China's Su Yiming won the gold medal in the snowboard men's big air finals at the Beijing Winter Olympic Games on February 15! He became China's youngest Winter Olympic champion. Snowboards are his most important equipment, and the high precision mold manufacturing, planer planing, thermal transfer printing, and post-surface treatment are all commonly used by Mastars. With more than 20 years of industry experience and strong technical level, Mastars provides the most reliable one-stop industrial manufacturing services to more than 800 well-known companies around the world.

In the first step, the strips are laid out in layers, glued together and compressed together. When the adhesive dries, they are cut lengthwise to form the core.

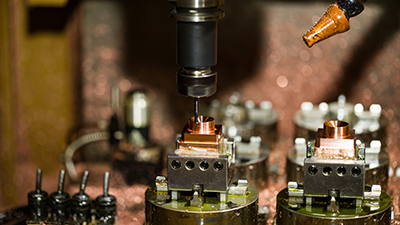

The second step is to use a jig to roughly estimate the shape of the board core before cutting with a band saw, and then fine-tune it with a special lathe. The pre-cut sidewalls are glued and held in a special vise before drying.

In the third step, before the edge metal is bent and fixed to the board according to the shape of the board, it is necessary to measure the shape of the board with the printed p-tex and fix it with another fixture. Then hit it with a hammer to make sure the bond is in place.

At the same time, the pattern of the bottom of the board is printed on the paper, and then pressed onto the bottom of the board by the thermal transfer function of the pressing machine. After cooling, it can act as a special protective film to protect the board during subsequent manufacturing.

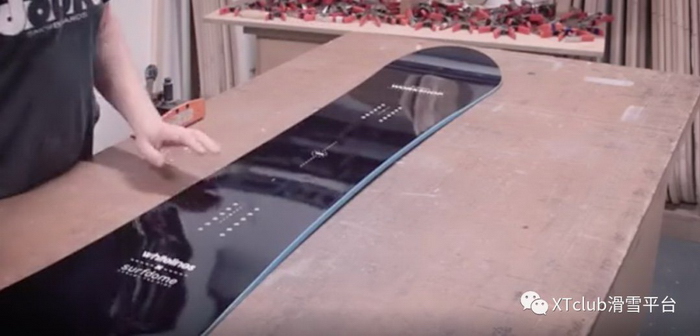

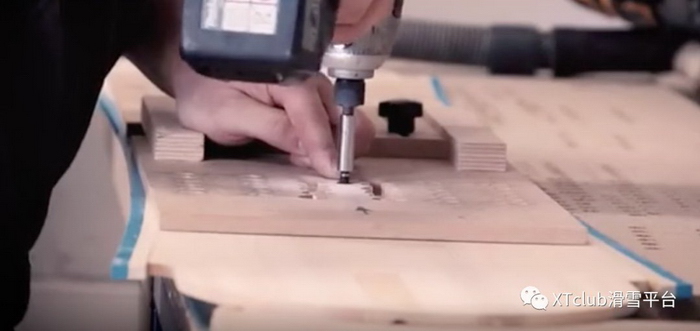

Then, before placing the board in the jig and running the planer again to shape the board's contours, holes are punched in the surface for binding nuts. Finally, the inserted nut is cemented into place with an adhesive. Once the glue on the side walls is done, the board can be sanded to the exact width with a planer.

All the individual snowboard components are now "laid" together. Each layer is evenly coated with epoxy, starting from the base and edge. At the same time, the glass fiber sheet is sandwiched between the bottom of the board, the core and the surface of the board. At this stage, additional fiberglass or carbon fiber strips can be strategically placed for additional strength and stiffness.

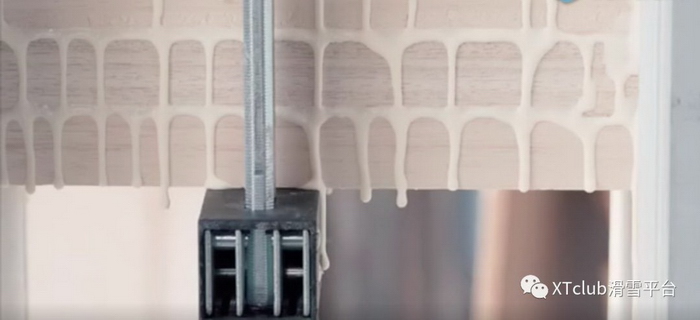

Once the "laid" is complete, the board is placed into a heat press with a profiled grinder on the bottom. The board is kept in a hot press and fixed as the epoxy resin solidifies under constant temperature and pressure. It is finally removed from the mold for precise adjustment.

Excess material on the board is trimmed away by a band saw and metal edge guidance.

Sanding

Before sanding the bottom of the board with a special sander with different roughness sandpaper, the edge of the board is sanded with a belt.