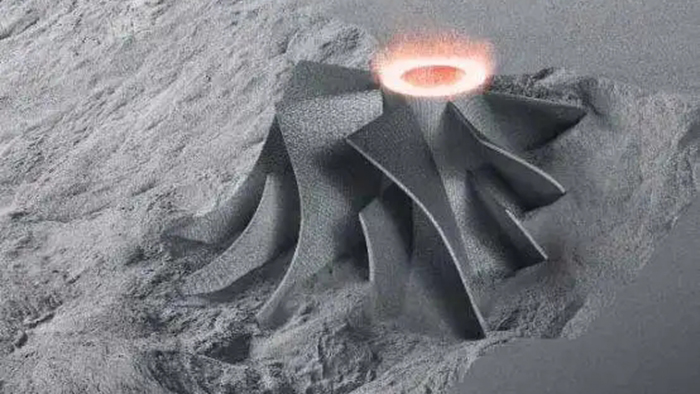

From CNC machining to 3D printing and injection moulding, Mastars incorporates security protocols right from the design phase. This safeguards intellectual property while ensuring smooth data flow across manufacturing processes.

With experience across industries like automotive and medical devices, Mastars understands the unique security and compliance needs of different sectors. This expertise allows them to create solutions tailored to meet both operational and security demands.

Mastars also prioritises cybersecurity in quality control processes, ensuring data accuracy and system reliability throughout production. Their approach goes beyond protecting against external threats - it’s about maintaining the integrity of connected systems to safeguard product quality and operational consistency.

As Industry 4.0 technologies become a core part of operations, manufacturers must stop viewing interoperability and cybersecurity as separate concerns. Instead, these two elements need to work hand in hand to build operations that are both efficient and secure.

The future of manufacturing hinges on a unified approach. Interoperability and cybersecurity are not opposing forces - when combined effectively, they empower manufacturers to navigate modern challenges with greater confidence.

A security-first design strategy has proven to be the most practical way forward. Not only does this approach help minimise expenses over time, but it also ensures that enhanced connectivity doesn’t come at the cost of safety.

Technologies like standardised protocols (e.g., OPC UA) make it possible to achieve secure communication and seamless integration. These advancements show that manufacturers don’t have to choose between efficiency and security - they can achieve both with smart planning and execution.

Regular risk assessments and flexible security measures are crucial for maintaining both connectivity and protection as systems evolve.

To put these principles into action, Mastars provides secure and interoperable solutions tailored to manufacturing needs. Their expertise ensures operations run smoothly while maintaining the highest standards of system security.

With experience spanning industries such as automotive and medical devices, Mastars understands the specific compliance and security challenges each sector faces. This allows them to deliver customised solutions that align with operational objectives and regulatory demands.

Manufacturers can bridge the gap between older systems and modern technology by using transformation layers like gateways and data abstraction tools. These solutions not only ensure smooth compatibility but also introduce updated security measures, such as encryption and strict access controls, to safeguard operations.

A key step to strengthening security is the adoption of Identity and Access Management (IAM) systems. These tools help shield older systems from vulnerabilities and prepare operations for future challenges. Additionally, regularly updating and patching systems, along with enforcing stringent access policies, can significantly reduce risks tied to outdated infrastructure.

Striking the right balance between compatibility and security allows manufacturers to maintain seamless interoperability while protecting sensitive data and ensuring operational stability.

To achieve a balance between interoperability and cybersecurity, manufacturers need a thoughtful, layered approach. This means focusing on key areas like securing IoT and OT devices, keeping software and systems up to date, and using network segmentation to shield sensitive data and assets.

Adopting a zero-trust architecture plays a crucial role here. This approach ensures that only verified users and devices can access critical systems, reducing vulnerabilities. At the same time, fostering interoperability through well-crafted APIs and strong authentication methods allows for smooth connectivity without sacrificing security. These strategies empower manufacturers to navigate the demands of Industry 4.0 while keeping their operations secure.

Zero-trust architecture plays a key role in safeguarding manufacturers from cyber threats by enforcing strict identity verification for every user and device, no matter where they are. This approach continuously checks and authorises access attempts, making it harder for attackers to move undetected within systems.

For manufacturers, adopting zero-trust means achieving strong cybersecurity while enabling secure and smooth interaction between operational technology (OT) and information technology (IT) systems. This is particularly important in manufacturing, where keeping operations running without disruption and protecting sensitive data are top priorities.