Mastars uses CNC technology to make prototypings and functional parts, providing customers with rapid prototyping services and high-precision parts production. CNC should be more and more widely used in today's industrial manufacturing services. Mastars has the world’s advanced 5-axis CNC machine tools and EDM machine tools, more than 20 years of industry experience, and a large number of excellent programming engineers to provide you with high-quality one-stop customized industrial manufacturing services.

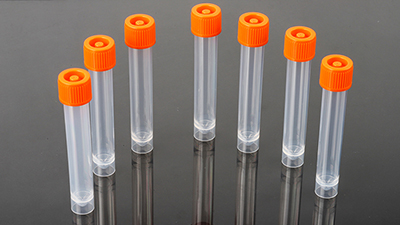

CNC is actually a CNC milling machine, which is a new type of processing technology. The main work is to automate processing through compiled processing programs. The machining method of CNC belongs to a kind of engraving and molding, and the processed precision parts are widely used in accessories of automobile, communication, medical, clock, mobile phone, computer and other industries.

Different from ordinary parts, precision parts are more precise and more suitable for some industries that require high precision. The machining of mechanical parts generally refers to the sum of the machining process of the parts and the assembly process of the machine. Other processes are called auxiliary processes, such as transportation, storage, power supply, equipment maintenance, etc.

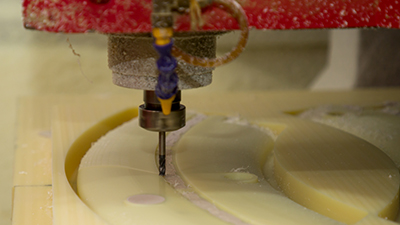

Traditional machining is accomplished by manual operation of ordinary machine tools. During the machining, the machine tool is controlled by the crank handle to cut metal, and the caliper and other tools are used to measure the size of the product, which is not so good in the machining precision and consistency of the product. Modern industry already operates with CNC, which can directly and automatically process any product and part according to a program written by a technician.

CNC machining is processing with machining tools controlled by computer programs, and CNC machine tools are programmed and controlled by CNC machining language, usually G code. The CNC machining G code language informs the CNC machine tool which Cartesian position coordinates the machining tool adopts, and controls the feed rate and spindle speed of the tool, also controls tool converter, coolant and other functions.

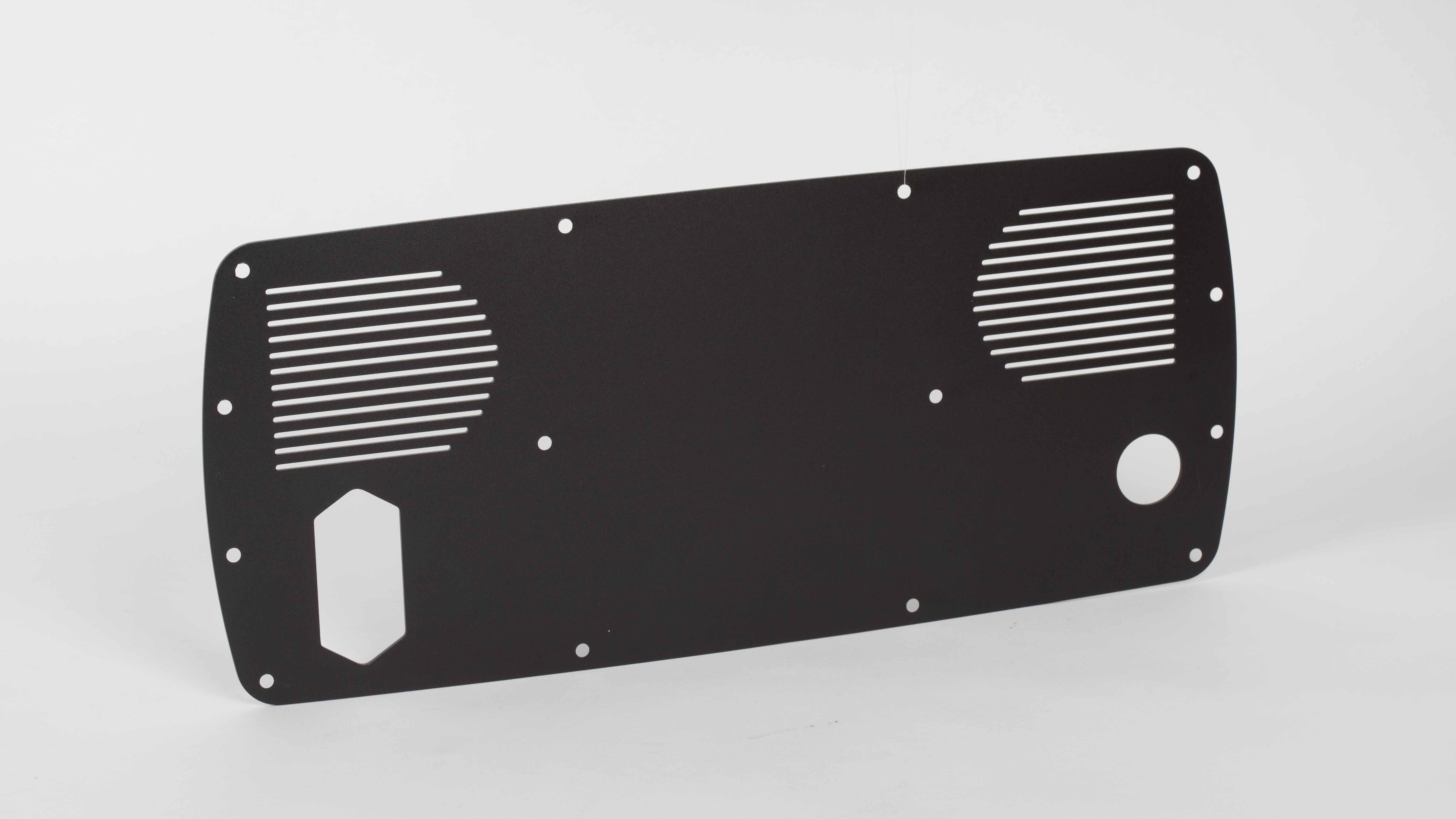

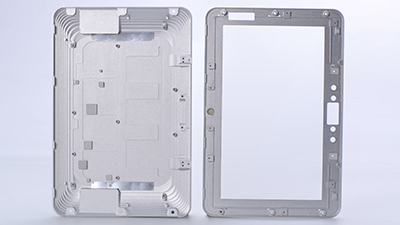

CNC fine machining means that the precision marked on the production and processing drawings is high and requires fine machining. The ultra-fine processing equipment of mechanical processing manufacturers mainly includes: CNC machining centers, fine grinders and CNC lathes.

The CNC machining center has high precision and has unique advantages for the processing of high precision, complex and small batch parts; the fine grinder is one of the fine processing equipment, mainly for the processing of quenched parts; the CNC lathe is also an active processing equipment, it is generally used to process round parts such as shafts and rods. Normally, it has the advantages for the processing of special precision requirements or small batch parts.

If your rapid prototypings or functional parts need CNC machining, please contact Mastars, we will develop the best solution for you, provide you with products that exceed your expectations and one-stop service.