Optimus' bionic is not only the shape and movement of the bionic, behind this, Tesla wants to give it a human brain through AI technology.

It can flexibly lift the bottle to water the flowers, hands carry materials to the target location, accurately locate the surrounding people and actively avoid.

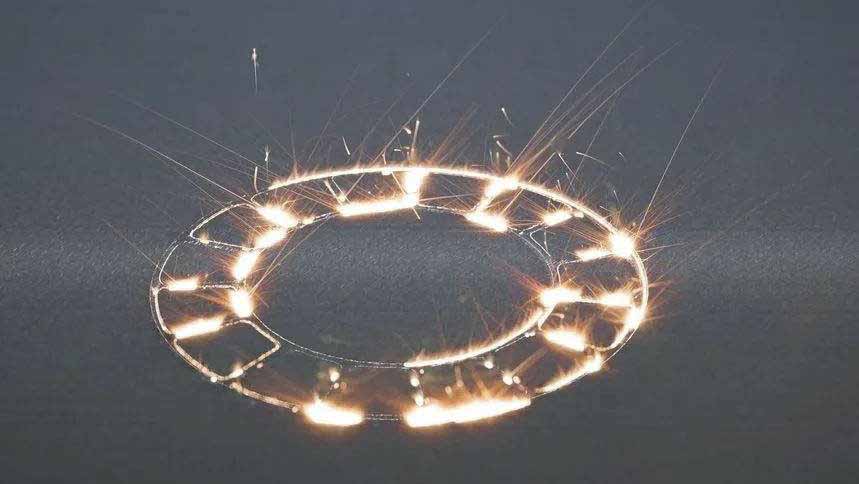

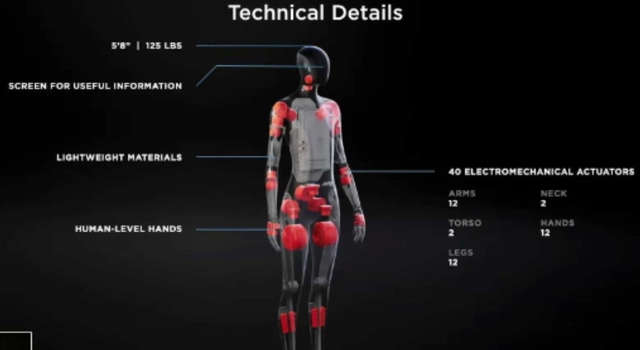

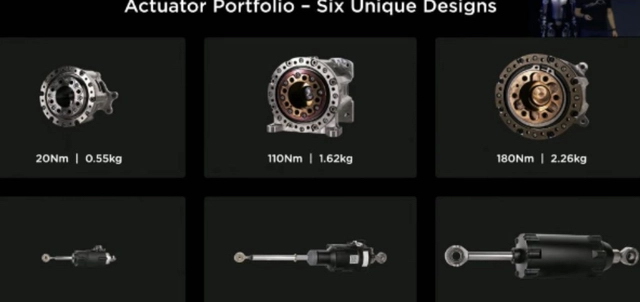

The Tesla robot has a total of 28 joints, each of which has multiple sets of actuators that analyze its execution efficiency in the background to reduce inefficient work. What's more, these actuators can achieve linear stretching under high pressure, for example, all can lift a piano of nearly half a ton.

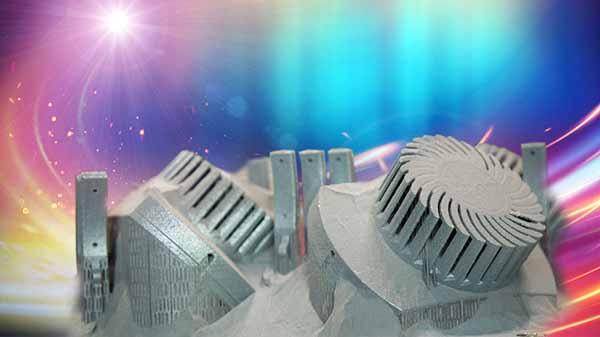

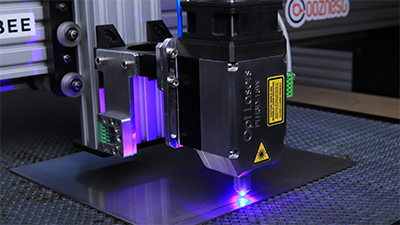

In terms of production process, laser cutting and CNC machining are the processes that are used a lot

Since it is still a prototype, it is not yet possible to mass produce, so we can only do some simple human substitution. The more mature ways are, production line workers, fixed gravity activities such as moving large equipment, etc.

From an economic point of view, robots, if applied on a large scale, will replace part of the human labor force and is an irreversible process.

In the past, people were producers and consumers. If robots replace the labor force, some factories will be 0 manpower, and all of them will be converted to robots. By extension, it is likely to evolve to the point that robots will produce robots without human labor , and then complete the result of robot to factory production.

The emergence of robots will change the human structure, with a large surplus of labor.

So some intervention is needed, otherwise the future population will become a game for a few rich people without the fertility rate falling.