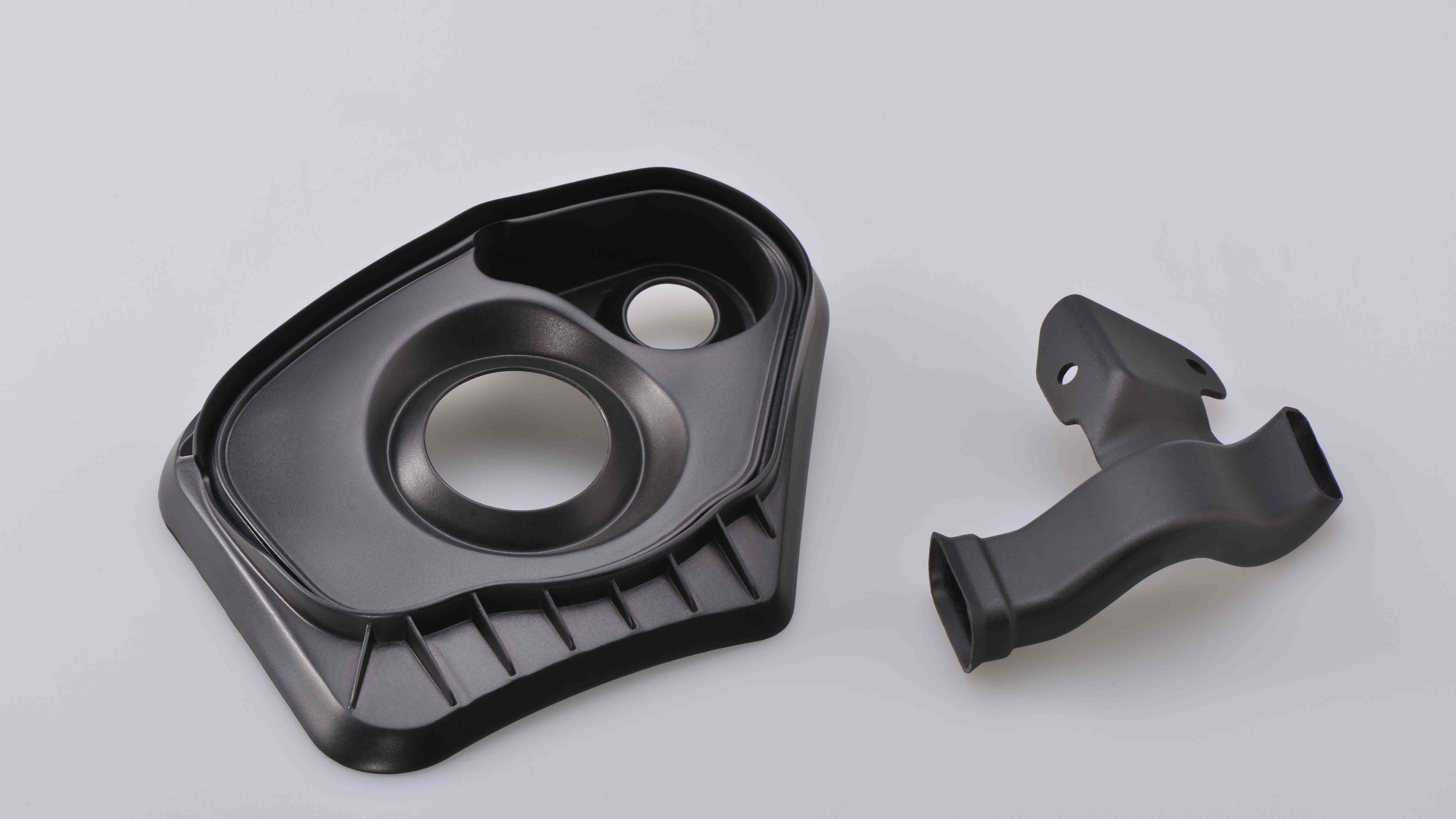

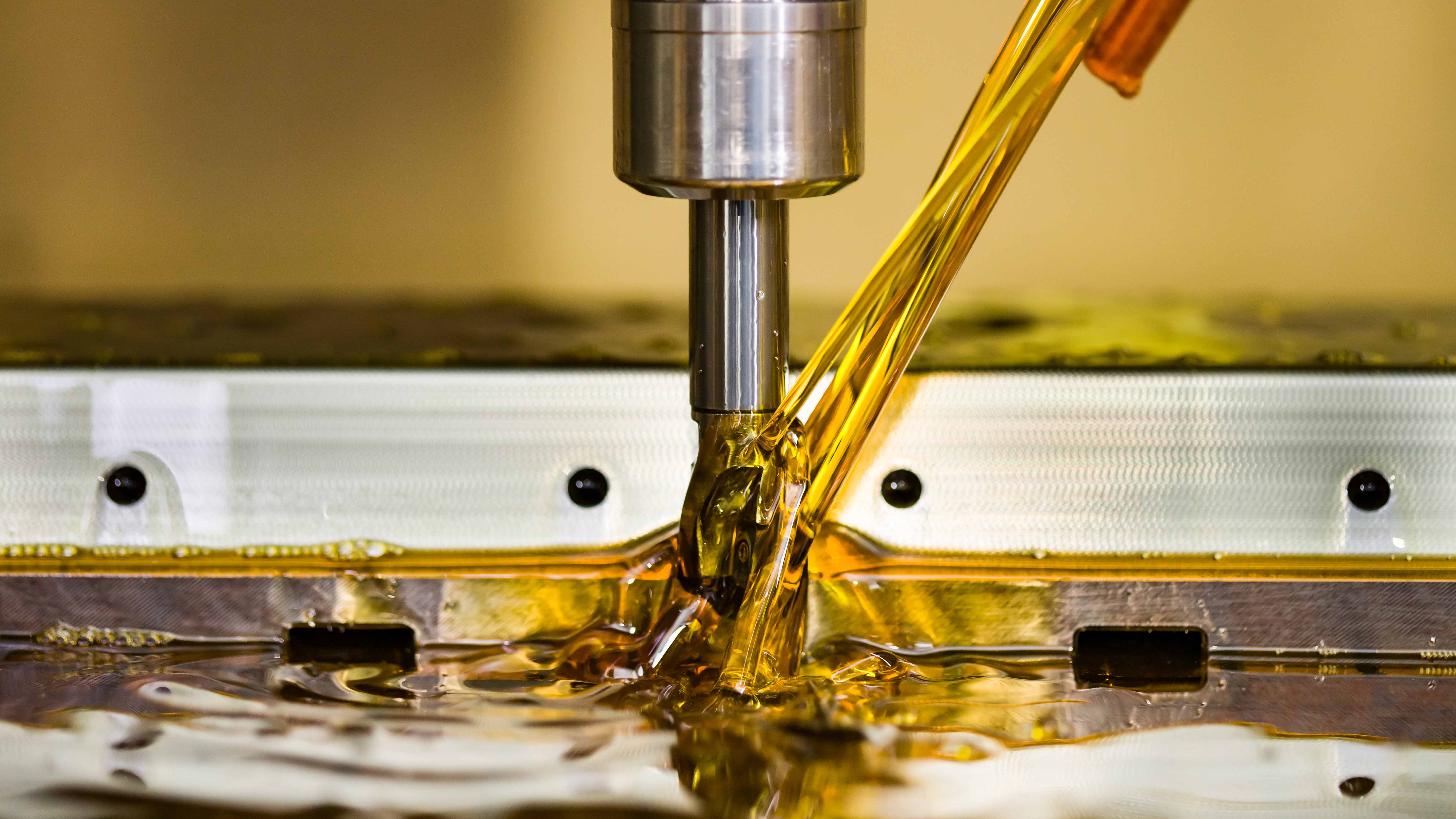

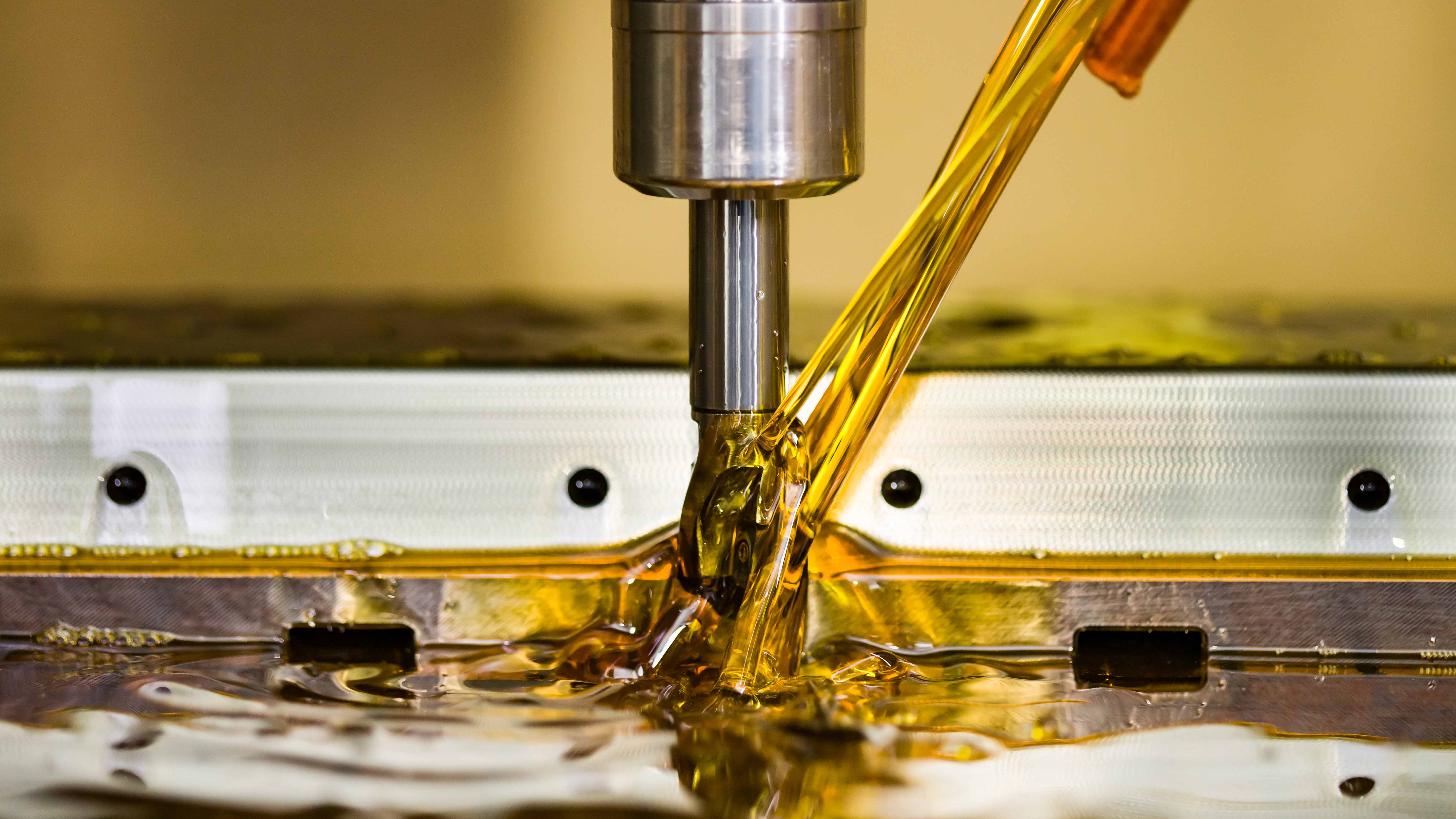

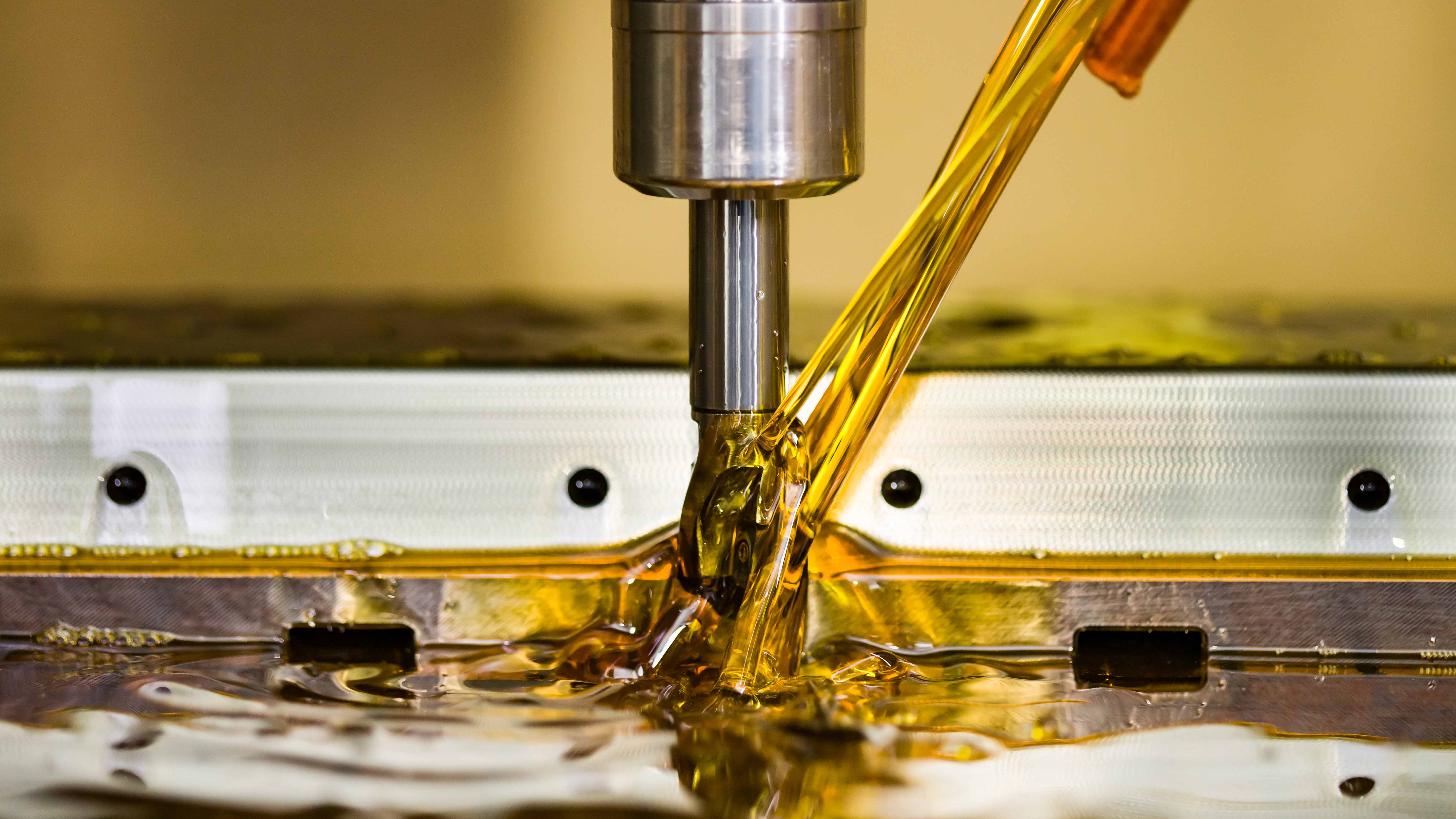

Mastars is a global company that provides one-stop customized industrial manufacturing services. Its business scope is as extensive as CNC applications, and CNC is one of its main prototyping machining processes in addition to precision molding, die casting, vacuum casting, sheet metal prototyping.

1、 Workpiece overcut

reason:

The strength of the tool is too long or too small, resulting in the tool bouncing.

Improper operator operation.

Uneven cutting allowance. (e.g. 0.5 for the side surface and 0.15 for the bottom surface)

Improper cutting parameters. (e.g. too large tolerance, too fast SF setting, etc.)

improve:

Principle of using knife: it can be big but not small, short but not long.

Add angle clearing procedure, and try to keep the margin even. (the margin of side and bottom shall be consistent)

Reasonably adjust the cutting parameters and round the corners with large allowance.

Using the SF function of the machine tool, the operator can fine tune the speed to achieve the best cutting effect of the machine tool.

2、 Split problem

reason:

Inaccurate manual operation by the operator.

There are burrs around the die.

The centring rod is magnetic.

The four sides of the mold are not vertical.

improve:

The manual operation shall be carefully checked repeatedly, and the points shall be at the same point and height as far as possible.

Use oilstone or file to remove burrs around the mold, wipe it with rags, and finally confirm by hand.

Demagnetize the centring rod before centring the mold. (ceramic centering rod or others can be used)

Check whether the four sides of the mold are vertical. (the verticality error needs to be reviewed with the fitter)

3、 Tool setting problem

reason:

Inaccurate manual operation by the operator.

Tool clamping error.

The blade on the throwing knife is wrong. (Throwing Knife itself has certain error)

There is error between R knife, flat bottom knife and throwing knife.

improve:

The manual operation shall be carefully checked repeatedly, and the tool setting shall be at the same point as far as possible.

When clamping the tool, blow it with an air gun or wipe it with rags.

A blade can be used when the blade on the throwing knife needs to measure the tool bar and smooth the bottom surface.

A separate tool setting program can avoid the error between R knife, flat knife and flying knife.

4、 Crash - Programming

reason:

The safety height is insufficient or not set. (the tool or collet collides with the workpiece during rapid feed G00)

The tool on the program sheet and the actual program tool are written incorrectly.

The tool length (blade length) and the actual machining depth on the program sheet are written incorrectly.

The depth z-axis retrieval and the actual z-axis retrieval on the program sheet are written incorrectly.

Coordinate setting error during programming.

improve:

Accurate measurement of the height of the workpiece also ensures that the safety height is above the workpiece.

The tool on the program sheet shall be consistent with the actual program tool. (try to use automatic program list or picture program list) add wechat: yuki7557 send a macro program tutorial

Measure the actual machining depth on the workpiece, and write down the length and blade length of the tool on the program sheet. (generally, the tool clamp length is 2-3mm higher than the workpiece, and the blade length is 0.5-1.0mm)

Take the actual z-axis data on the workpiece and write it clearly on the program sheet. (this operation is generally manual operation, which should be checked repeatedly after writing)

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

+86 18100294997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China