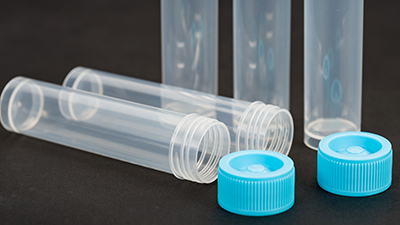

- [Medical Device Industry]Solution for Medical and health parts06 Jan,2022

- The automotive industry represents a large part of the customer base and we believe to provide the highest quality solution for our customers. Our goal is to exceed your expectations and help you succeed in the market – this mission makes our customers trust.

-

- [Household Appliances Industry]Household Appliances Industry21 Dec,2021

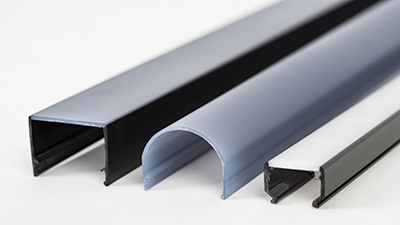

- Mastars produced injection molds and tooling and decorative paint finishes for domestic and business-machine enclosures. Mastars's experience covers a wide range of domestic and commercial applications, from vacuum air to digital printers.

-

- [FAQ]What Is Vacuum Casting? Definition, methods, process, comparison31 Oct,2025

- Vacuum Casting, also known as Polyurethane (PU) Casting or Urethane Casting, is an advanced manufacturing process used to produce high-quality, functional prototypes and end-use parts in small to medium volumes (typically 10-50 parts, but up to 100+). It is renowned for replicating the properties of injection-molded plastics without the high cost and lead time of production-grade tooling.

-

- [FAQ]Metal Injection Molding (MIM): A Detailed Overview31 Oct,2025

- Metal Injection Molding (MIM), also known as Powder Injection Molding (PIM), is an advanced manufacturing process that combines the design flexibility of plastic injection molding with the material performance of wrought metals.

-

- [FAQ]Glossary of Plastic Injection Molding Terms31 Oct,2025

- An A to Z guide to terminologies in Injection tooling.Here is a detailed English-language guide to the professional terminology associated with Injection Tooling (the mold).

This glossary is organized by the function and location of components within the mold system.

-

- [FAQ]Terminology of the Injection Molding Industry31 Oct,2025

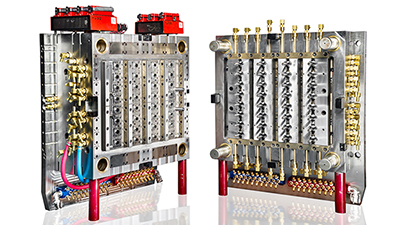

- Common Terms Within The Injection Molding Industry.Plastic injection molding is a manufacturing process wherein plastic is injected into aluminum, or steel molds and squeezed under high pressure to come up with the desired shape of the product

-

- [Blog]Cross-Industry Workflow Strategies for Prototyping10 Oct,2025

- Prototyping is essential for turning ideas into tangible products across Australia's diverse industries. From Melbourne's automotive suppliers to Sydney's medical innovators, selecting the right method can save time, cut costs, and meet ind...

-

- [Blog]Industrial Design Prototyping with 3D Printing03 Oct,2025

- Looking to speed up your product development? Here's what you need to know: 3D printing is transforming prototyping. It’s faster, more cost-effective for small runs, and ideal for testing complex designs. But traditional methods like ...

-

- [FAQ]Mastars: Detail Guide About Aluminum Injection Molding16 Mar,2022

- Prototypes or real products are produced by the aluminum injection molding technique. The aluminum tooling technique is used for the process of aluminum injection molding. It is the process based on the injection molding technique. Mastars is also a metal prototype maker.

-

- [Blog]Thermoset Injection Molding Process Explained18 Sep,2025

- Thermoset Injection Molding Process Explained Thermoset injection molding is a critical manufacturing process widely used in industries such as automotive, aerospace, consumer electronics, and medical devices. Unlike thermoplastics, thermos...

-

- [Blog]Why OEMs Use 3D Printing for Low-Volume Production16 Sep,2025

- Why OEMs Use 3D Printing for Low-Volume Production | Mastars Lower Tooling Costs Faster Lead Times Traditional methods like injection molding require expensive tooling and molds. For small batches or prototypes, the tooling cost alone can ...

-

- [Blog]Best Practices for Injection Moulded Snap-Fit Joints09 Sep,2025

- Snap-fit joints are a reliable and cost-effective way to assemble plastic parts in injection moulding. They interlock components through elastic deformation, eliminating the need for screws or adhesives. Here's what you need to know: Mate...

-

- [Blog]Vacuum Casting: Key Advantages and Drawbacks06 Sep,2025

- Vacuum casting is a practical manufacturing method popular in Australia for prototyping and small-scale production. It uses silicone moulds and vacuum pressure to create high-quality parts from polyurethane resins. This method is commonly u...

-