Mastars'

rapid prototyping service can provide various 3D printing prototyping services according to customers' needs, verify your designed, provide fast, efficient and cost-effective services, and lay the foundation for future mass production of your products.

Previous chapter: Talk about common 3D printing technologies 4. Today we will introduce common 3D printing technologies 5.

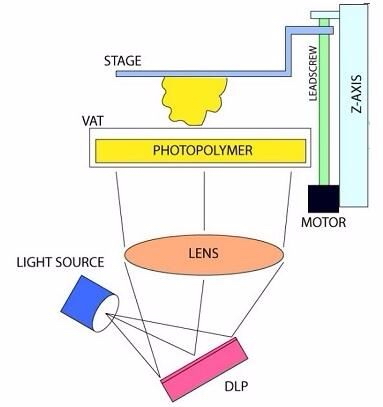

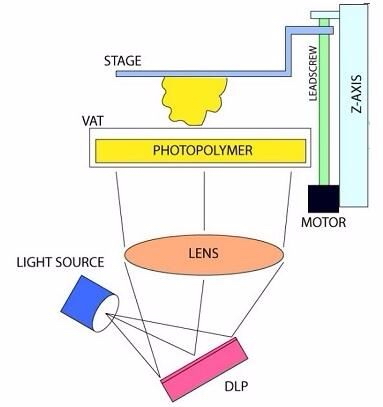

DLP process

DLP(Digital Light Processing) is a 3D printing technology emerging in recent years. It is a variant form of SLA and is similar to SLA molding technology. During the processing of the product, the cross section of the product is projected onto the surface of the liquid bright resin by using the digital micromirror element, so that the irradiated resin is uv-photocured layer by layer. DLP 3D printing is faster than the same type of SLA due to the fact that each layer is cured through a slide-like sheet. This technology is ideal for high-resolution molding.

The SLA process is mainly to focus a specific intensity of laser light on the surface of the

3D printing material to solidify it. SLA molding is mainly a process of point-to-line and line-to-surface forming gradually. Different from SLA, DLP technology mainly uses DLP projection, during the projection process, the entire surface of the laser is focused on the surface of the 3D printing material. Therefore, models with DLP technology print faster.

Advantages and disadvantages of DLP process

1) The product performance is similar to the SLA process, and the molding speed is faster.

2) Limited by the resolution of the digital light mirror, only smaller products can be printed.

DLP process has a long history of wax mold printing in the jewelry field, and its application is relatively mature. With the improvement of the resolution of digital light mirror, its application in industry, cultural and creative fields will be rapidly popularized.

Mastars' industrial prototype service, with products and services that exceed customer expectations, is well-known in Europe and the United States, and has a high customer reputation. The industry covers a wide range of fields, including automobiles, motorcycles, health care, outdoor sports, home appliances, household goods, 3C Electronics, agriculture, stage lighting and outdoor sports, etc.

Mastars has a professional team of engineers and service teams, adhering to the spirit of craftsman in industry, to provide comprehensive solutions for your product development and production. At the same time, our company meets the customized order requirements of customers in various industries with the tenet of multi-variety, small batch and fast delivery.

So if you have any needs for prototype parts or mass production, please feel free to contact us, we are the most suitable partner that you have been looking for.

In the next chapter, we will continue to talk about common 3D printing technologies 6.

Mastars Industries CO., LTD

Website: www.mastars.com

• Email: marketing@mastars.com

• Tel: +86 755-88210689

• Fax: +86 755-8821 0685

• Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China(518104)