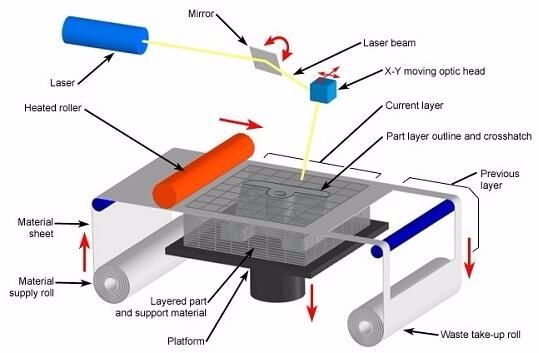

The LOM method uses material sheets (such as paper, plastic films or composite materials) as raw materials, and uses a carbon dioxide laser cutting system to cut out internal and external contours of the work pieces from the paper sheet coated with hot melt adhesive on the back according to the cross-sectional contour data extracted by the computer, while cross-cutting non-part areas to facilitate waste removal.

After cutting one layer, the feeding mechanism superimposes a new layer of paper sheets, and the worktable drives the formed work piece down (usually the thickness of the material is 0.1-0.2mm), and separates it from the belt-like sheet (material strip); The feeding mechanism rotates the receiving shaft and the feeding shaft to drive the material strip to move, so that the new layer moves to the processing area; the worktable rises to the processing plane; The paper-laying roller is hot-pressed, the number of layers of the workpiece is increased by one layer, and the height is increased by the size of the material thickness; then the section profile is cut on the new layer, and the parts are finally processed.

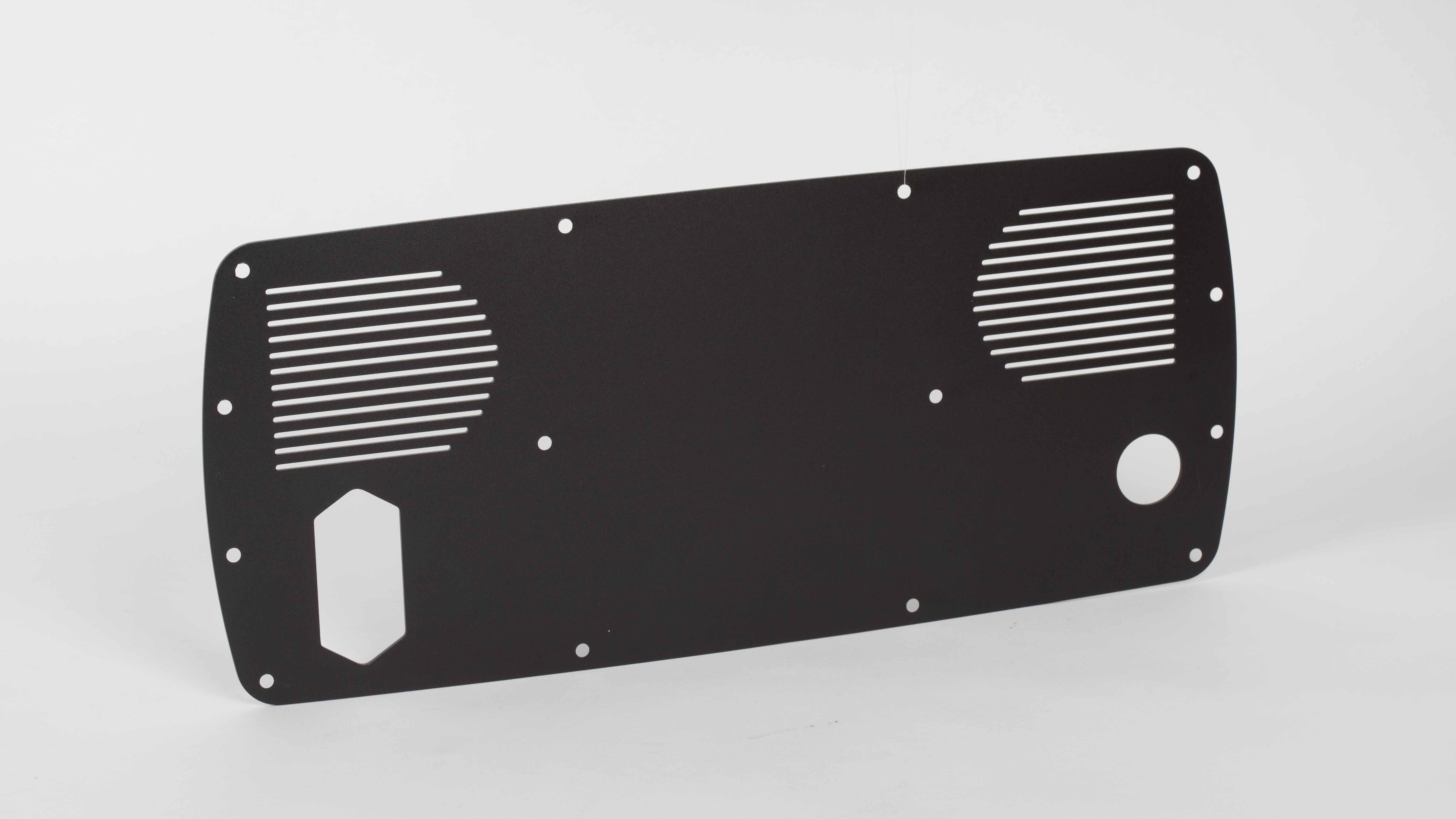

Mastars' industrial prototype service, with products and services that exceed customer expectations, is well-known in Europe and the United States, and has a high customer reputation. The industry covers a wide range of fields, including automobiles, motorcycles, health care, outdoor sports, home appliances, household goods, 3C Electronics, agriculture, stage lighting and outdoor sports, etc.

Mastars has a professional team of engineers and service teams, adhering to the spirit of craftsman in industry, to provide comprehensive solutions for your product development and production. At the same time, our company meets the customized order requirements of customers in various industries with the tenet of multi-variety, small batch and fast delivery.

So if you have any needs for prototype parts or mass production, please feel free to contact us, we are the most suitable partner that you have been looking for.

In the next chapter, we will continue to talk about