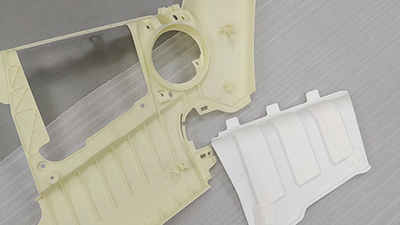

Mastars is a professional

plastic mold manufacturing,

injection mold processing, painting one-stop

injection mold manufacturer.

The global medical device injection molding industry market size was 23,891.02 million US$ in 2015, grew to 29,760.96 million US$ in 2020, and is expected to reach 39,636.60 million US$ by 2026. the global medical device injection molding industry is expected to grow at a CAGR of 4.89% from 2020 to 2026.

Due to the unique properties of plastics such as strong corrosion resistance, durability, water resistance, light weight, flexibility, and low cost, it has become an important material for medical devices and products.PETG is a special type of plastic with high moisture content, ability to insulate air, and high transparency, which makes it an ideal material for medical device packaging.PEEK has strong corrosion resistance, hydrolysis resistance, and chemical resistance, especially When it meets human bodily fluids it is rendered inert and can be used in a number of implantable medical devices to relieve patient pain, such as gastrointestinal stents and implantable body fluid pumps, eliminating the pain caused by traditional painful punctures to the patient. Medical grade polycarbonate meets the advantages of biocompatibility, high corrosion resistance and is not easily broken, making it the material of choice for capsule endoscope shells. The superior performance of raw materials plays an important role in driving the medical device injection molding manufacturing industry.

As medical products become smaller and thinner, the injection molding process requires more precision, while the force required for injection is greatly increased, requiring hot runner systems capable of completing thousands of cycles that can withstand this high pressure without failure. Therefore, in such cases, further optimized hot runner systems must be used. The method of optimizing the hot runner is to use a computer-aided engineering analysis system to understand the state of the polymer melt by analyzing melt flow, heat distribution and structure as it flows through the manifold in order to design the optimal hot runner system. As plastic injection molding technology continues to move forward, the plastic injection molding industry will evolve accordingly, and the same medical device injection molding process will advance as well.

A large number of new entrants or the majority of small and medium-sized medical device injection molding companies in the industry have relatively poor infrastructure and lack advanced production and processing equipment. The key to increasing the development rate of the industry is the need to improve the overall level of special equipment for medical device injection molding. Many products have not yet developed product output to match the economic scale, which makes it difficult not only to develop a competitive advantage but also to improve profitability, which will limit the development of companies in the industry and even the industry as a whole.